Elevating fountain stage

A stage and fountain technology, applied in the field of performance stage, can solve the problems of lack of performance effects, inability to add water elements, etc., to achieve the effect of enhancing interest and visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

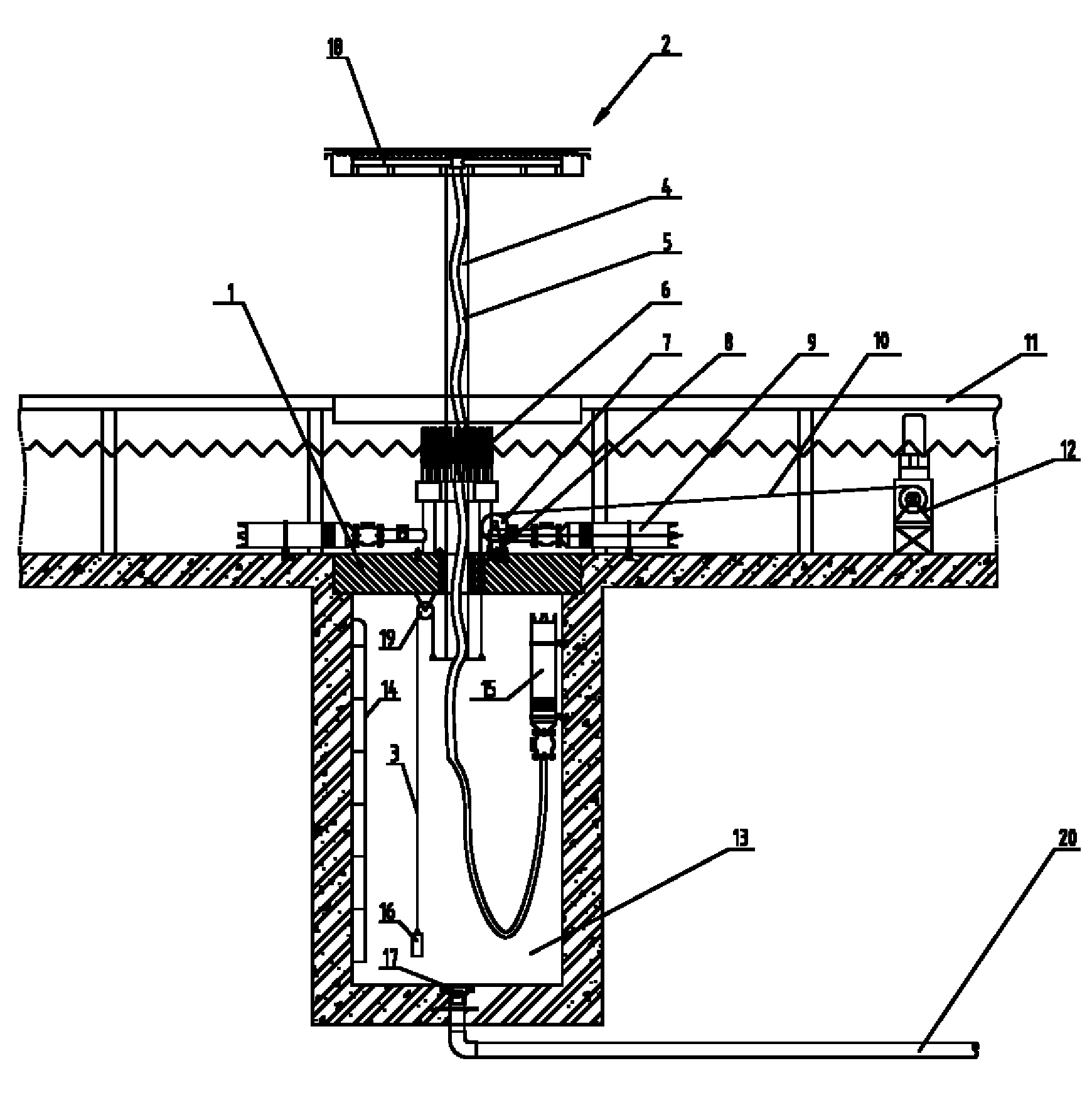

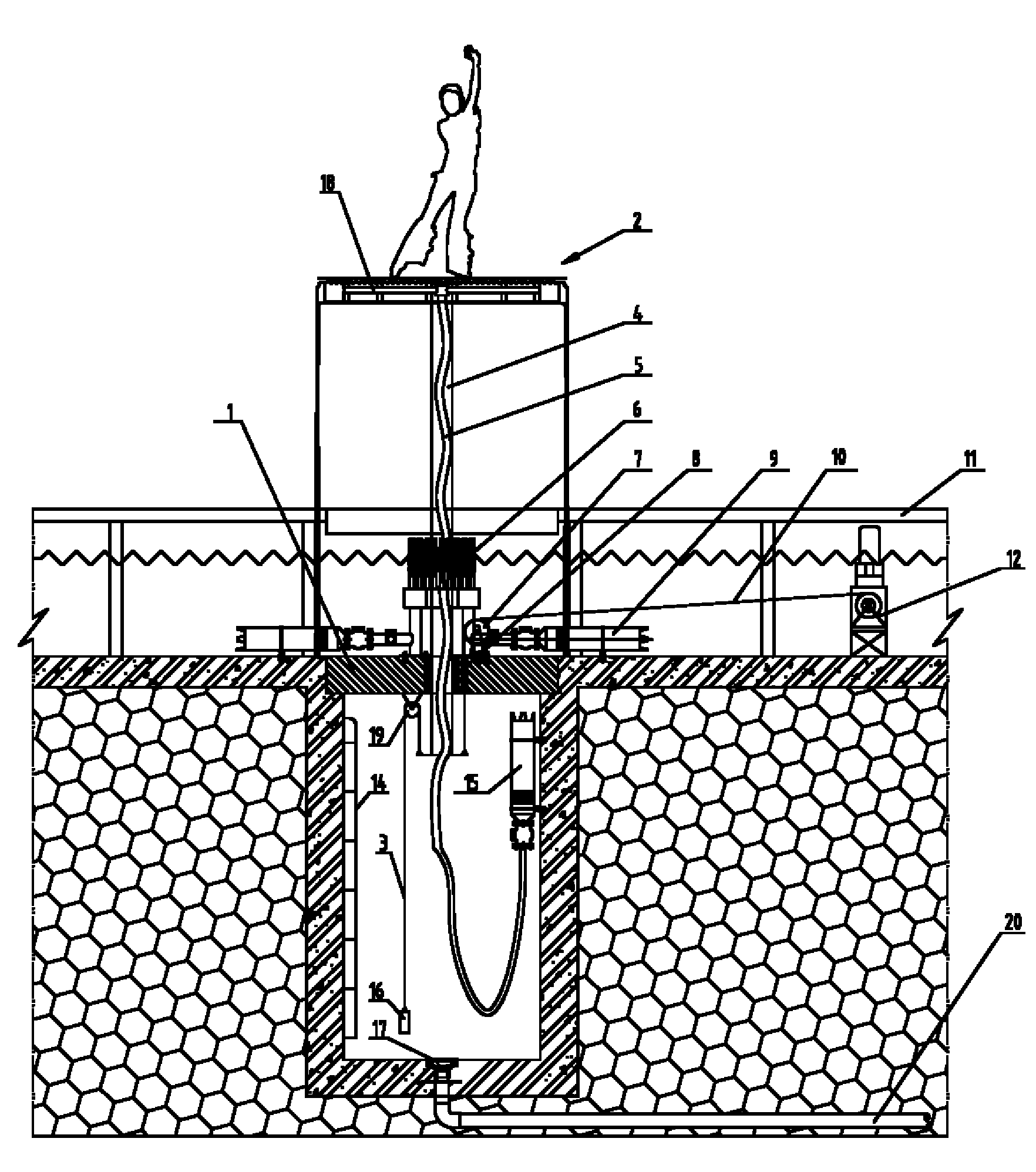

[0017] Such as figure 1 and figure 2 Shown is the first embodiment of a lifting fountain stage according to the present invention, which includes a fixed stage 11, a machine pit 13 arranged under the fixed stage 11, and a support plate 1 arranged in the machine pit 13, and the support plate 1 is provided with a through hole The lifting stage 2 is arranged directly above the support plate 1, and also includes a drive mechanism for driving the lifting stage 2 to move up and down. When the lifting stage 2 descends to the bottom, the lifting stage 2 is the same height as the fixed stage 11, and the lifting stage 2 The lower surface of the lower surface is provided with a hollow guide column 4, and the hollow guide column 4 passes through the through hole, and the interior of the lifting stage 2 is provided with a water flow channel 18; the machine pit 13 is provided with a first water pump 15 and a soft water pipe 5, the One end of the flexible water pipe 5 communicates with the...

Embodiment 2

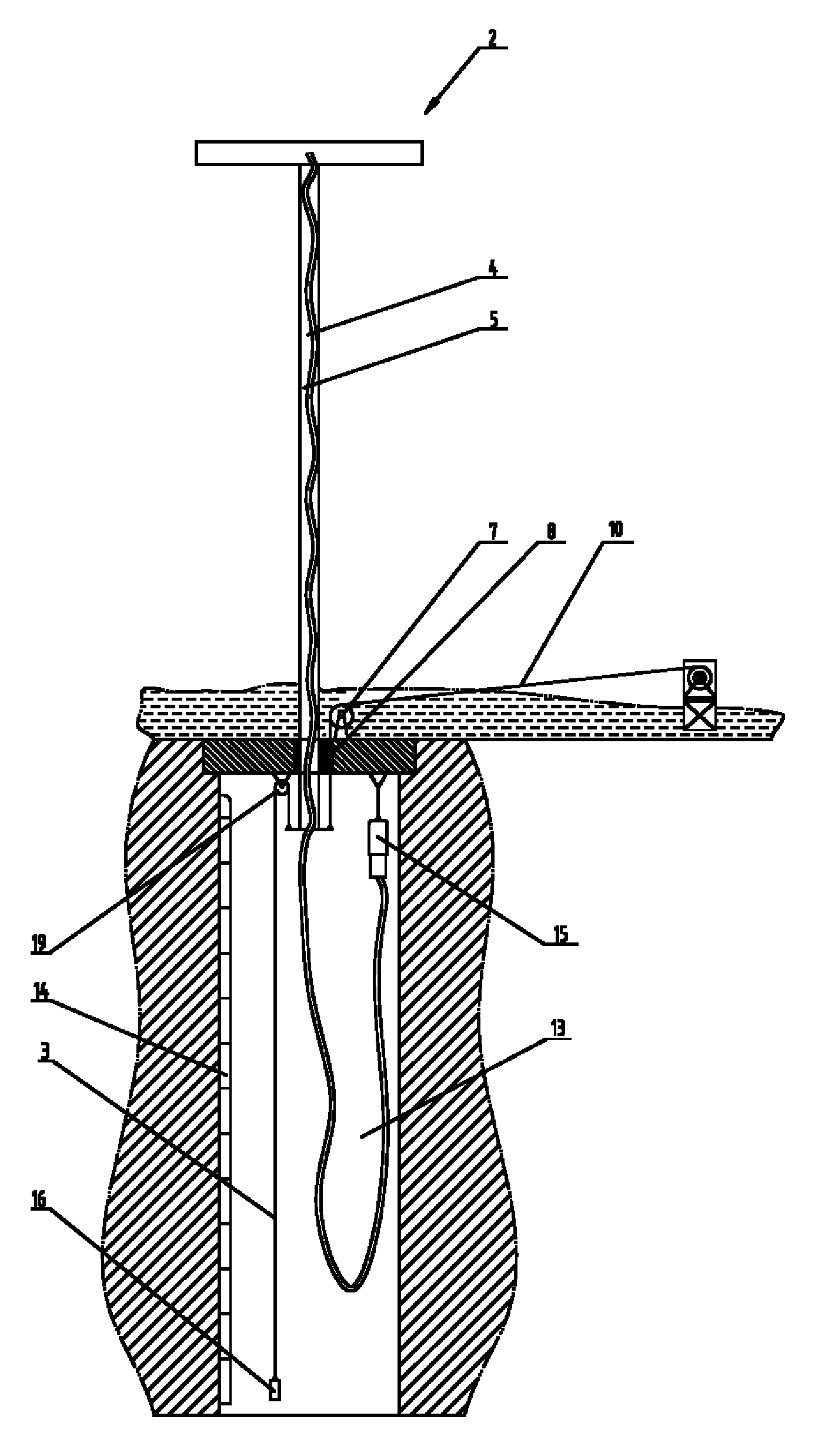

[0025] Such as image 3 Shown is the second embodiment of a lifting fountain stage according to the present invention, which differs from the first embodiment above in that a hook is provided on the lower surface of the support plate 1, and the first water pump 15 is hoisted on the hook by a rope. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com