A feeding conversion mechanism

A conversion mechanism and feeding technology, applied in the direction of conveyor objects, transportation and packaging, can solve problems such as inability to material, low efficiency, transmission, etc., and achieve the effect of improving stability and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

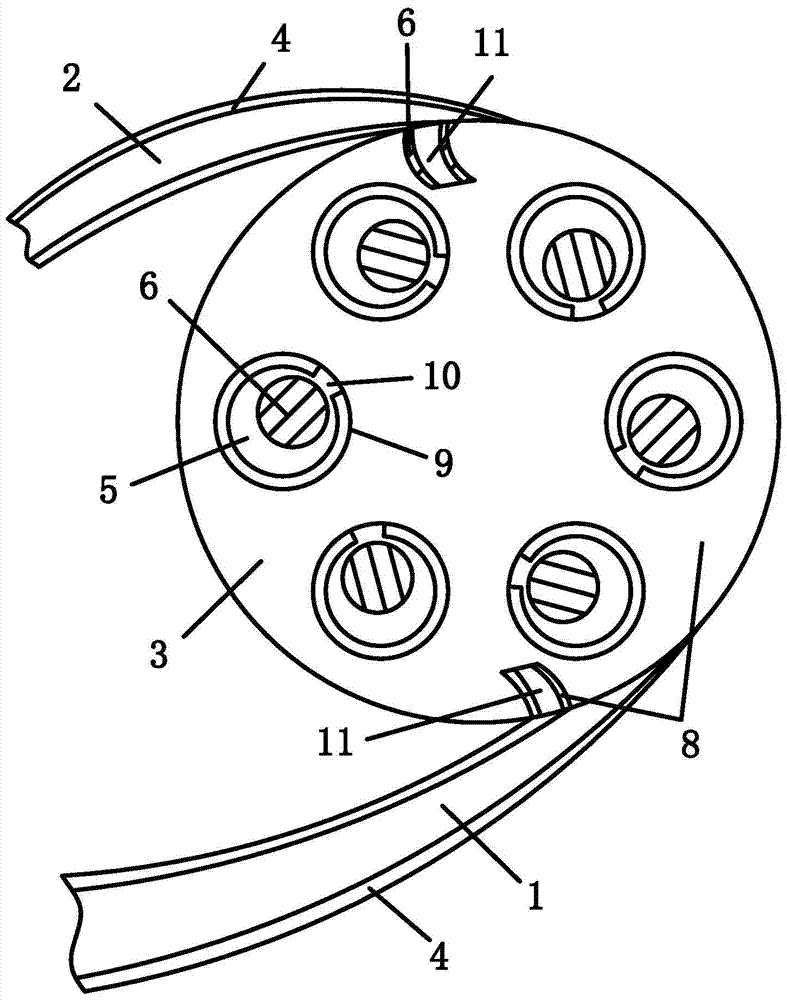

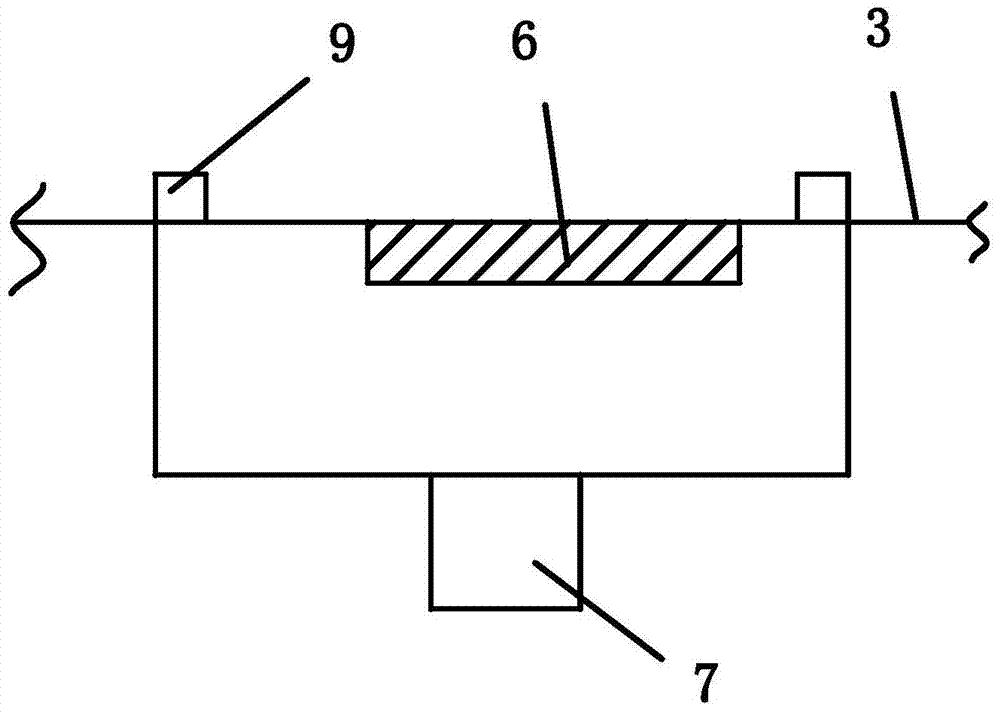

[0015] refer to Figure 1-2 , the present embodiment includes a feed channel 1 and a discharge channel 2, a circular turntable 3 is arranged between the feed channel 1 and the discharge channel 2, and the feed channel 1 and the discharge channel 2 Drive wheels 4 are arranged on both sides of the circular turntable 3, and six object stages 5 are evenly arranged on the circular turntable 3 with the center as a symmetrical axis. 6. A rotary motor 7 is provided on the bottom of the stage 5, and a polytetrafluoroethylene layer 8 is provided on the surface of the circular turntable 3. The feed channel 1 and the discharge channel 2 are connected to the circular turntable 3 tangentially. The stage 5 and the rubber layer 6 are circular. The minimum distance between the outer edge of the stage 5 and the outer edge of the circular turntable 3 is 15% of the diameter of the circular turntable, which can increase the force applied to the material during the material transfer process while ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com