Heat radiation structure and projector thereof

A technology of heat dissipation structure and projector, applied in cooling/ventilation/heating transformation, optics, instruments, etc., can solve problems such as increasing manufacturing cost, controlling design complexity, and easy overheating and damage of electronic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

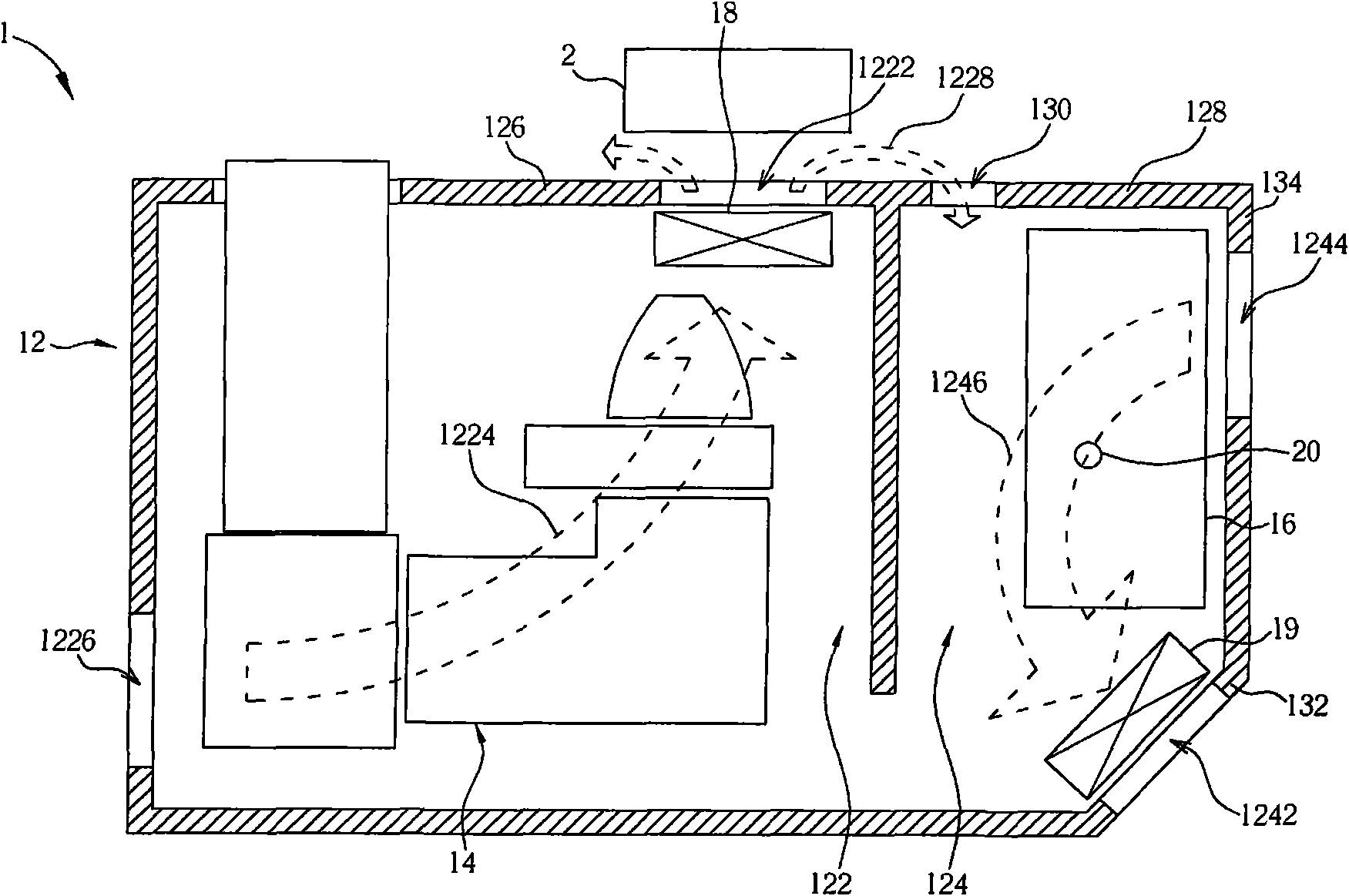

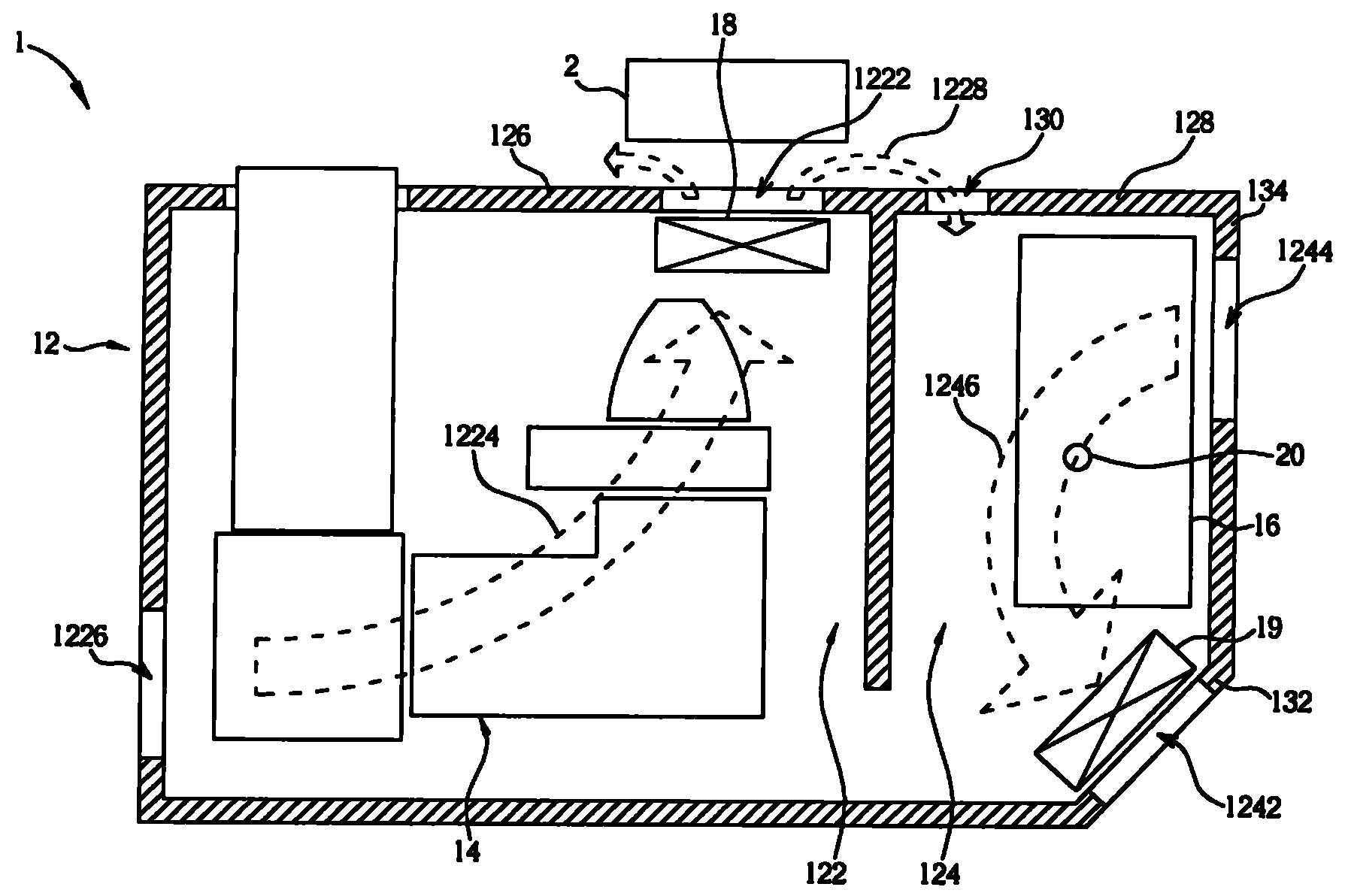

[0019] see figure 1 , which is a schematic diagram of the projector 1 according to the first embodiment of the present invention. The projector 1 includes a casing 12 , an optical engine 14 (optical engine), and a lamp 16 . The casing 12 has substantially independent first heat dissipation space 122 and second heat dissipation space 124 therein. The casing 12 includes a first side wall 126 and a second side wall 128 adjacent to the first side wall 126. The first air outlet 1222 forms The through hole 130 is formed on the second side wall 128 adjacent to the first air outlet 1222 and communicates with the second heat dissipation space 124 on the first side wall 126 and communicates with the first heat dissipation space 122 . The first heat dissipation airflow 1224 (indicated by a dotted hollow arrow) can flow through the first heat dissipation space 122 and flow out of the housing 12 from the first airflow outlet 1222 .

[0020] In practice, the casing 12 usually has a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com