Hydraulic pressure revolving shaft device

A rotating shaft and hydraulic technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of reducing the service life of the rotating shaft, generating noise, affecting users, etc., and achieving the effect of solving the problem of non-durability, noise generation, and friction elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

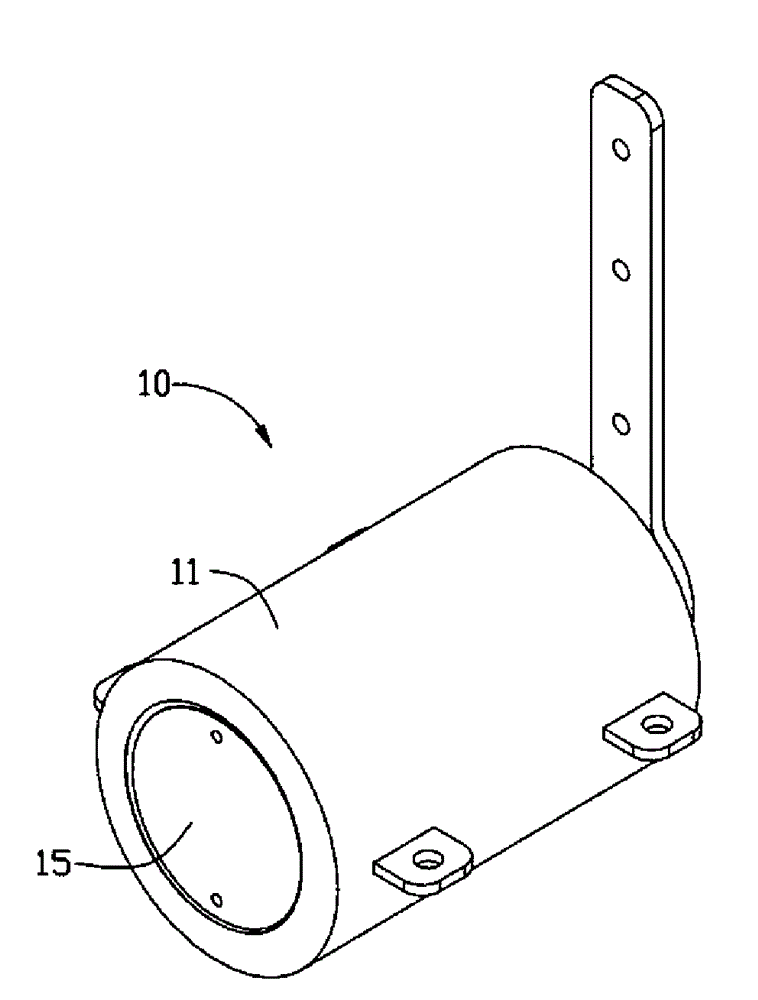

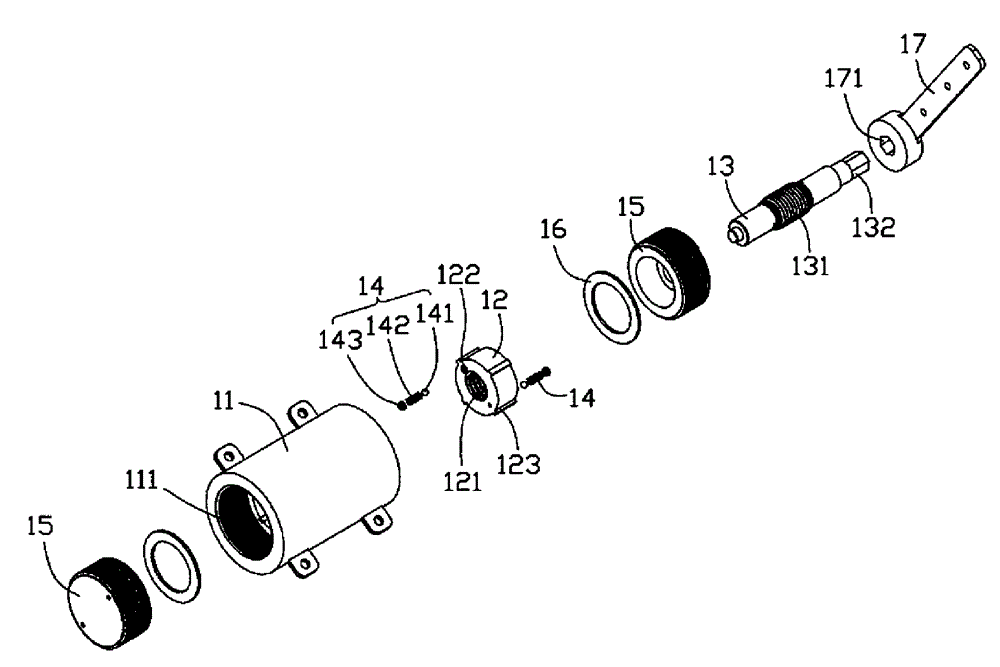

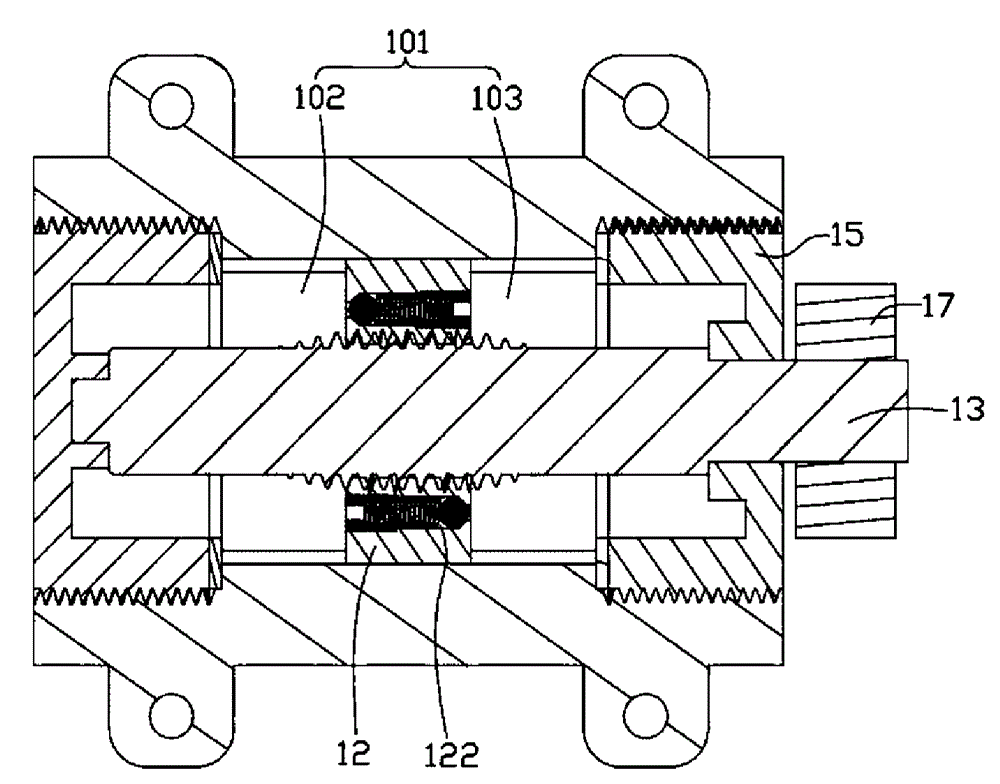

[0011] Please refer to Figure 1 to Figure 3 , which discloses the hydraulic shaft device 10 according to the first embodiment of the present invention. The rotating shaft device 10 includes a casing 11 , a piston 12 , a transmission shaft 13 , an elastic block 14 and a bearing 15 . The bearings 15 are mounted on both ends of the housing 11 and form a sealed chamber 101 with the housing 11. The sealed chamber 101 is filled with liquid. The piston 12 divides the sealed chamber 101 into a first chamber 102 and a second chamber 103. The transmission shaft 13 is mounted on the piston 12 and passes through the sealed chamber 101.

[0012] The shell 11 is cylindrical, and the inner surface of the shell 11 is formed with a plurality of longitudinal guide grooves 111 along the axial direction, and the two ends of the inner surface of the shell 11 are threaded, and the circumferential surface of the shell 11 is provided with a plurality of fixed A member 113, and a fixing hole is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com