Labyrinth capsule for drink powder

A beverage powder and labyrinth technology, applied in the field of labyrinth containers, can solve problems such as inability to guarantee powder dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

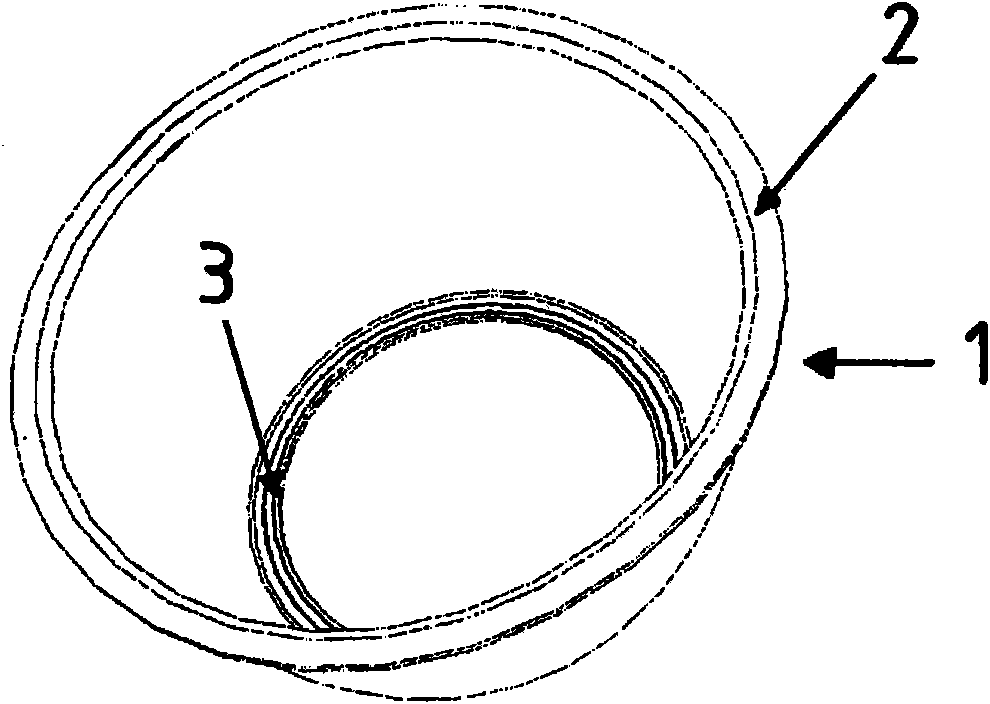

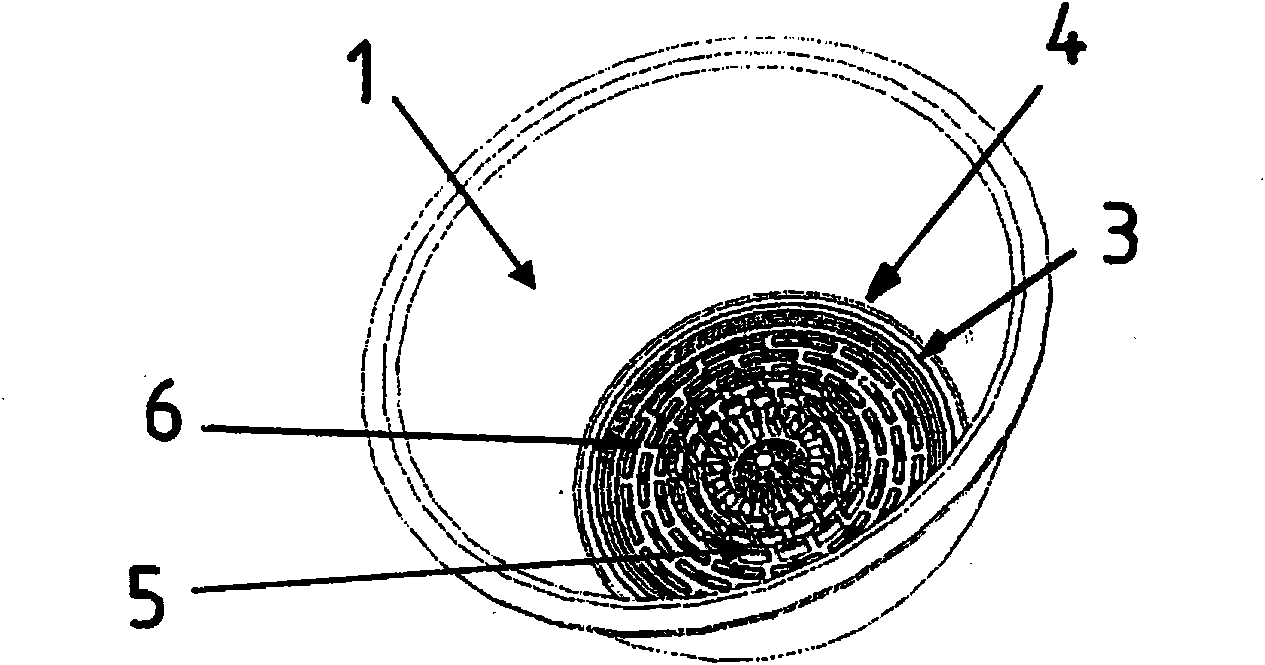

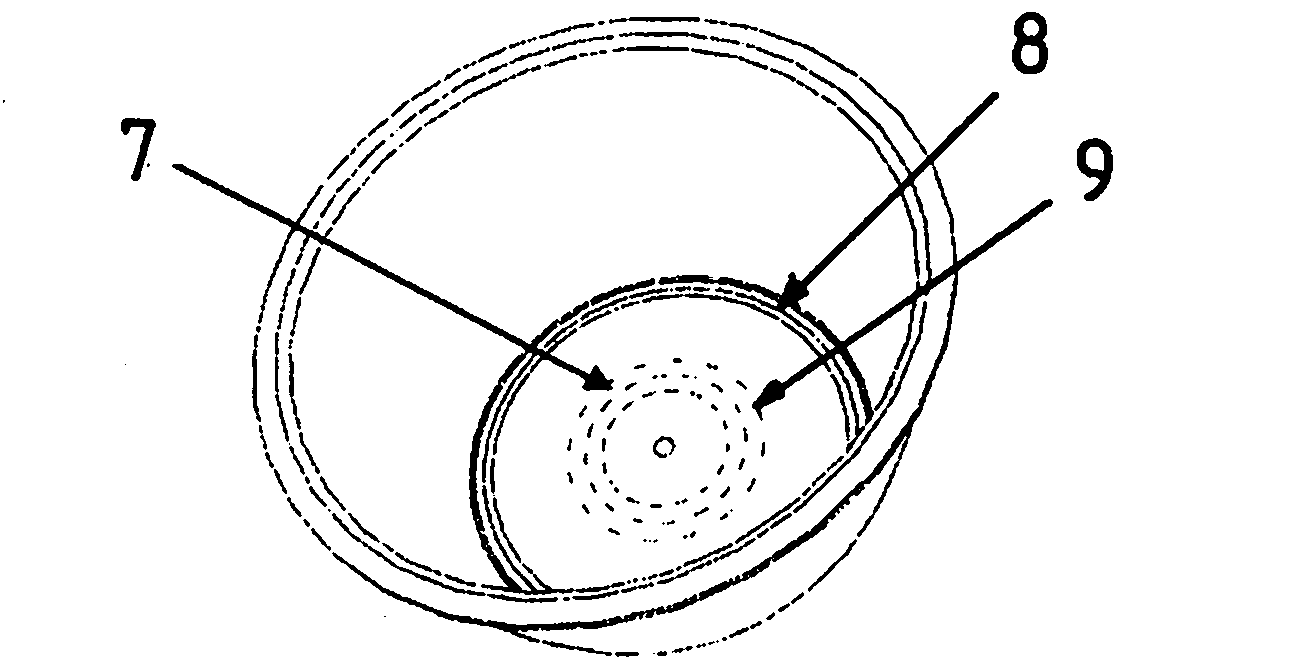

[0017] figure 1 A first component part of a container for beverage powder, for example for coffee or lemon slice powder, is shown, which container consists of four parts in total. Said first component part forms a conical wall 1 of a cup-shaped container comprising a protruding edge 2 on the upper side and an inwardly protruding edge 3 on the lower side. The components are usually thermoformed from laminated plastics having a barrier function which ensure the required gas-tightness. A projection is preferably provided on the protruding edges 2 , 3 in each case to serve as an energy direction sensor ERG for the subsequent welding of the sealing film to the upper edge 2 and the labyrinth plate to the lower edge 3 . When the filling does not need to be air-tight, that is to say absolutely oxygen-tight, the cup can also be made as a one-piece injection molded part together with the cup bottom. Obviously the bottom of the cup is exactly the labyrinth board 4 in this case. In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com