LED lamp module with light distribution on internal surface

A technology for LED lamps and inner surfaces, which is applied to semiconductor devices, light sources, electric light sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

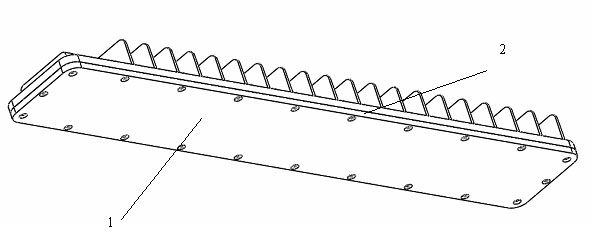

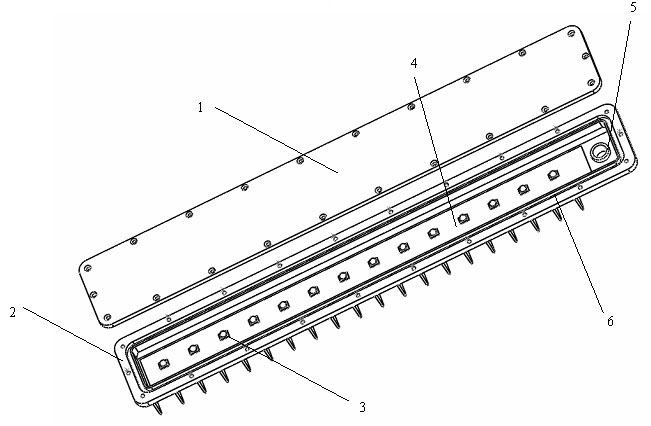

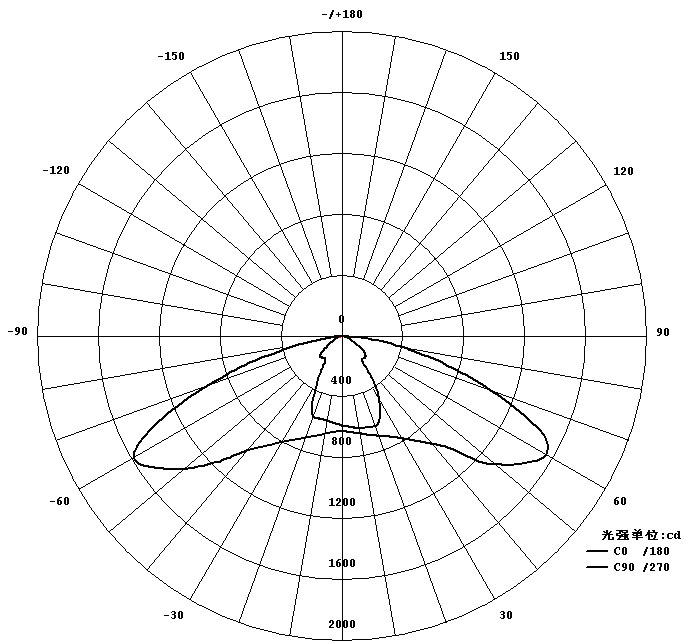

[0030] Such as figure 1 and as figure 2 As shown, an LED lamp module with light distribution on the inner surface is composed of an inner surface light distribution lens 1 , an aluminum alloy casing 2 , an LED light source 3 , a PCB board 4 , a waterproof joint 5 , and a waterproof rubber ring 6 . The LED light source 3 is welded on the PCB board 4, the PCB board 4 and the waterproof joint 5 are fixed on the aluminum alloy casing 2, the inner curved surface light distribution lens 1 presses the waterproof rubber ring 6 on the aluminum alloy casing 2, and the aluminum alloy casing 2 Radiating fins are distributed on the outer surface. The light distribution unit of the inner curved surface light distribution lens 1 is set on the LED light source 3, and the two together form a functional lighting unit. Such as Figure 4-Figure 7 As shown, the inner curved surface light distribution lens 1 is composed of a light distribution unit array located on the inner side and an outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com