Hollow mechanical mechanism of arc welding robot wrist

A mechanical mechanism and robot technology, which is applied in the direction of manipulators, arc welding equipment, welding equipment, etc., can solve the problems of difficulty in manufacturing cone-worm mechanisms, inconvenient application, and difficulty in ensuring wrist motion accuracy. It is easy to guarantee wrist motion accuracy and process and manufacture Easy, drive kinematic chain simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

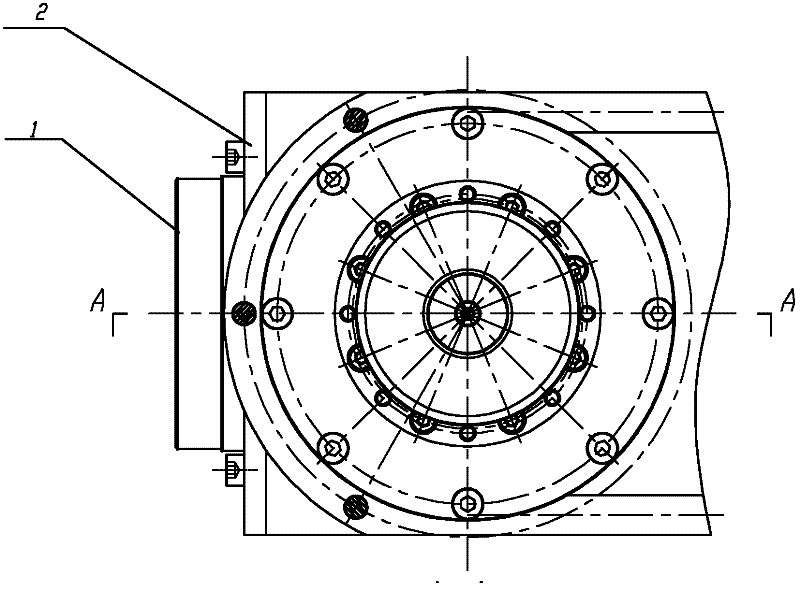

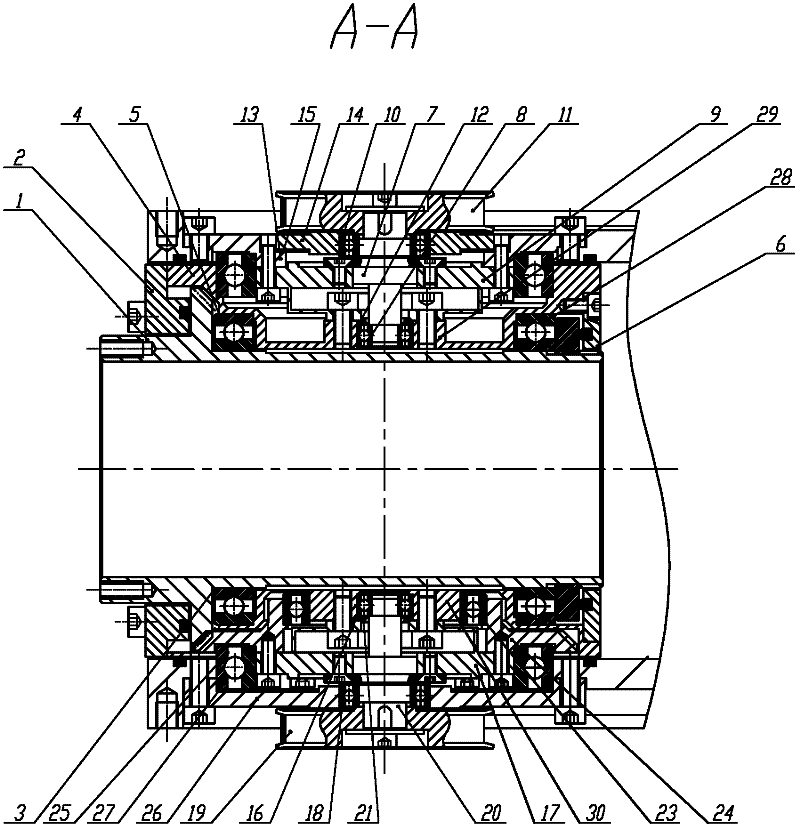

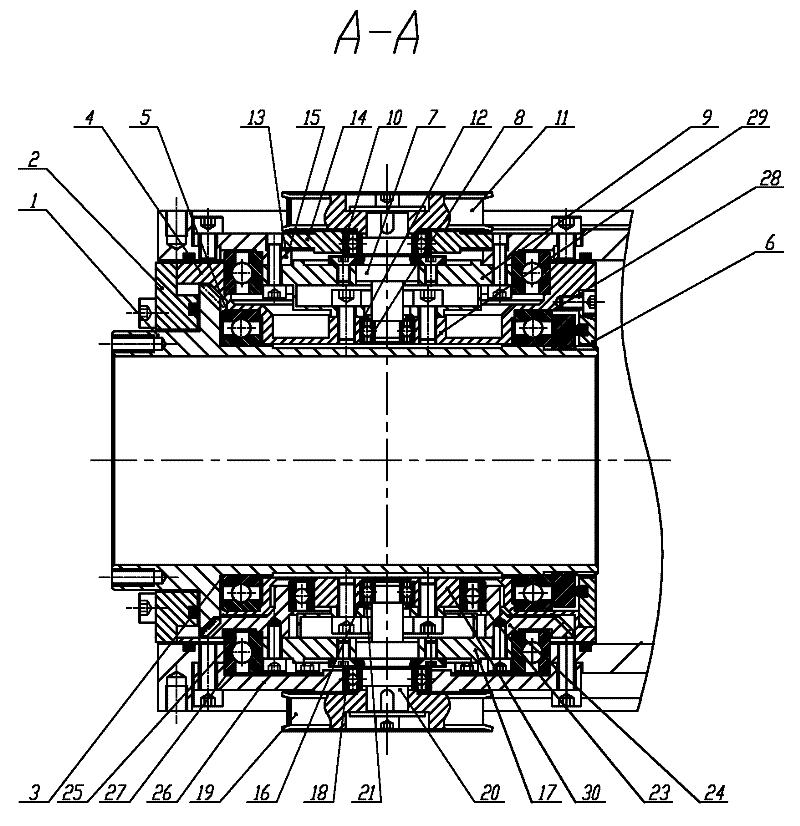

[0009] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the hollow mechanical mechanism of this embodiment includes hollow gear shaft 1, front gland 2, bevel gear adjustment pad 3, axle seat 4, first bearing 5, rear gland 6, wrist swing motion transmission mechanism, hand Rotating motion transmission mechanism and the eighth bearing 28, the wrist swing motion transmission mechanism includes the first small shaft 7, the second bearing 8, the first harmonic reducer 9, the third bearing 10, the first synchronous toothed belt mechanism 11, the first A positioning ring 12, the first gland 13, the second gland 14, the first adjustment pad 15 and the first shaft sleeve 29, the hand rotation motion transmission mechanism includes the fourth bearing 16, the second harmonic reducer 17, the fifth Bearing 18, second synchronous toothed belt mechanism 19, second small shaft 20, second positioning ring 21, sixth bearing 23, bevel gear 24, seventh b...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 Describe this embodiment, the first bearing 5, the second bearing 8, the third bearing 10, the fourth bearing 16, the fifth bearing 18, the sixth bearing 23, the seventh bearing 25 and the eighth bearing 28 in this embodiment are all Ultra-light series bearings can minimize the size of the wrist structure under the premise of ensuring the wrist load. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 The present embodiment will be described. The front end face of the hollow gear shaft 1 of the present embodiment is a common interface end face. This structure is suitable for welding torches of various specifications and has strong versatility. With little or no modification to existing equipment and tools, imported products can be replaced by self-developed robot wrist systems suitable for my country's national conditions, which can reduce costs, facilitate application, and maintain in time.

[0015] Working principle: Connect the welding torch or end effector to the general interface end face of the hollow gear shaft 1. The motion is transmitted to the wrist swing motion transmission mechanism and the hand rotation motion transmission mechanism through the first synchronous toothed belt mechanism and the second synchronous toothed belt mechanism by two servo motors.

[0016] When the motion is wrist swing mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com