Stepping motor driving device and driving method

A stepper motor, rotor position technology, applied in the direction of motor generator control, electrical components, control systems, etc., can solve problems such as power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the stepping motor driving device and driving method according to the present invention will be described below with reference to the drawings.

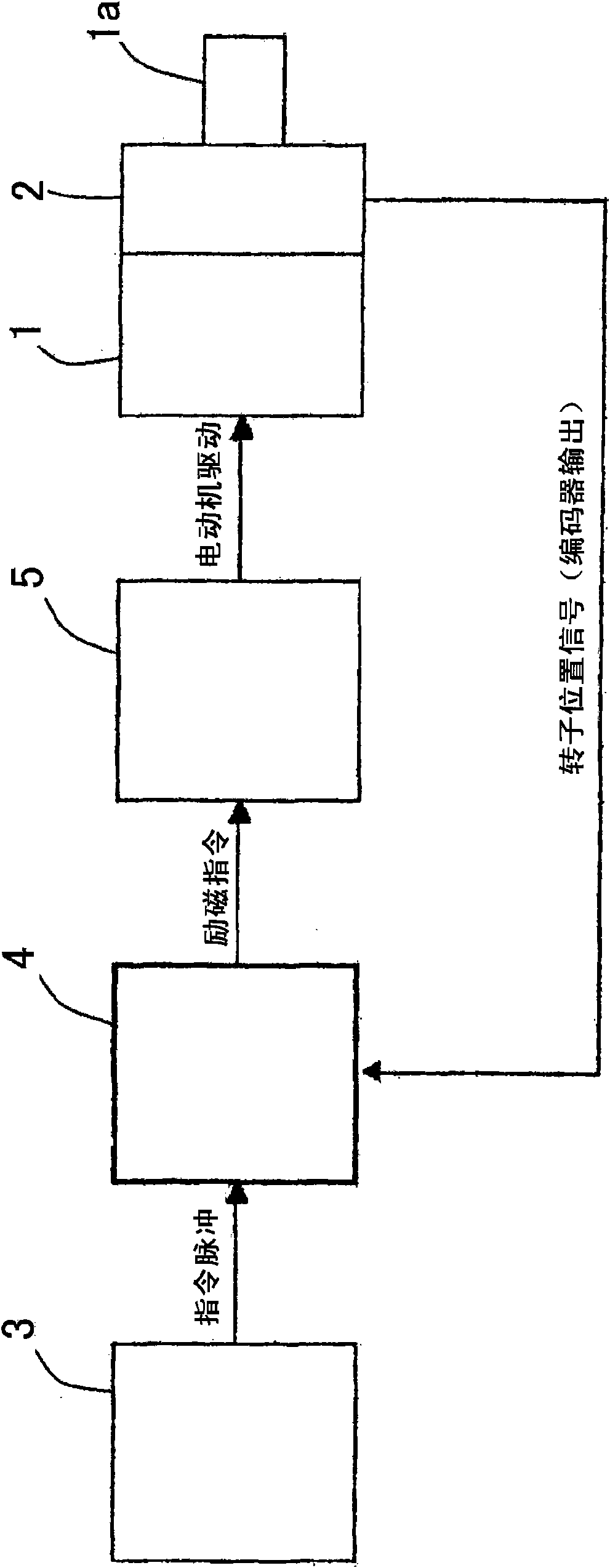

[0040] figure 1 A block diagram showing the structure of a stepping motor drive unit.

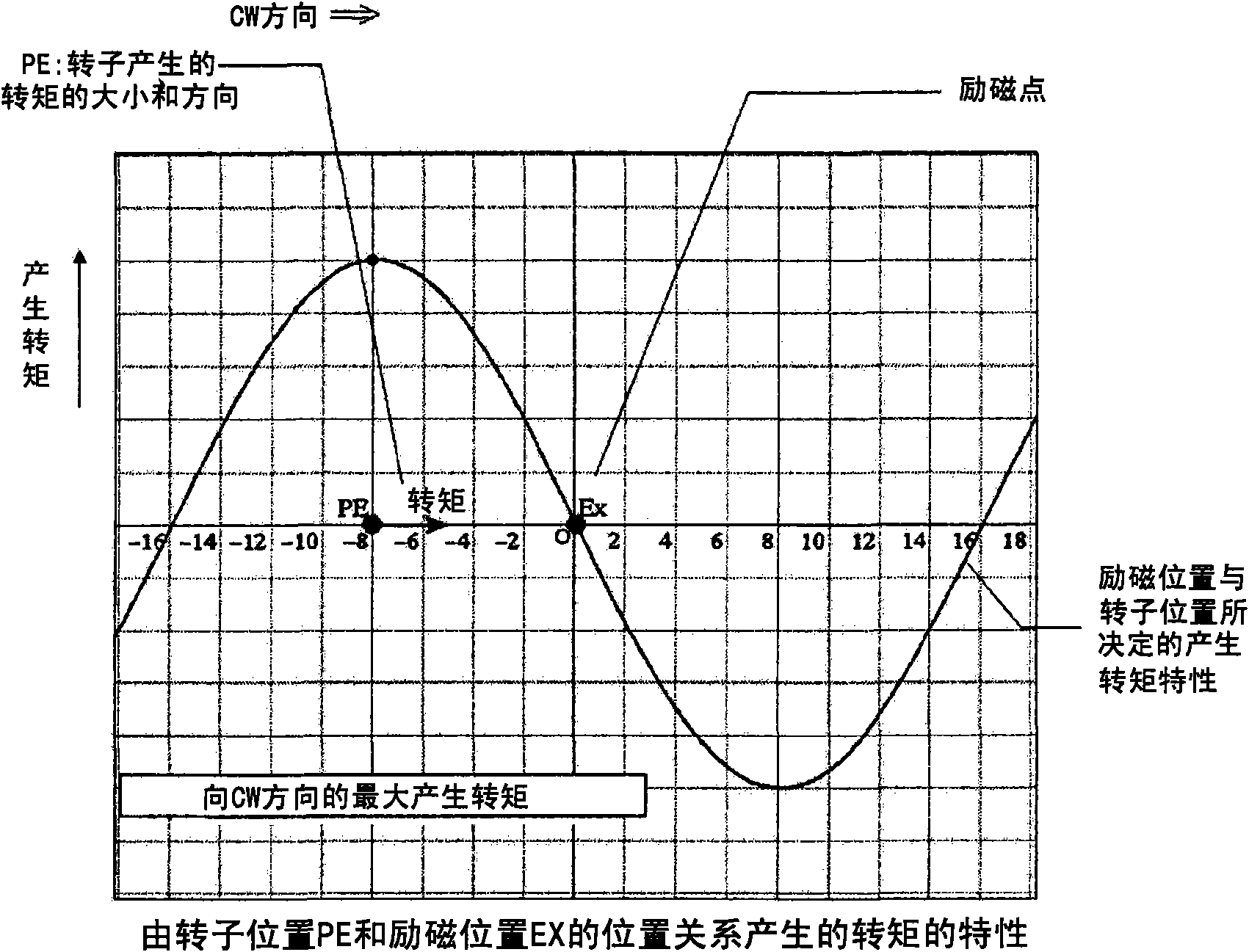

[0041] The stepping motor drive device performs torque control by shifting the excitation stable point of the stepping motor 1 in the clockwise or counterclockwise direction relative to the actual rotor position, without controlling using the motor current value.

[0042] The encoder 2 (rotor position detection unit) is provided on the output shaft 1 a of the stepping motor 1 , and detects the rotor position using an output pulse corresponding to the rotation amount of the stepping motor 1 .

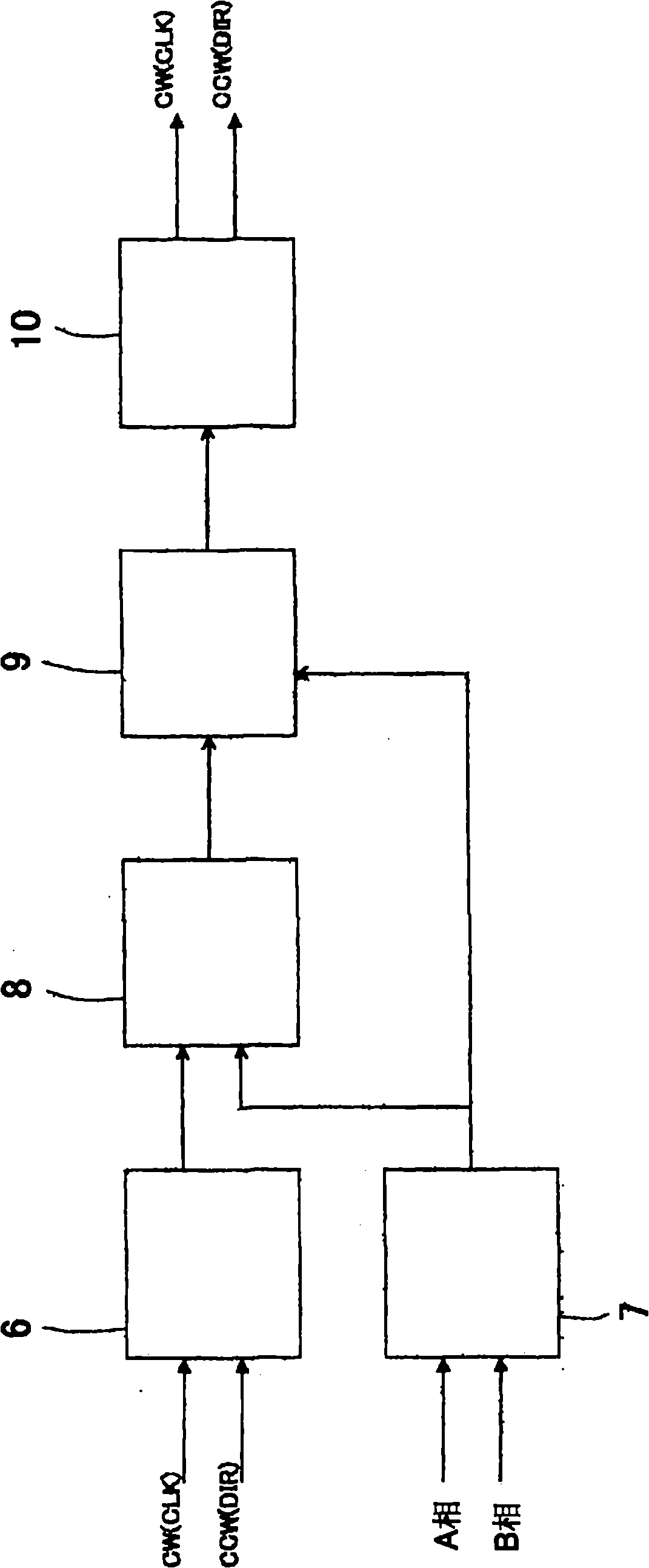

[0043] The controller 3 outputs a position command serving as a drive command for the stepping motor 1 . The position command is a rotation command signal composed of CW direction (clockwise) pulse / CCW (counterclockwise) pulse, DIR (r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com