Liquid ejection apparatus

A technology of ejecting device and liquid, applied in printing and other directions, can solve the problem of inability to finely adjust the amount of liquid ejected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Next, in order to clarify the contents of the invention of the present application described above, examples will be described in the following order.

[0045] A. Device structure:

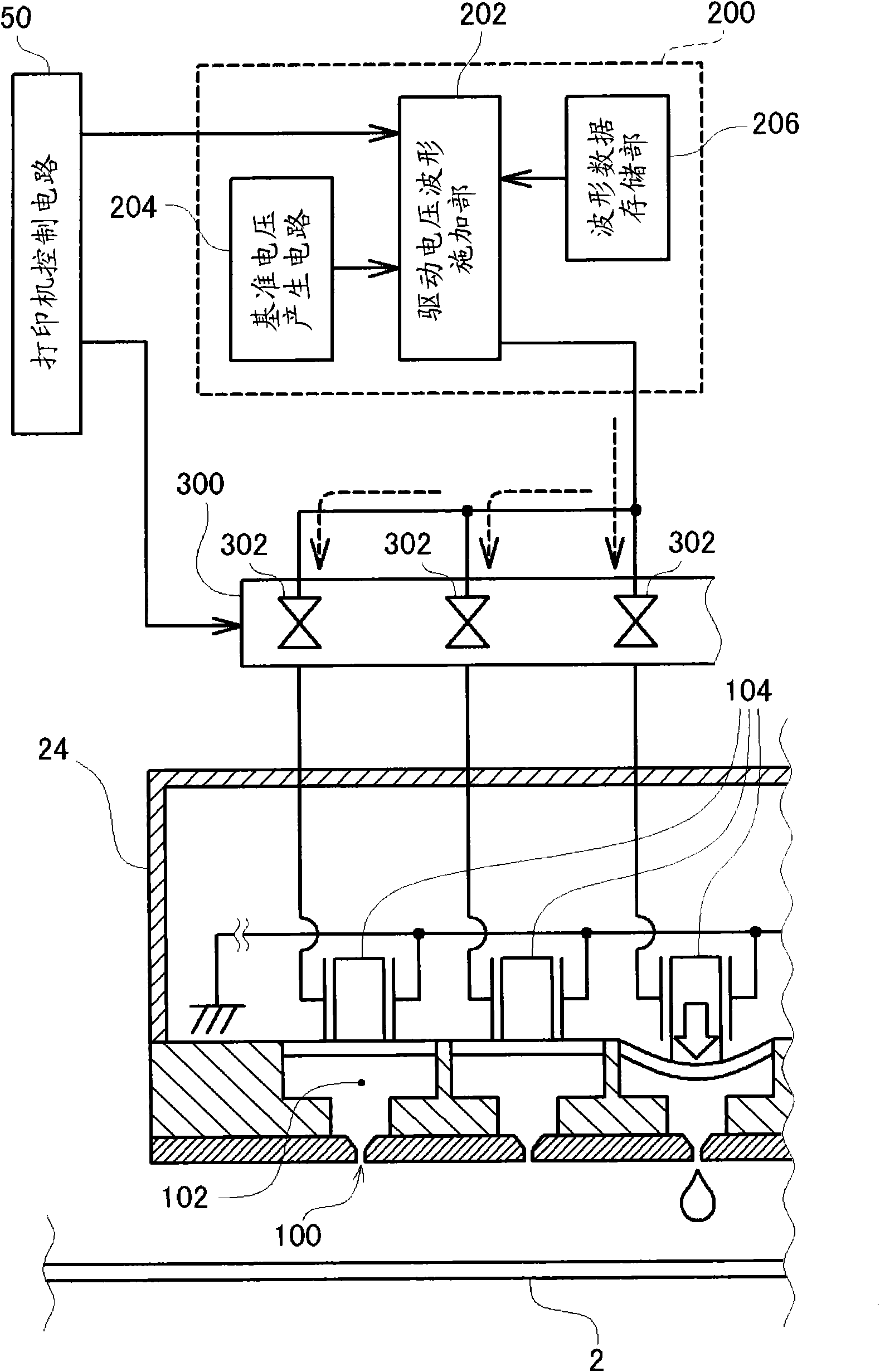

[0046] B. The structure of the spray head:

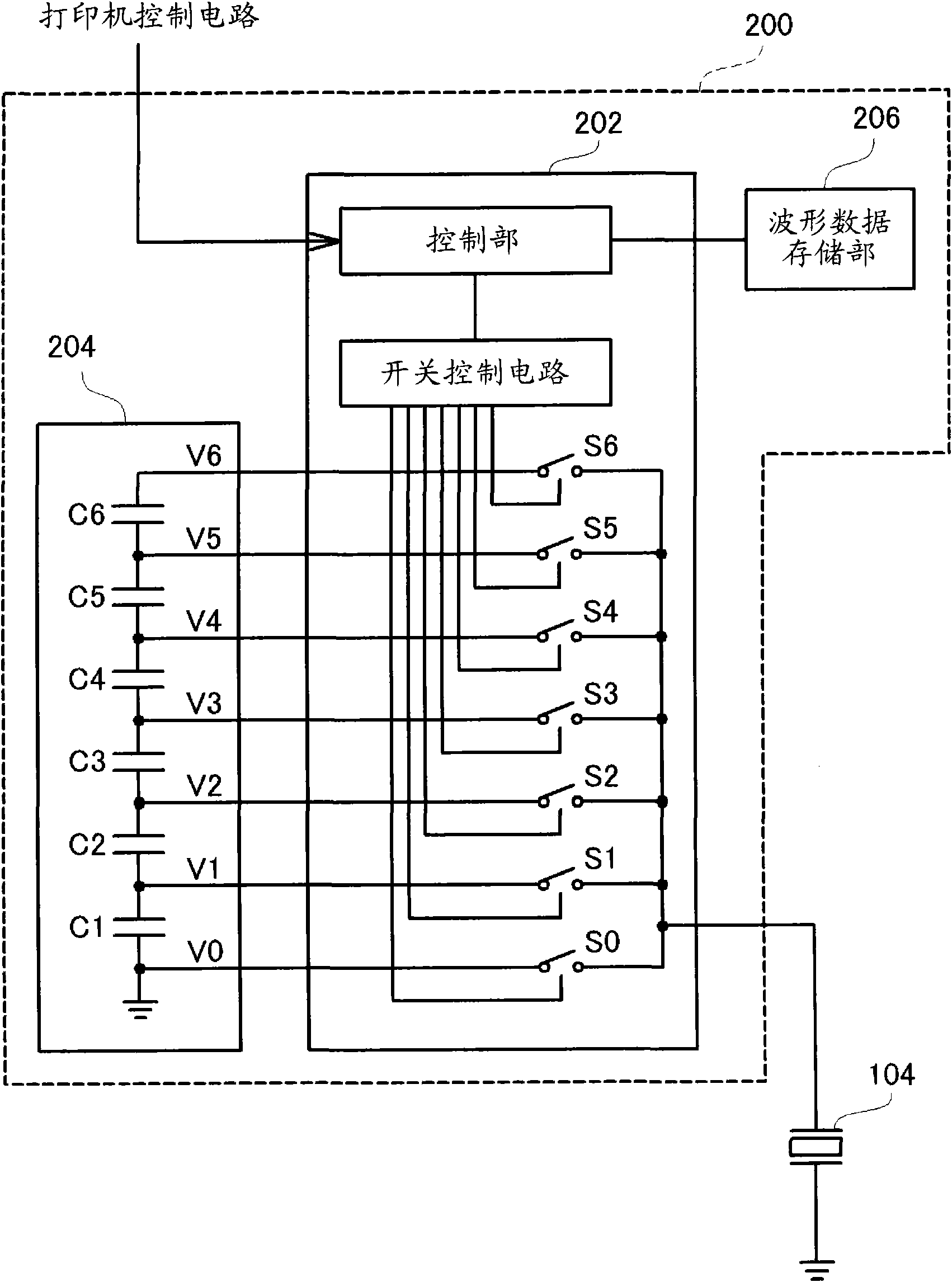

[0047] B-1. Structure of nozzle driving circuit:

[0048] B-2. Generation method of driving voltage waveform:

[0049] C. Adjustment method of injection volume (discharge weight):

[0050] D. Nozzle drive processing:

[0051] E. Variations:

[0052] E-1. The first modified example:

[0053] E-2. The second modified example:

[0054] E-3. The third modified example:

[0055] E-4. Fourth modified example:

[0056] E-5. Fifth modified example:

[0057] A. Device structure:

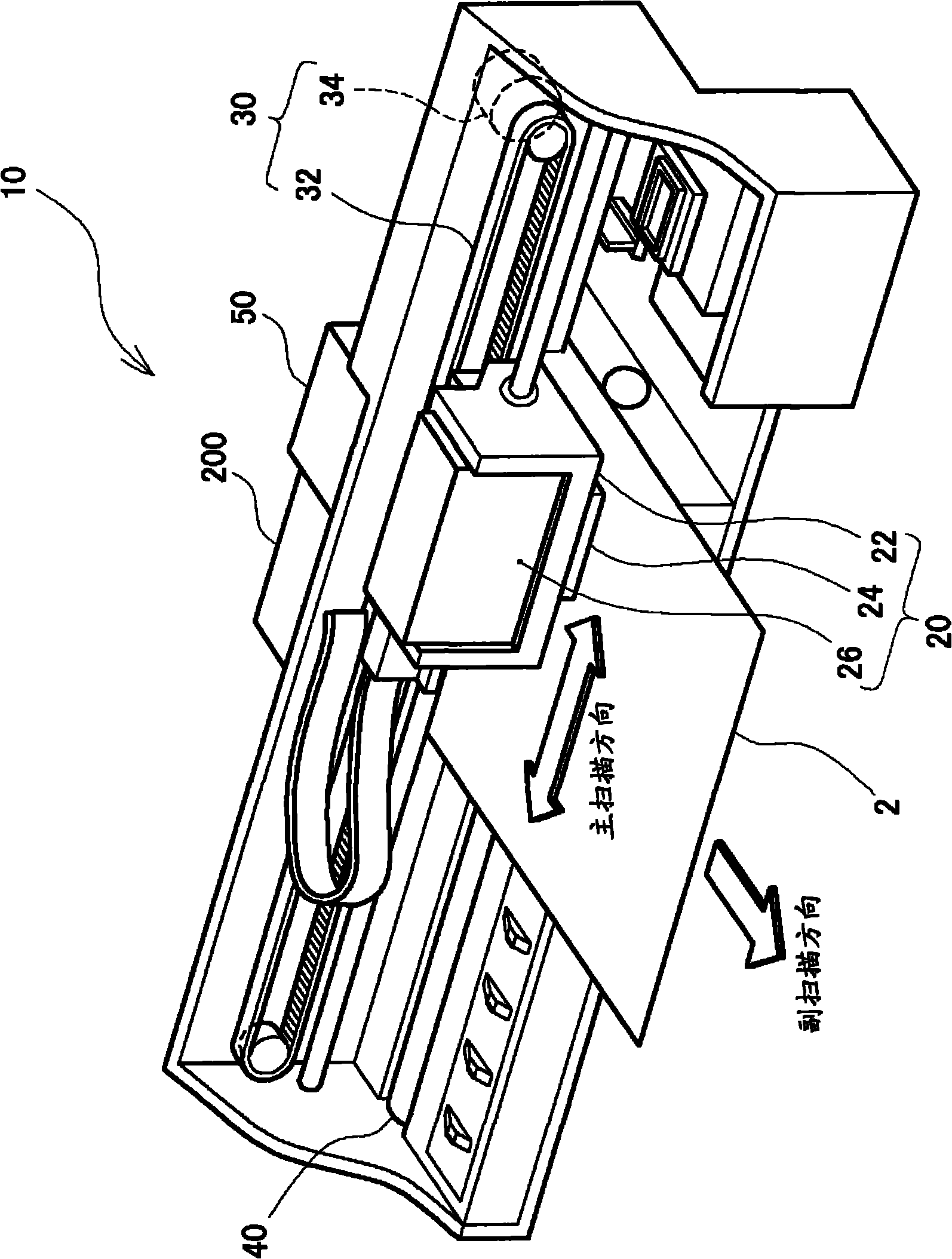

[0058] figure 1 It is an explanatory diagram illustrating an inkjet printer 10 as a liquid ejecting device of this embodiment. The illustrated inkjet printer 10 is composed of a carriage 20 that reciprocates in the main scanning direction and forms ink dots on a prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com