Welded ball pin, and method for the production thereof

A ball pin, ball technology, applied in the direction of manufacturing tools, welding equipment, connections, etc., can solve the problems of increasing complexity and damage to the concentricity of the ball, and achieve the effect of improving service life, improving load bearing capacity, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

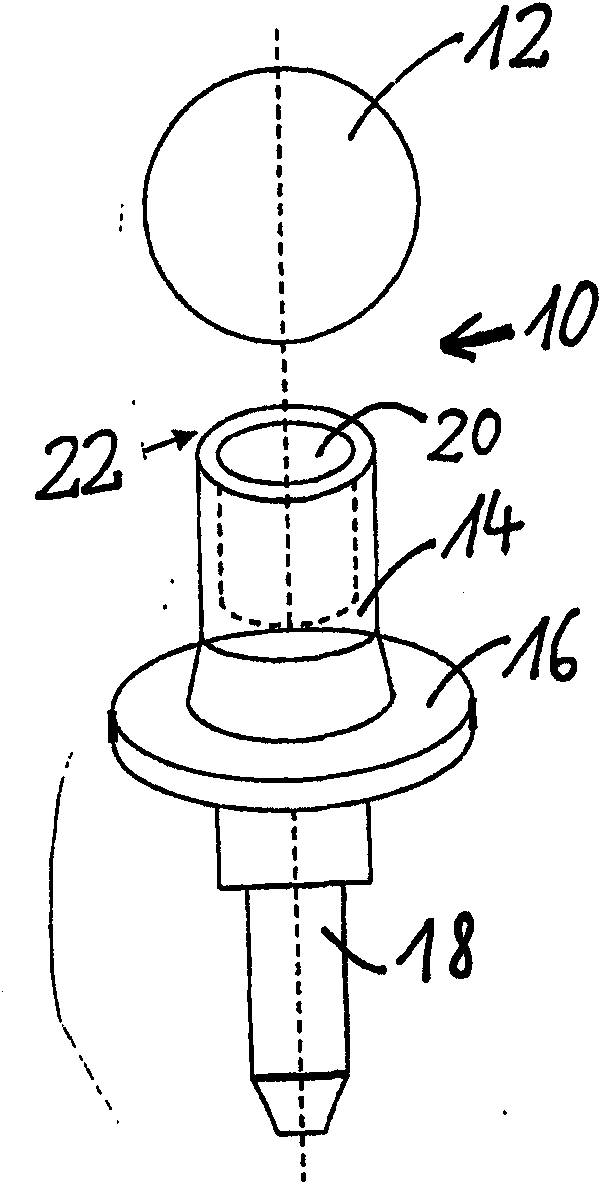

[0026] figure 1 Illustrated is an exploded perspective view of a welded ball pin in accordance with the present invention (before the ball and shaft are welded together).

[0027] The solder ball pin 10 according to the invention comprises a ball 12 which is welded to a shaft 14 . The shaft 14 then transitions into a force sensing element 16 and an externally threaded support 18 . Since these elements may correspond to embodiments in the prior art and do not substantially contribute to the object of the present invention, these elements are not described in detail here.

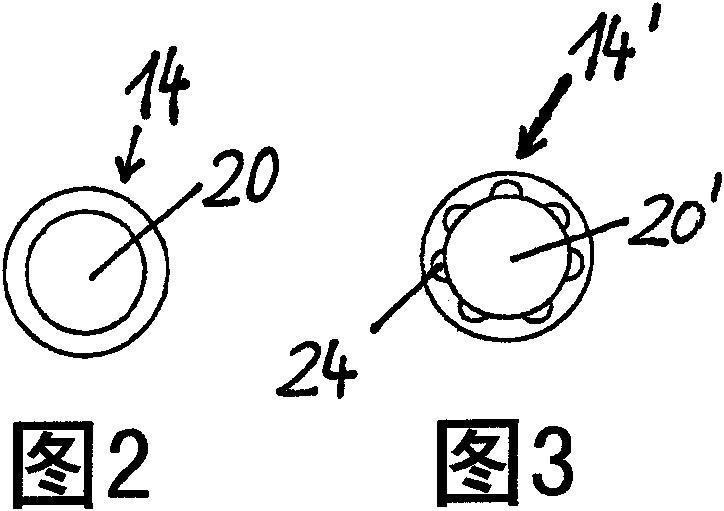

[0028] According to the invention, however, the shaft 14 is configured as a hollow cylinder with an inner cylindrical cavity 20 . Thus, the welding between the ball 12 and the shaft 14 takes place only at the annular portion 22 where the hollow cylindrical shaft 14 is in contact with the ball 12 . Nevertheless, this arrangement is much more durable than the prior art in which a shaft 14 made of solid bar s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com