Traction device and rail car

A traction device and traction pin technology, applied in the field of rail car traction, can solve the problems of affecting the transmission of traction force and braking force, easy to produce impact, inconvenient for rescue and transition, etc., and achieve the effect of effective transmission and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

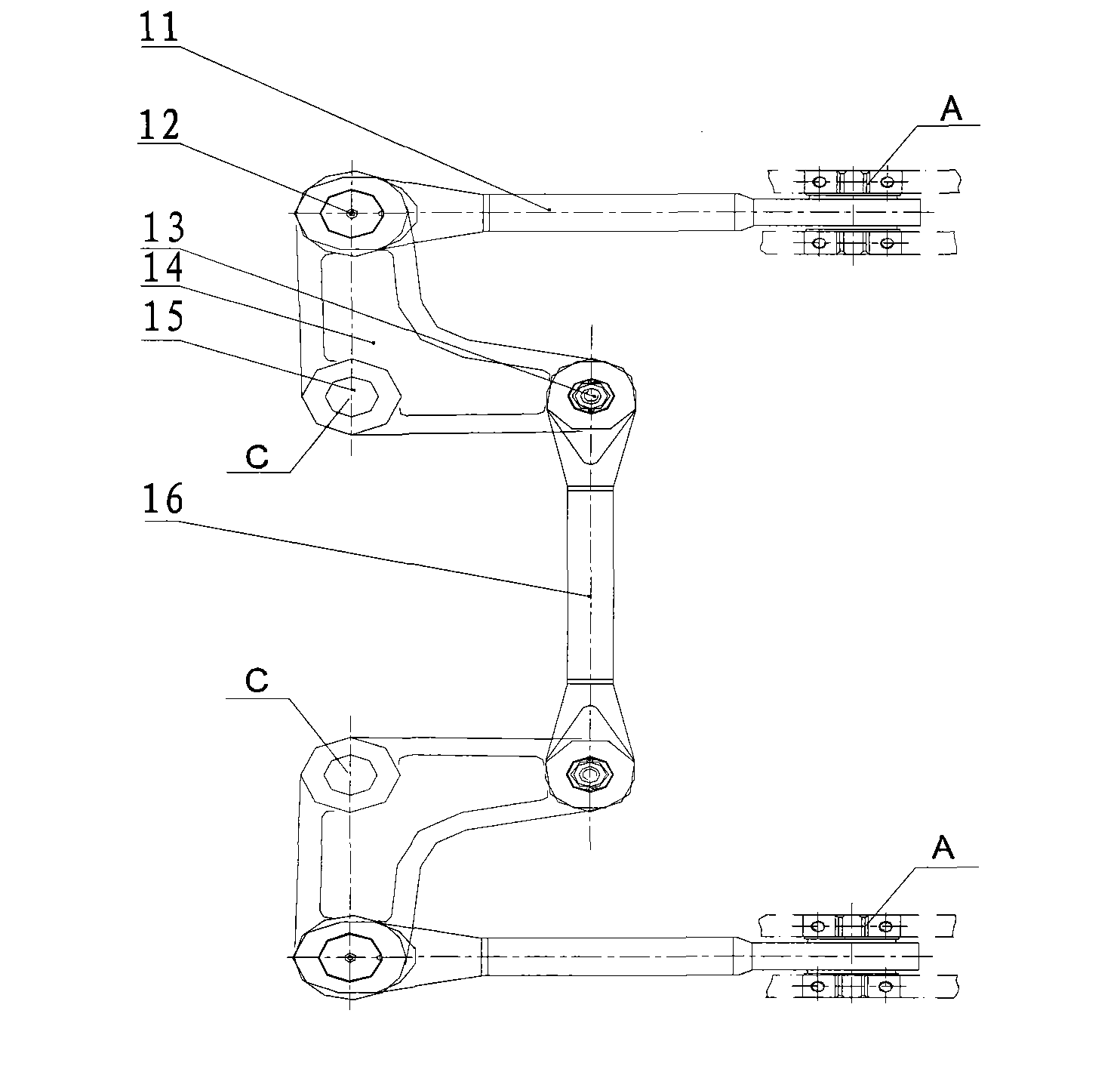

[0033] The technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

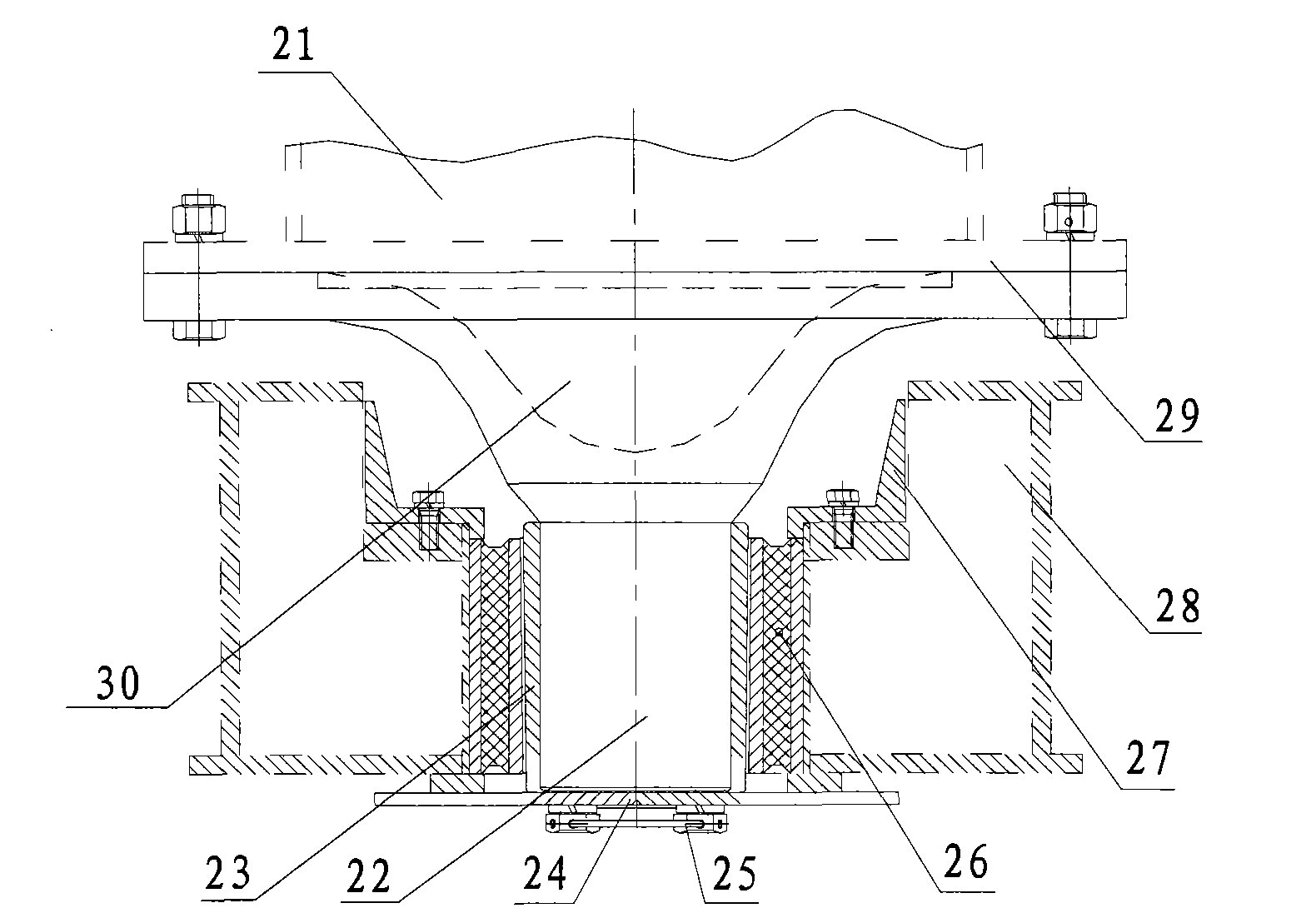

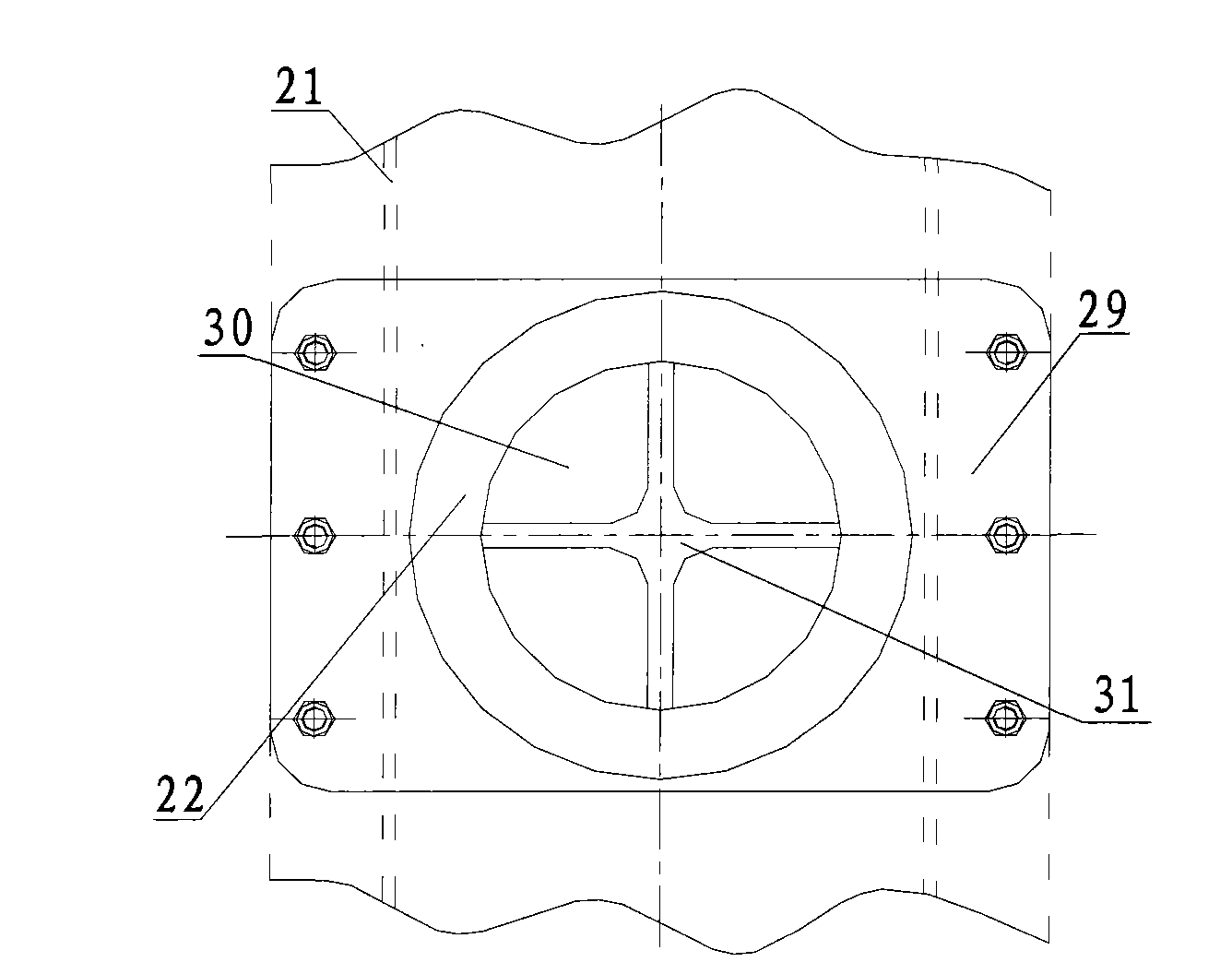

[0034] figure 2 Schematic diagram of the structure of the traction device provided by the embodiment of the present invention, image 3 for figure 2 Top view of the towing device. Such as figure 2 As shown, the traction device can include a vehicle body fixing part 29, an alloy bushing 23, a rubber traction pin joint 26, a traction pin 22 and a bogie fixing part 27, wherein the vehicle body fixing part 29 is used to connect with the vehicle body drawing beam 21 For fixed connection, at least one traction pin 22 may be provided on the side of the vehicle body fixing member 29 away from the vehicle body. In practical applications, the number of traction devices on each vehicle body can be two sets, and in each set of traction devices, one or more traction pins 22 can be set on the side of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com