Four-cylinder cross pile hole-making machine

A technology of cross piles and hole forming machines, which can be applied to earth movers/excavators, construction, etc., and can solve problems such as limited development and technical complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

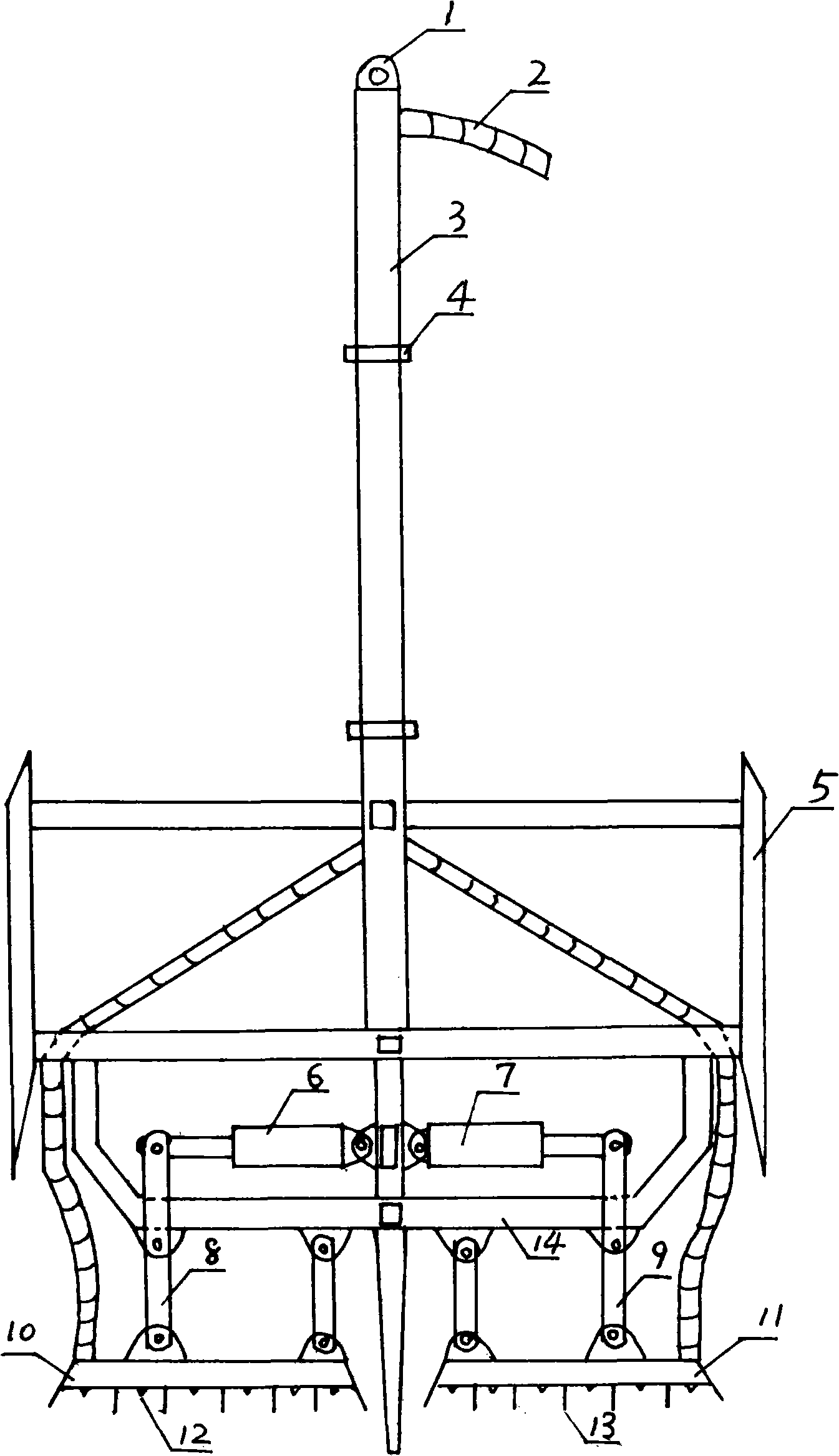

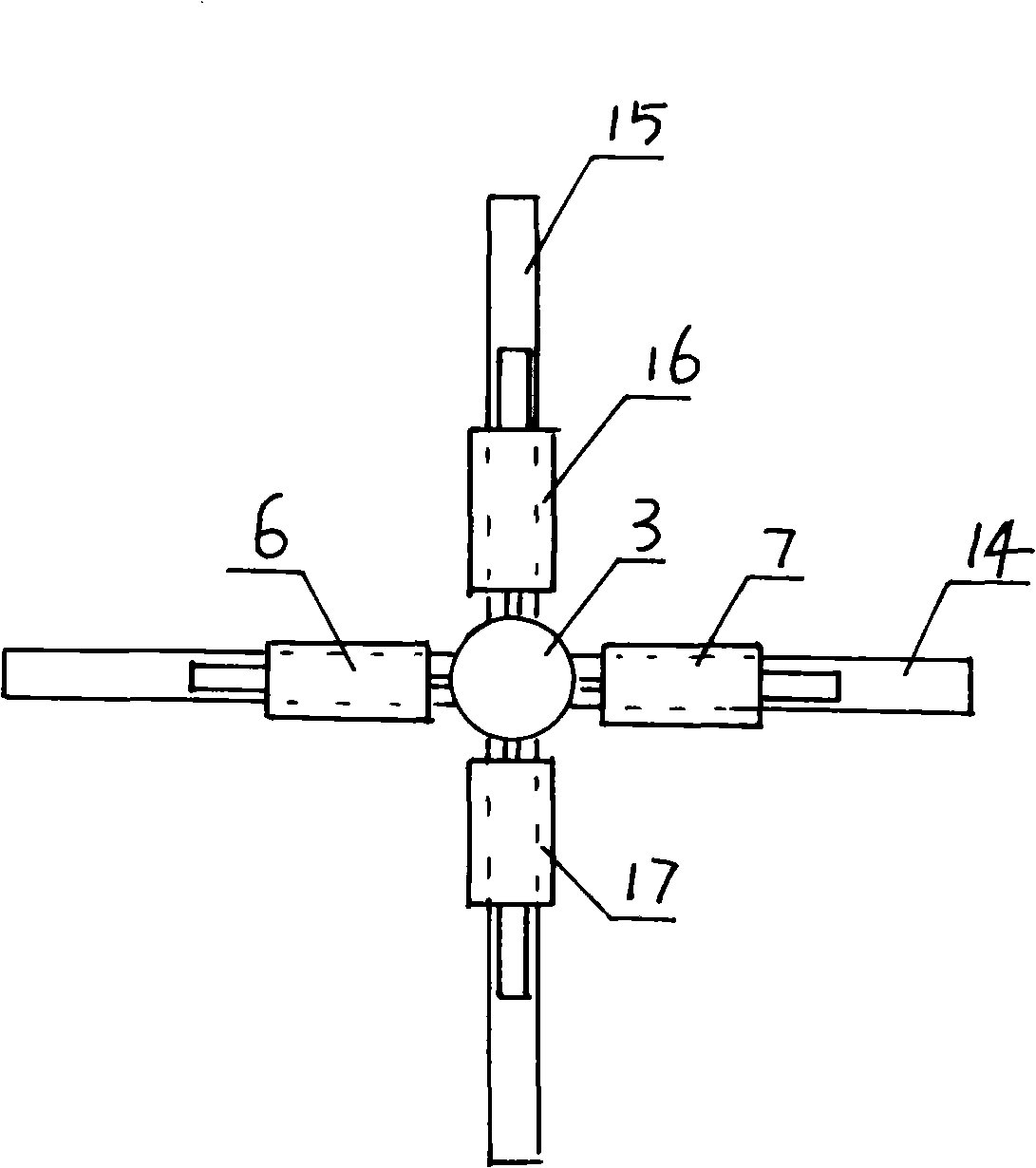

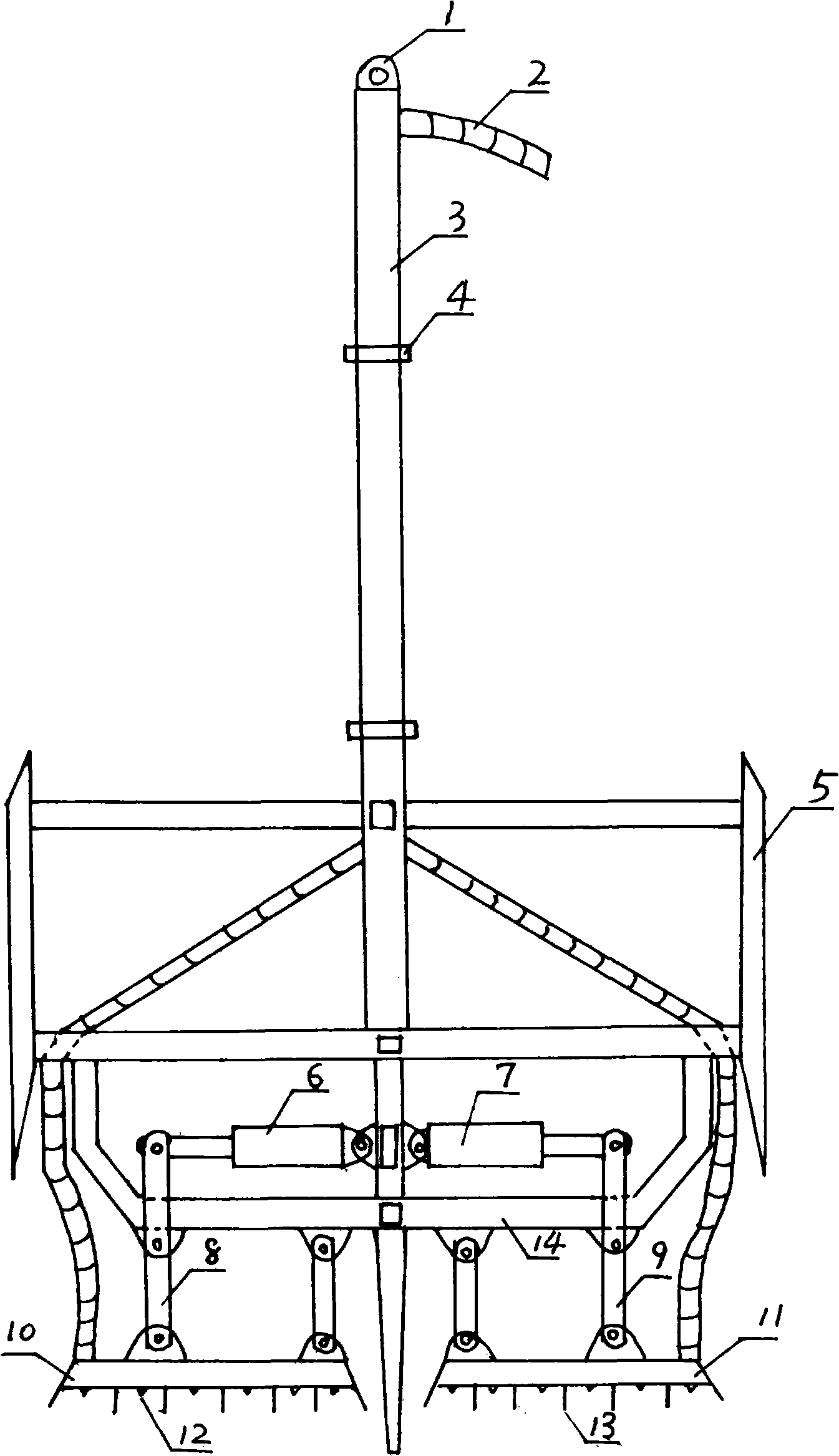

[0010] The accompanying drawing is a specific embodiment of the present invention, which includes a lifting ring 1, a water inlet rubber hose 2, a water inlet steel pipe 3, a quick connector 4, four limit plates 5, front, rear, left, and right, and the left end of the left oil cylinder 6 is pinned. On the upper end of the left rocker arm 8, the left rocker arm 8 is pinned to the left cutter bar 10, and the middle pin is connected to the beam A14; the right end of the right oil cylinder 7 is pinned to the upper end of the right rocker arm, and the lower end of the right rocker arm is pinned to the right Knife bar 11, middle pin is connected to crossbeam A14; Front oil cylinder 16 rear oil cylinder 1 and the front and rear rocker arm front and back knife bars that it connects, and saw blade is all equal to left and right.

[0011] The present invention needs to be used in conjunction with the frame during use. The frame is equipped with a hydraulic oil pump and an automatic contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com