Fuel-injection control method and fuel-injection control device

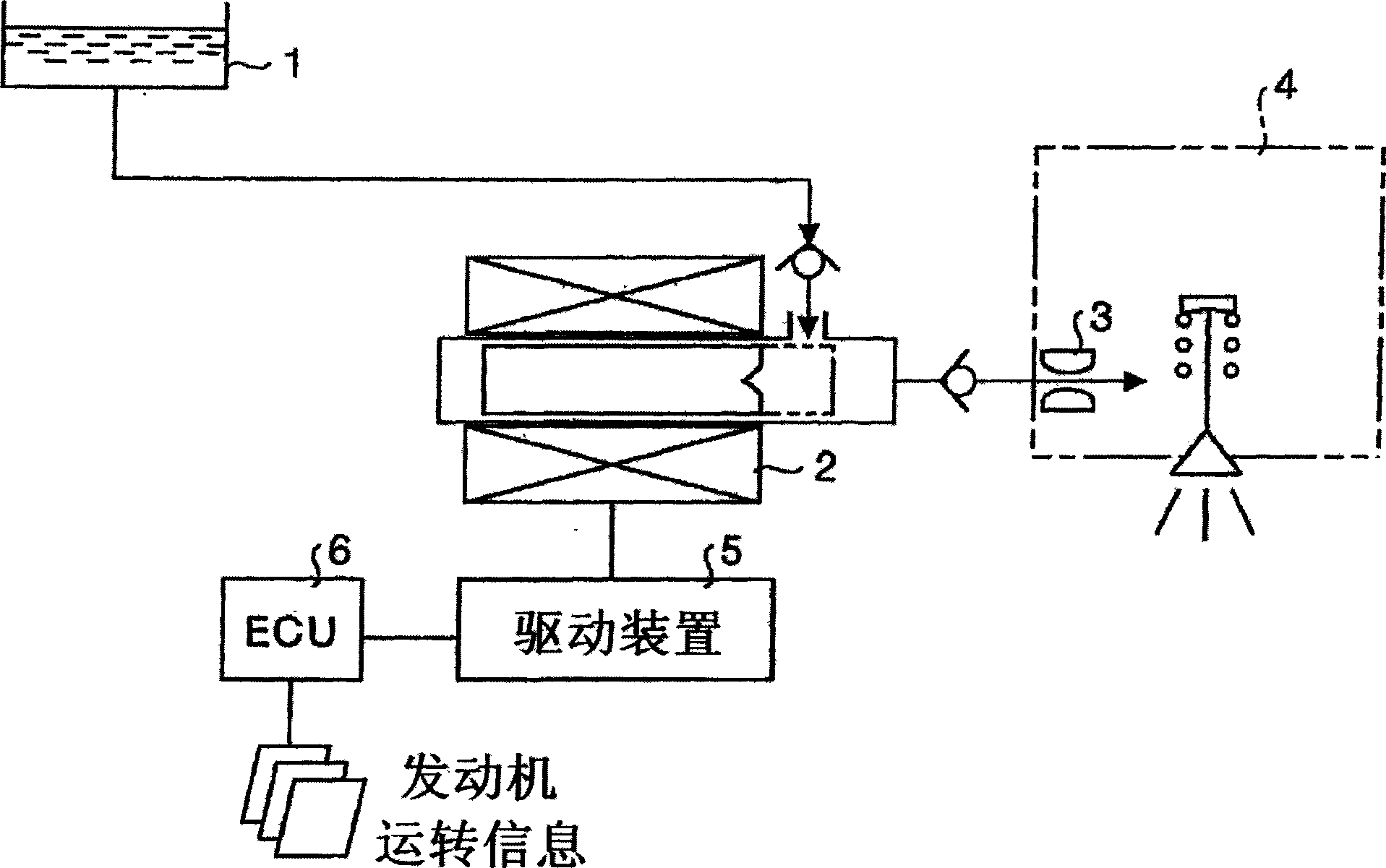

A technology of fuel injection and control method, applied in the directions of fuel injection control, electrical control, engine control, etc., can solve the problem of reduction of fuel storage, difficulty in miniaturization and cost reduction of fuel injection device, and inability to respond to fuel injection demand, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

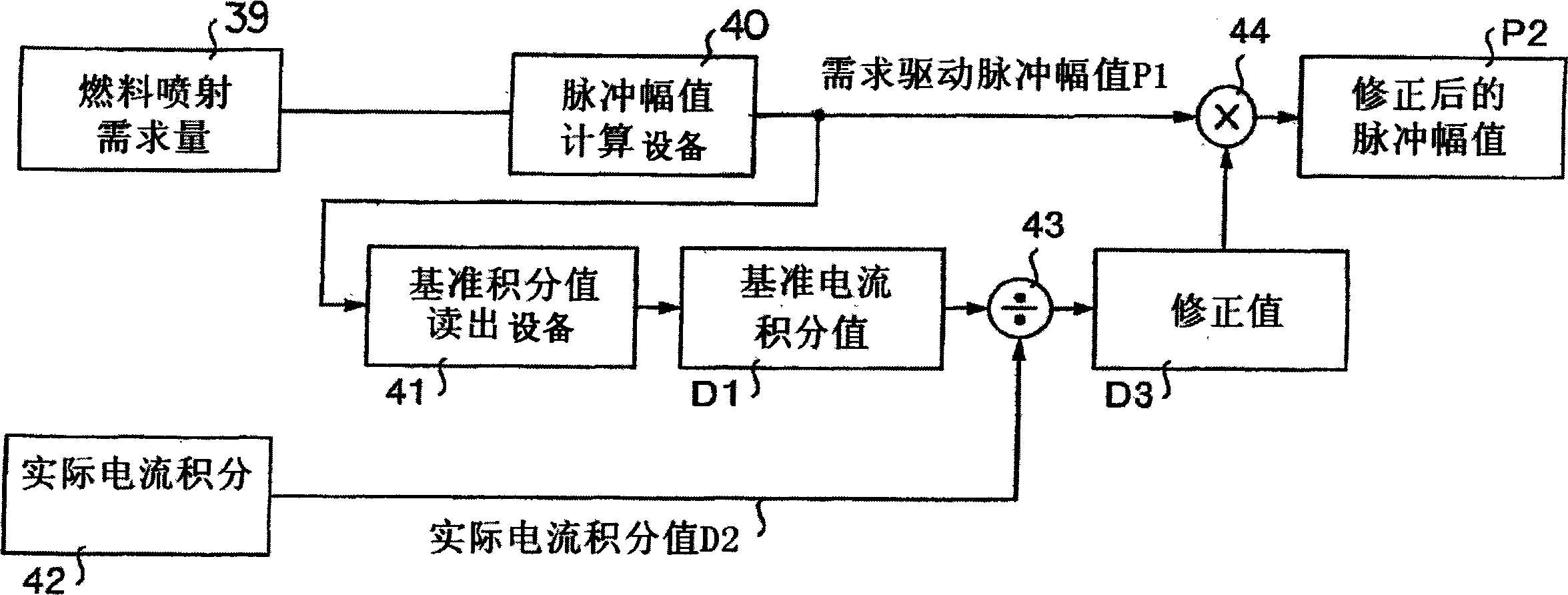

[0053] In the first embodiment of the present invention, the drive pulse current to be output in the next fuel injection cycle is corrected based on the amplitude of the drive pulse output during fuel injection and the actual current integral value after the start of driving the fuel injection solenoid. In this application, the current integral value prestored as data by the present fuel injection control device is referred to as a "reference current integral value", and the detected actual coil current integral value is referred to as an "actual current integral value".

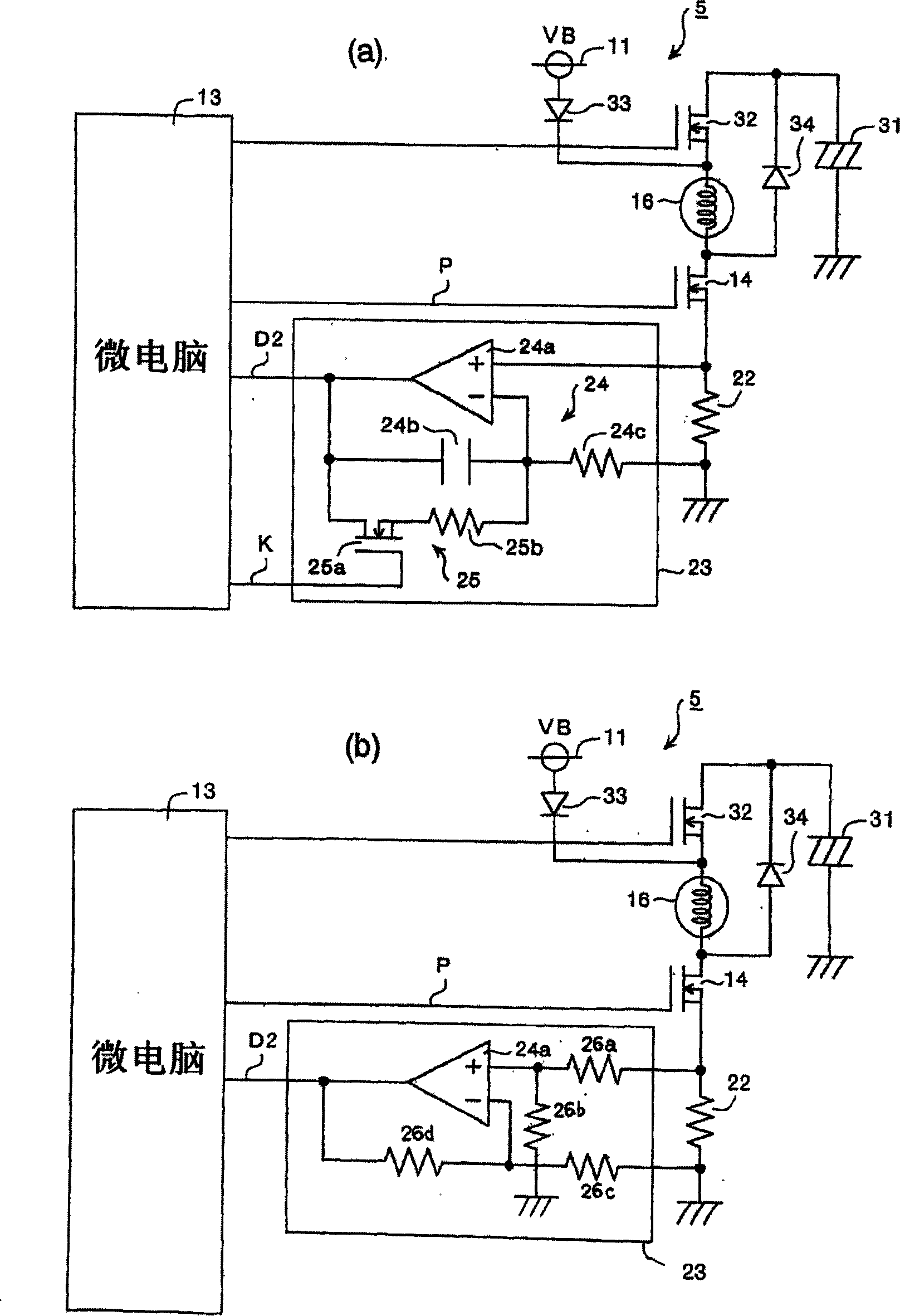

[0054] figure 2 is a specific example of the circuit configuration of the present fuel injection control device.

[0055] exist figure 2 In (a), the solenoid 16 constitutes the electromagnetic fuel injection pump 2 . The drive device 14 for driving this solenoid 16 uses an N-channel FET 14 here. The source of the N-channel FET 14 is connected to the resistor 22 for current detection, and the driving cur...

no. 2 Embodiment approach

[0095] In the second embodiment, the actual current integral value of the coil current flowing through the solenoid is compared with the target current integral value preset for the fuel injection demand amount, and based on the comparison between the actual current integral value and the target current integral value As a result, the magnitude of the drive pulse of the solenoid is corrected, and the solenoid is driven and controlled.

[0096] Therefore, in the second embodiment, the object to be compared with the actual current integral value is replaced by the "reference current integral value preset for the drive pulse amplitude corresponding to the fuel injection demand amount" in the above-mentioned first embodiment. is "the preset target current integral value relative to the fuel injection demand".

[0097] Figure 12 It is a block diagram showing a functional configuration for realizing the fuel injection control method and device according to the second embodiment. ...

no. 3 Embodiment approach

[0104] In the third embodiment, the estimated fuel injection amount corresponding to the actual current integral value of the coil current flowing through the solenoid is compared with the required fuel injection amount, and based on the comparison result of the estimated fuel injection amount and the above-mentioned required fuel injection amount , correct the driving pulse amplitude of the solenoid, and drive and control the solenoid according to the corrected driving pulse amplitude.

[0105] In this third embodiment, the above-mentioned figure 2 (a) or (b) shown in the control circuit. Here, feedback control is performed for correction value calculation, and feedback control is performed to converge the estimated injection flow rate to the target injection amount based on the estimated injection flow rate obtained from the actual current integral value.

[0106] Figure 14 It is a block diagram showing the functional configuration of the fuel injection method and appara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com