Apparatus for labeling containers, comprising a printer unit

A technology for labeling and equipment, applied in the directions of labels, labeling machines, packaging, etc., can solve the problems of loss of device efficiency, difficult to implement assembly procedures, and slowdown in speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

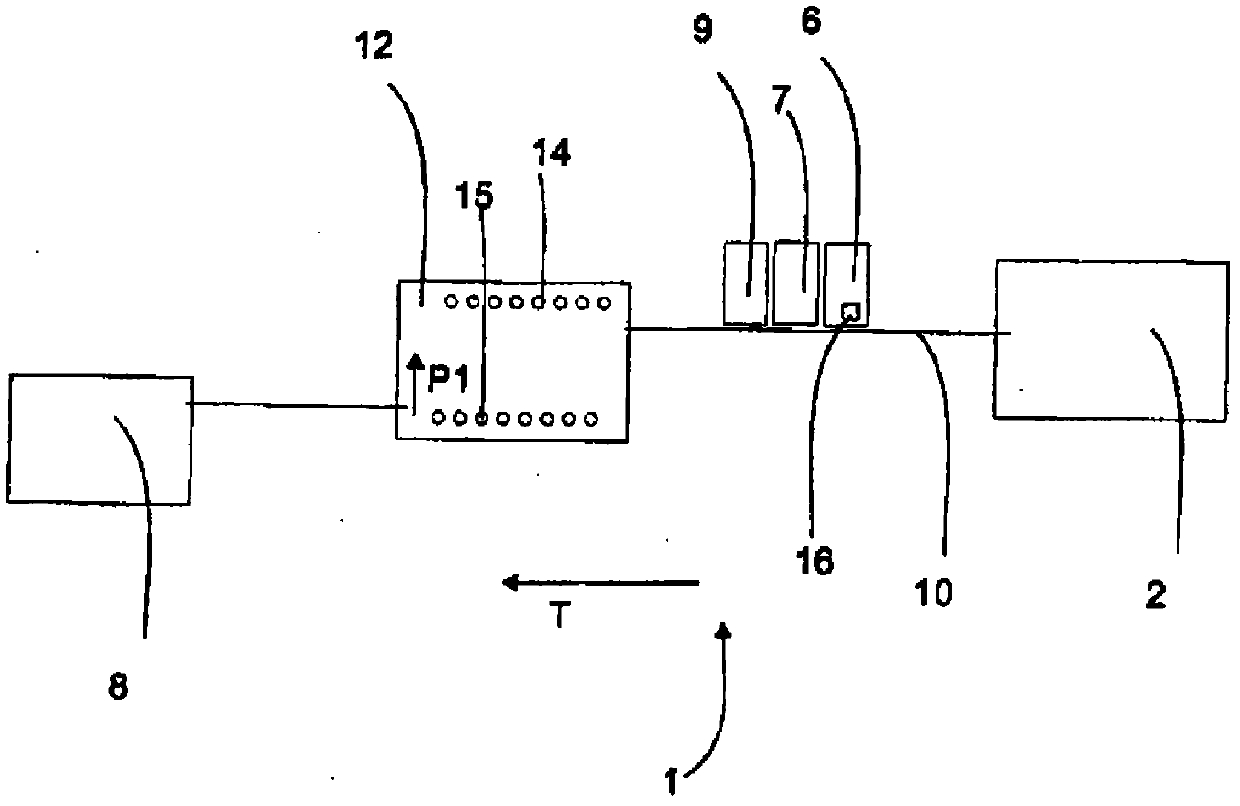

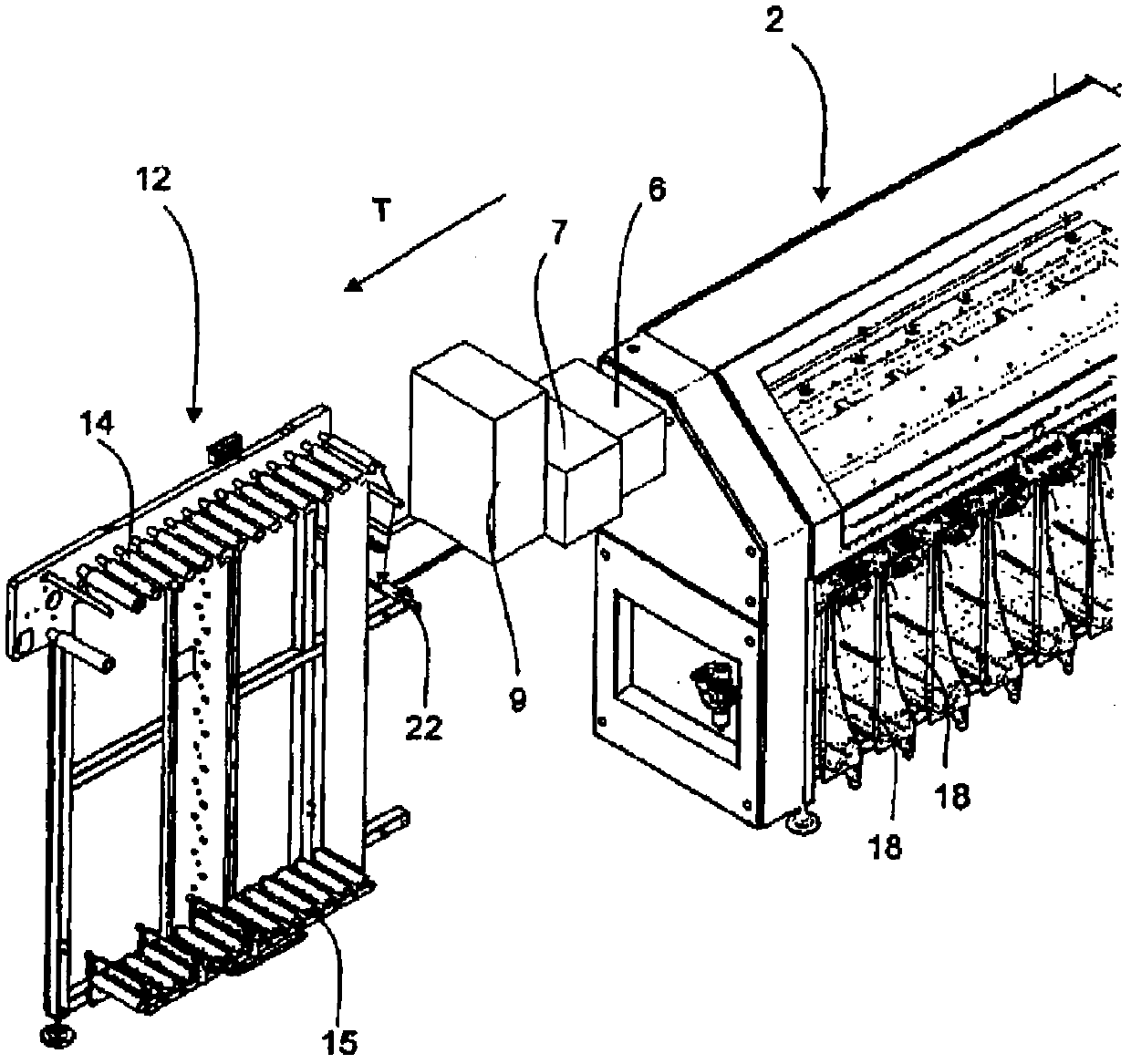

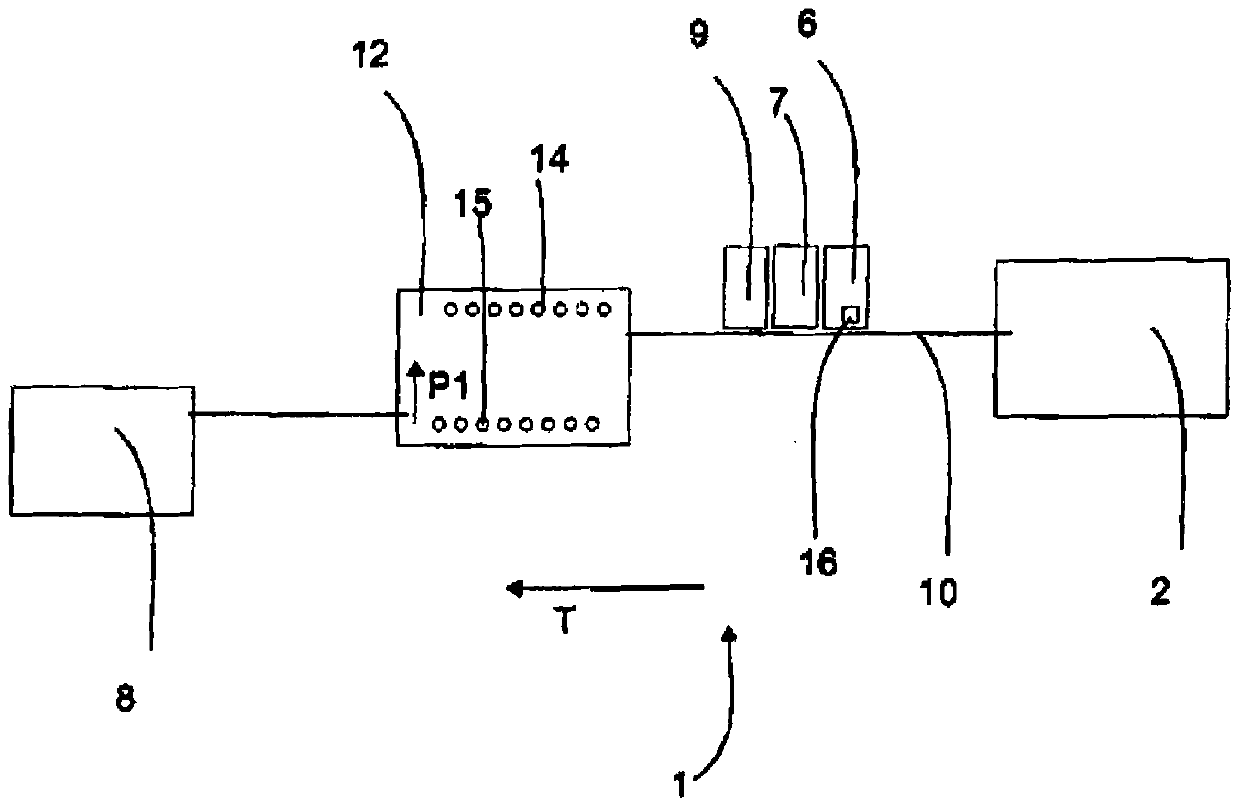

[0033] figure 1 is a very schematic diagram of an apparatus 1 for labeling containers according to the invention. This device 1 has a storage unit 2 for label material 10 in which eg a plurality of label rolls are arranged, from which label material 10 can be unwound.

[0034] After this storage unit 2 , the label stock reaches the printing unit 6 in the transport direction T to the left and is transported via the printing unit 6 . In this case, this printing device 6 has printing elements, such as inkjet printing elements 16 , for example. After this printing element, there is provided a drying device 7 which dries the label material or the print applied thereto, respectively. In this case, such drying can be achieved with UV light, for example. In addition, checking means 9 are provided for checking to see if the imprint is correctly applied to the label material 10 . Furthermore, it is also possible for the printing unit 6 or even a further printing unit to attach marki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com