Stitching method of double-sided cross stitch

A technology of cross stitch and making method, which is applied to the mechanism of embroidery machine, embroidery machine, textile and paper making, etc., can solve the problems of beauty on both sides, time-consuming and labor-intensive, unfavorable automatic processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

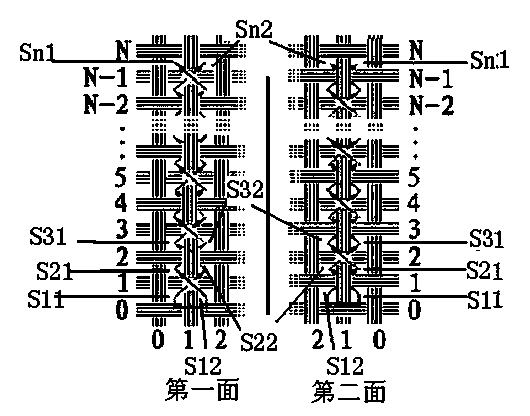

[0054] As shown in Figure 1, the lower left corner of the starting cell in the first column is S11, the lower right corner is S12, the lower left corner of the second cell in the first column is S21, and the lower right corner is S22, and the third cell in the first column The lower left corner of the grid is S31, and the lower right corner is S32. The upper left corner of the first column and the last row, that is, the Nth row, is Sn1 and the upper right corner Sn2. The embroidery methods include:

[0055] (1) There are cross-stitch needles at both ends of the embroidery thread, and the cross-stitch needles respectively pass through the lower left corner and the lower right corner of the starting cell of the cross-stitch fabric. The embroidery thread is equalized into two parts, and the cross-stitch stitch The needle stays at S11 and S12 on the first side of the cross-stitch fabric;

[0056] (2) Align the two cross-stitch needles, and then respectively go down to the lower le...

Embodiment 2

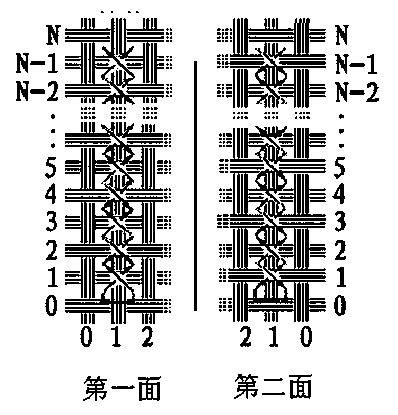

[0062] As shown in Figure 2, the lower left corner of the starting cell in the first column is S11, and the lower right corner is S12; the lower left corner of the second cell in the first column is S21, and the lower right corner is S22; the starting cell in the second column The lower left corner of the cell is S12, the lower right corner is S13, the lower left corner of the second cell in the second column is S22, and the lower right corner is S23, the upper left corner of the last row of the first column (that is, the Nth row) is Sn1 and the upper right corner Sn2, and Embroidery methods include:

[0063](1) There are cross-stitch needles at both ends of the embroidery thread, and the cross-stitch needles respectively pass through the lower left corner and the lower right corner of the starting cell of the cross-stitch fabric. The embroidery thread is equalized into two parts, and the cross-stitch stitch The needle stays at S11 and S12 on the first side of the cross-stitch...

Embodiment 3

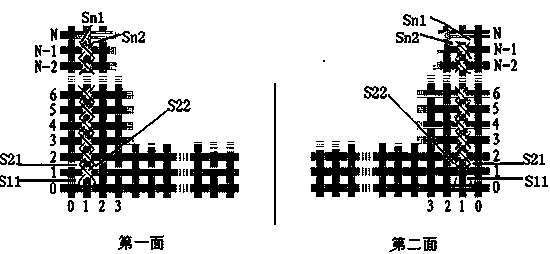

[0073] As shown in Figure 3, the cross-stitch fabric has columns 1 to M from left to right, M is a natural number not less than 3, the lower left corner of the starting cell in the first column is S11, the lower right corner is S12, and the penultimate column That is, the lower left corner of the second cell in the M-1 column is S2 (m-2) and the upper right corner S2 (m-1), and the lower left corner of the last column, which is the starting cell of the M column, is S1 (m- 1) The lower right corner is S1m, and its embroidery methods include:

[0074] (1) There are cross-stitch needles at both ends of the embroidery thread, and the cross-stitch needles respectively pass through the lower left corner and the lower right corner of the starting cell of the cross-stitch fabric. The embroidery thread is equalized into two parts, and the cross-stitch stitch The needle stays at S11 and S12 on the first side of the cross-stitch fabric;

[0075] (2) Align the two cross-stitch needles, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com