Method for plating gold on equilong connecting fingers

A gold finger and finger technology, which is applied in the field of gold plating of equal-length gold fingers, can solve problems such as residue, non-retention, hidden dangers in the reliability of gold fingers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

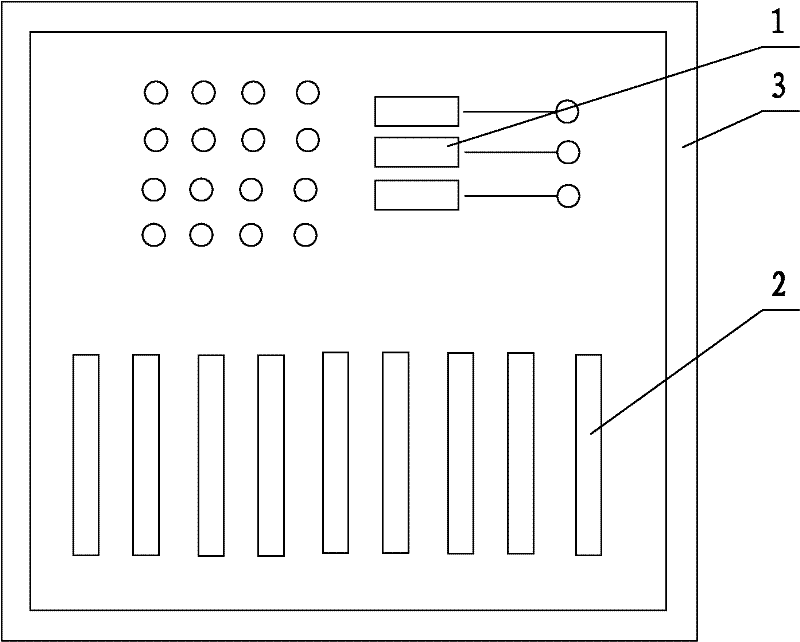

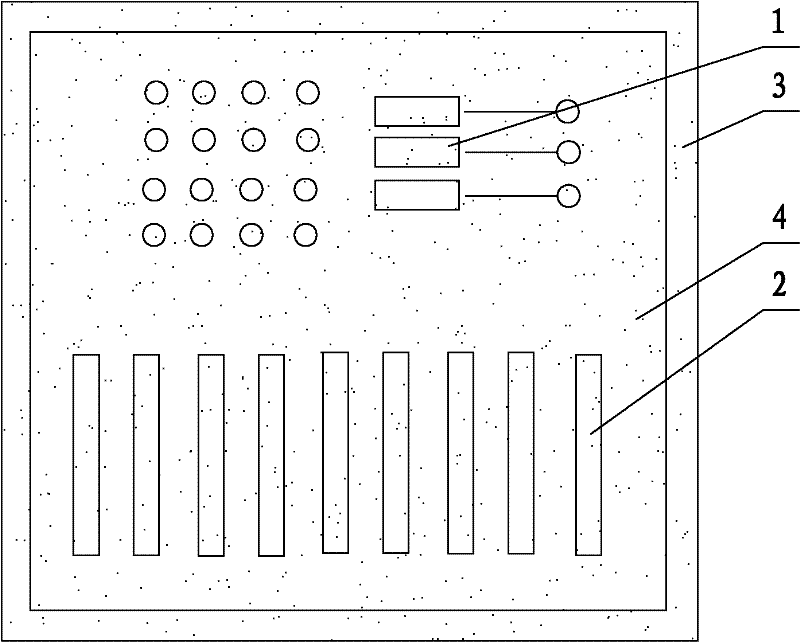

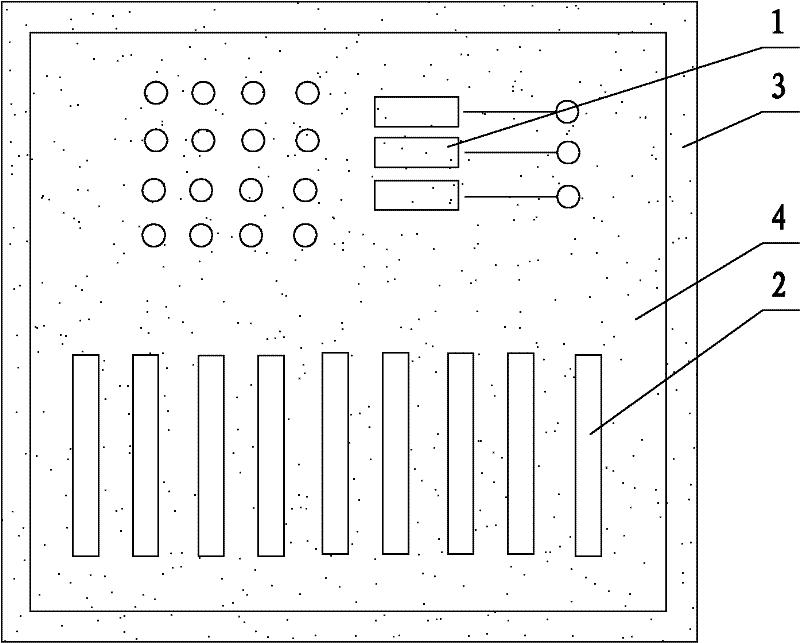

[0027] As an example of the gold-plating method of the equal-length gold finger of the present invention, such as Figure 1 to Figure 8 ,include:

[0028] (1) Make in-board graphics 1 and equal-length golden finger 2 graphics on the surface of the PCB board;

[0029] (2) A copper layer 4 with a thickness of 0.3μm~0.8μm is deposited on the entire PCB board;

[0030] (3) Paste anti-plating tape 5 on the non-gold-plated area;

[0031] (4) Use micro-etching method to remove the immersion copper layer on the gold finger;

[0032] (5) Use the remaining copper immersion layer 4 as a gold-plated wire to gold-plat the equal-length gold fingers 2;

[0033] (6) Use solder mask micro-etching method to remove the remaining copper immersion layer 4;

[0034] (7)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com