Hair remover

A hair removal and outer blade technology, applied in metal processing, etc., can solve problems such as noise, increased interference between outer blade and inner blade, and difficulty in bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A hair remover according to an embodiment of the present invention will now be described with reference to the accompanying drawings.

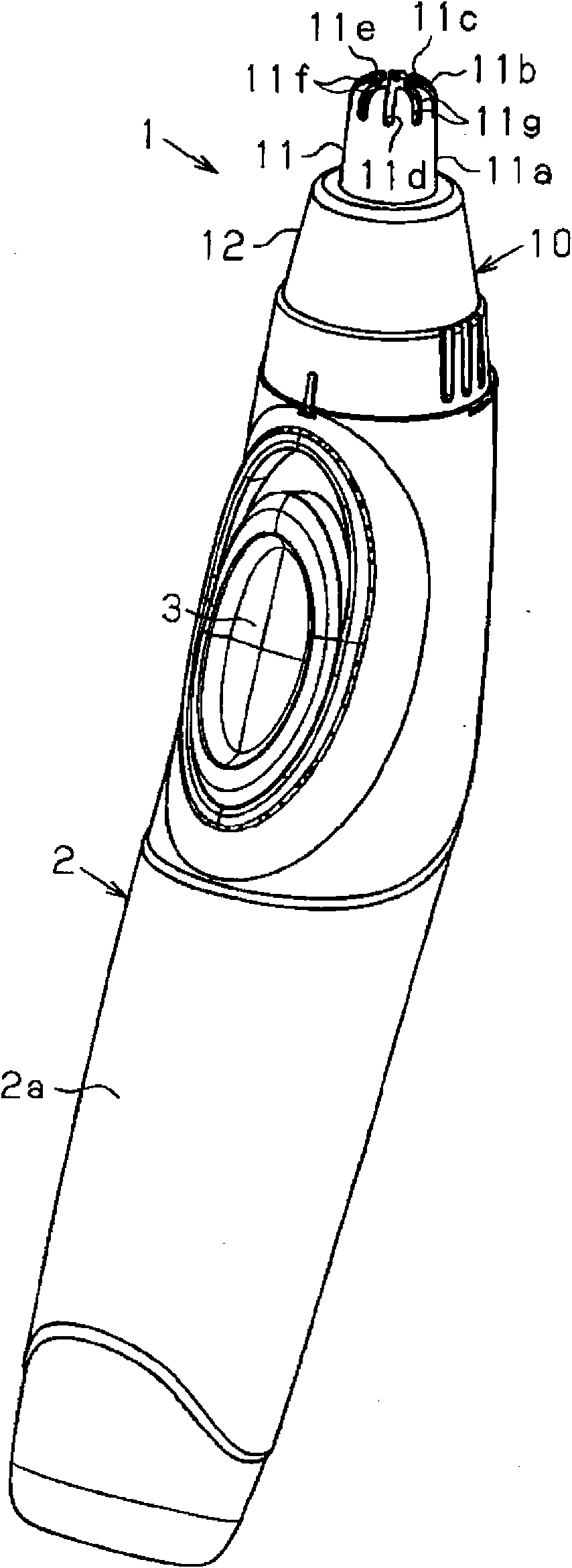

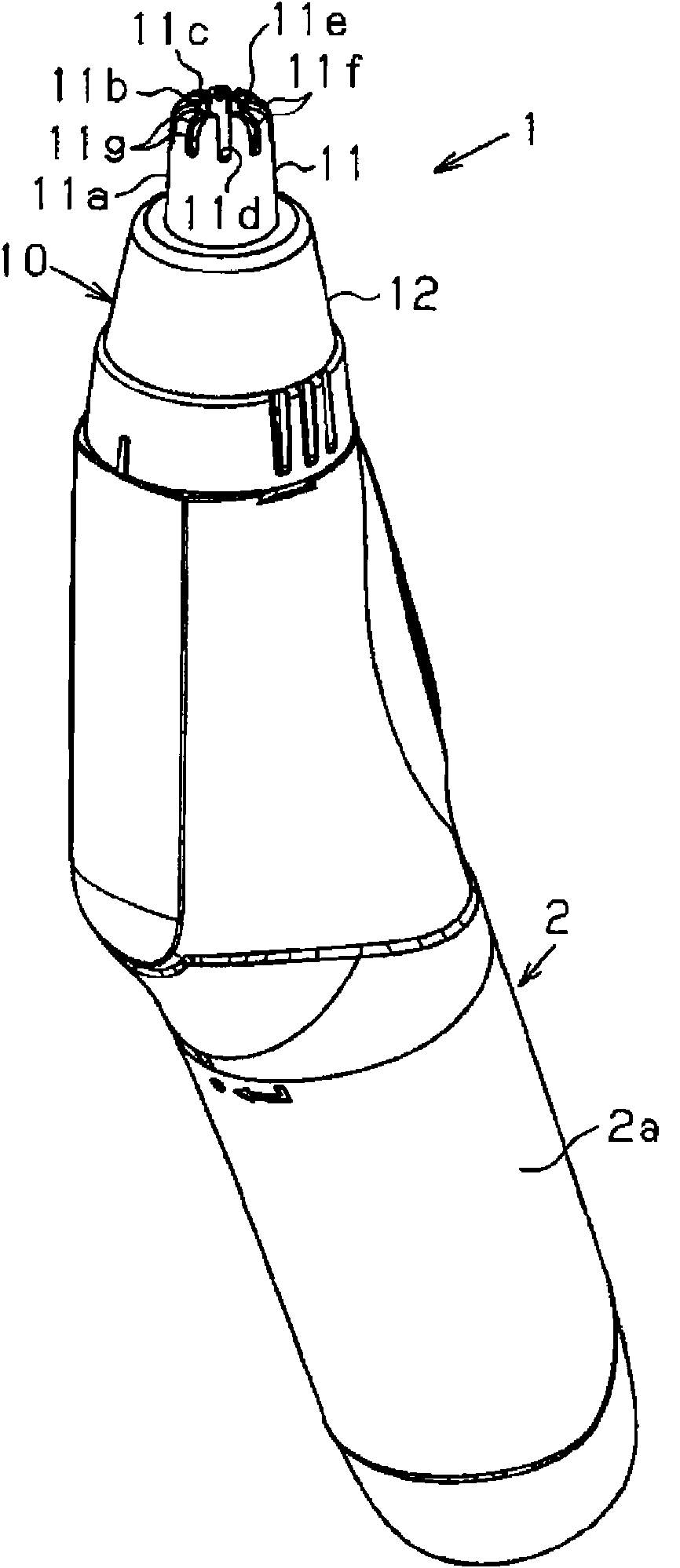

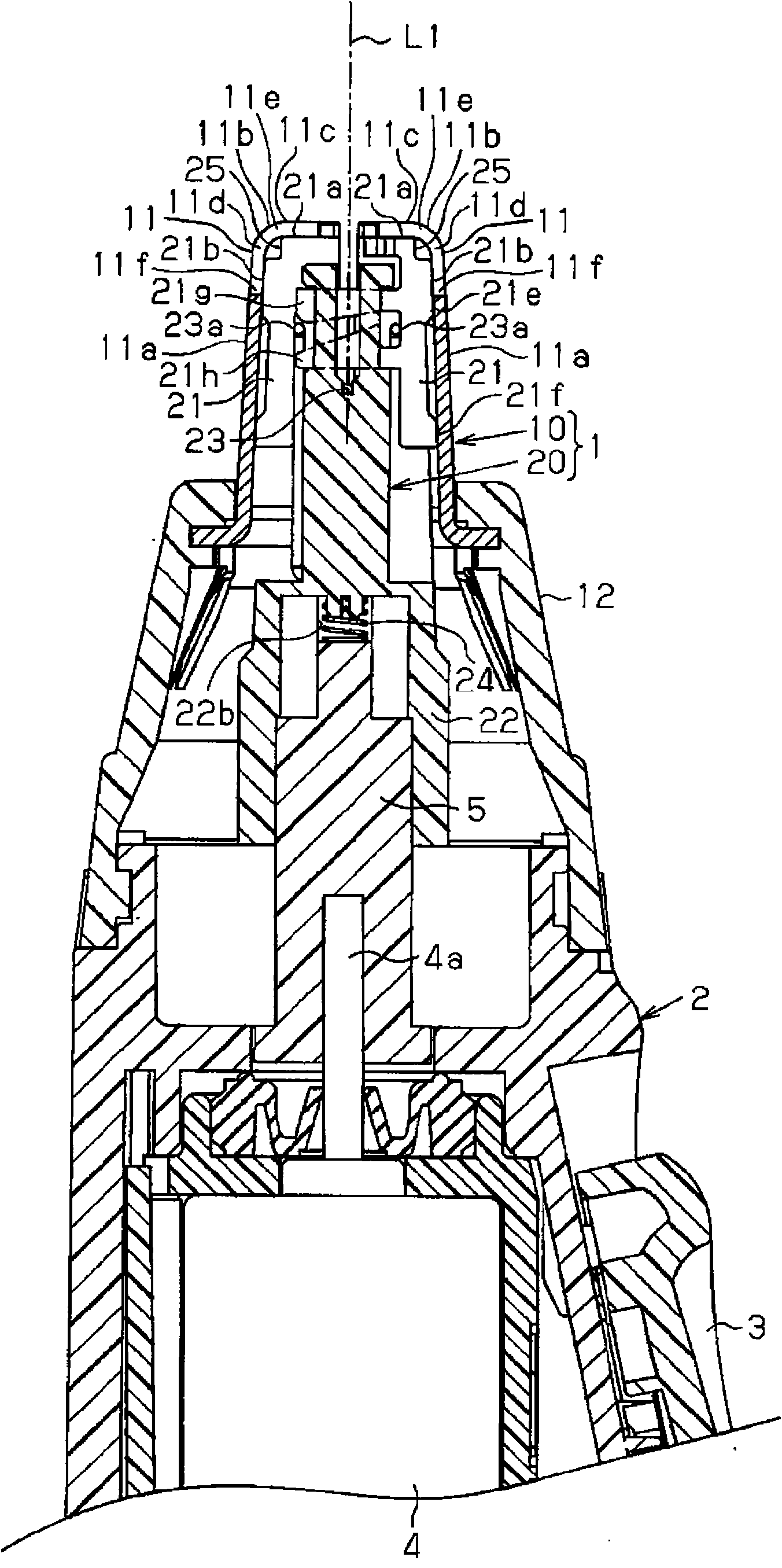

[0021] Figure 1A and 1B A nose hair trimmer is shown used as a hair remover. The overall shape of the nose hair trimmer is cylindrical, and includes a blade unit 1 and a main body 2 connected to the bottom end of the blade unit 1 . Such as image 3 As shown, the blade unit 1 includes an outer blade set 10 and an inner blade set 20 inserted into the outer blade set 10 .

[0022] The main body 2 has a lower portion delimiting a handle 2a. The switch 3 is arranged on the upper side of the handle 2a, and the user operates the switch 3 to turn on or off the nose hair trimmer. The parts of the blade unit 1 and the main body 2 above the handle 2a are inclined with respect to the handle 2a. This shape allows the user to easily insert the outer blade 11 into the nostril while keeping the handle 2a vertical.

[0023] refer to figure 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com