Method for plating gold on equilong connecting fingers

A technology of gold fingers and fingers, which is applied in the field of gold plating of equal-length gold fingers, can solve problems such as residue, non-retention, exposed copper at the end of gold fingers, etc., and achieve the effects of low cost, high efficiency, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

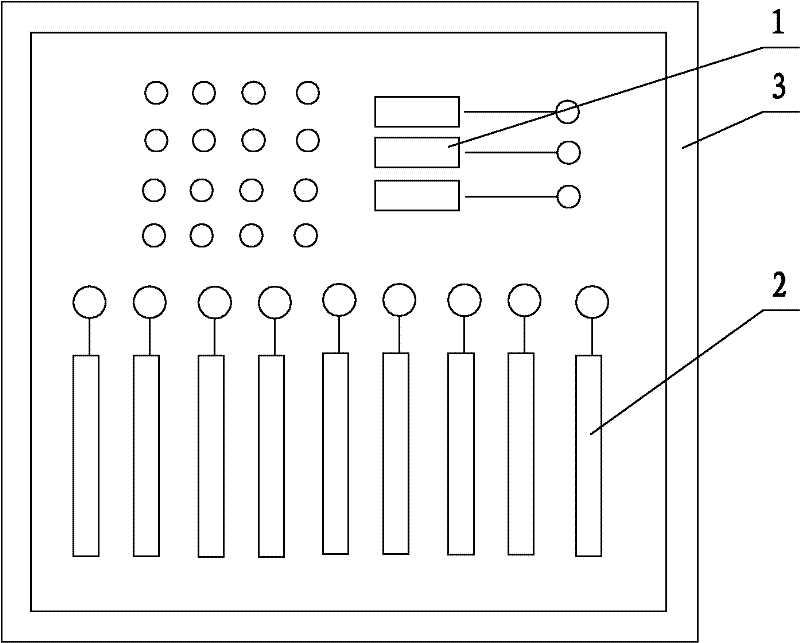

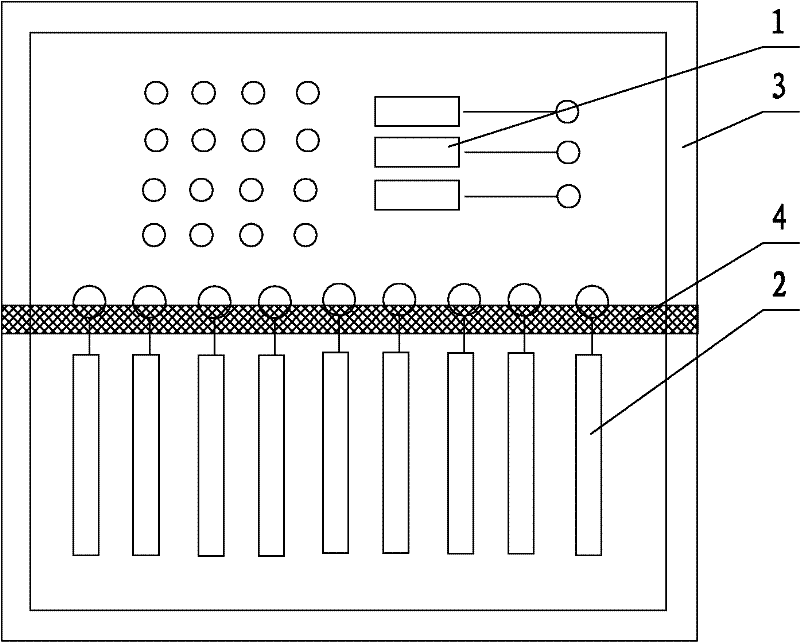

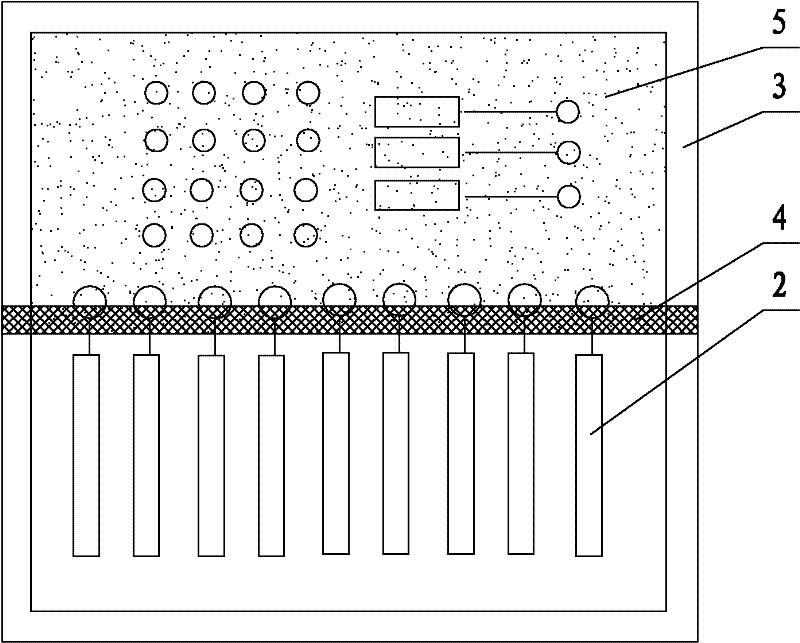

[0029] As the embodiment of the gold-plated method of equal-length golden finger of the present invention, as Figure 1 to Figure 7 include:

[0030] (1) Prepare the PCB board, and make the in-board graphic 1, conductive auxiliary edge 3 and equal-length gold finger 2 graphics on the PCB. The conductive auxiliary edge 3 and equal-length gold finger 2 are separated from each other, and the equal-length gold finger 2 passes through The leads are connected to the pattern 1 on the board, and a connection area is formed at all leads;

[0031] (2) screen printing conductive ink 4, the conductive ink 4 in the screen printing area covers the connection area between the equal-length gold finger 2 and the graphic 1 in the board, so that all the lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com