Liquid volume metering device

A measuring device and technology of liquid volume, applied in the field of liquid volume measuring device, can solve the problems of difficult to achieve internal management goals of enterprises, tank deformation, unstable foundation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0021] The liquid volume measuring device of the present invention can accurately measure the volume of the liquid, and can calculate the volume meter of the horizontal tank and the like by using the measured liquid volume and then using the volume calculation special software.

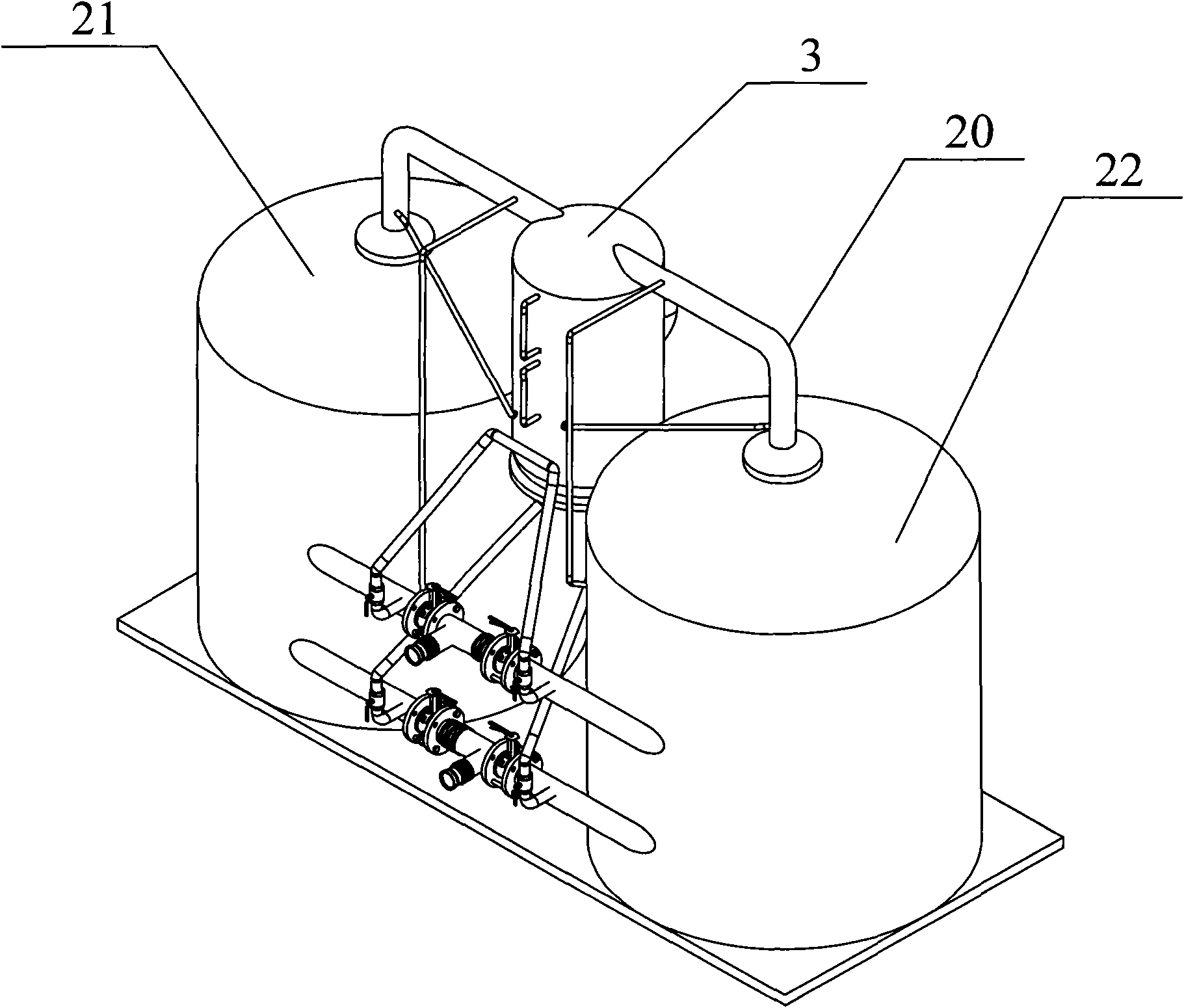

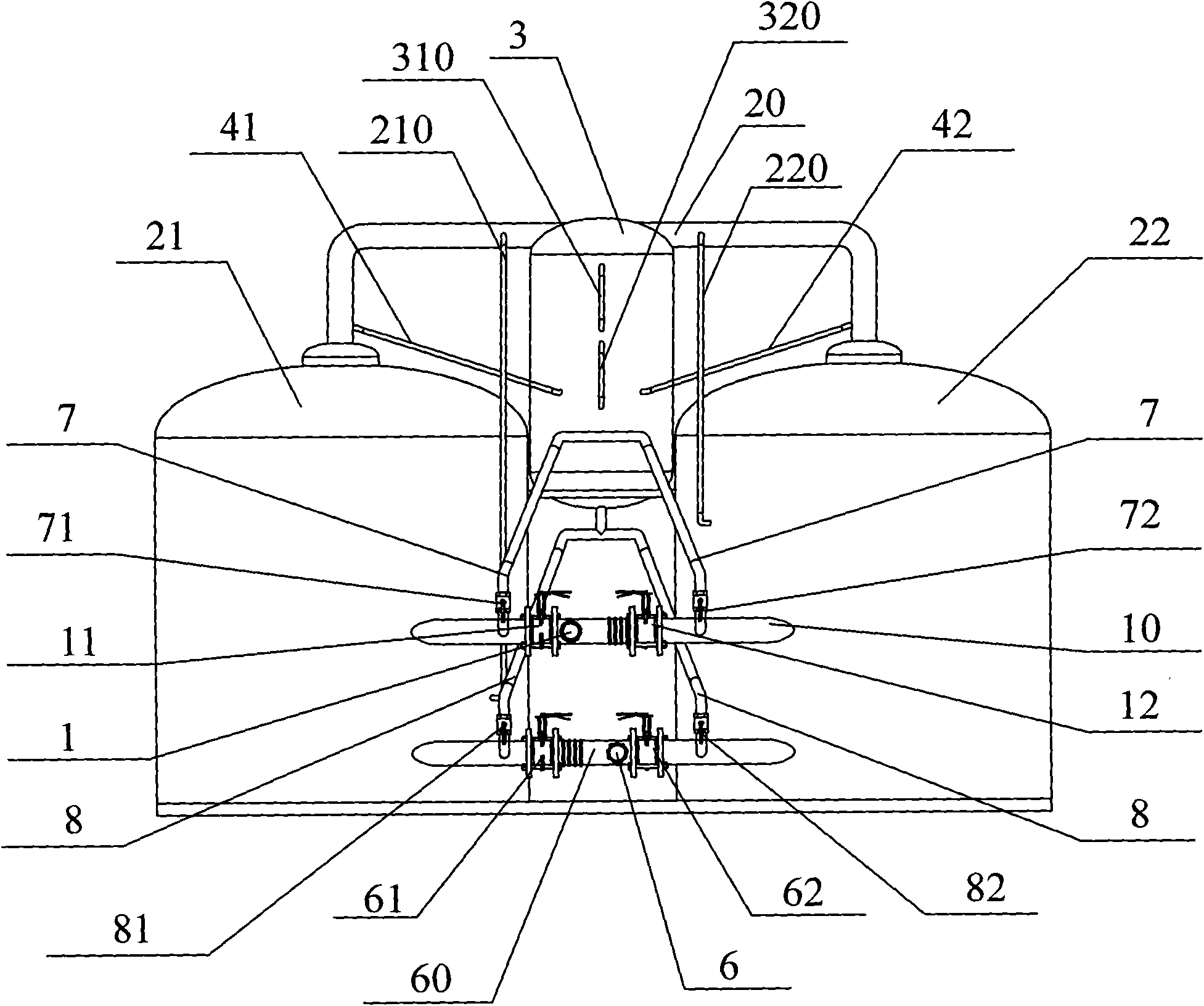

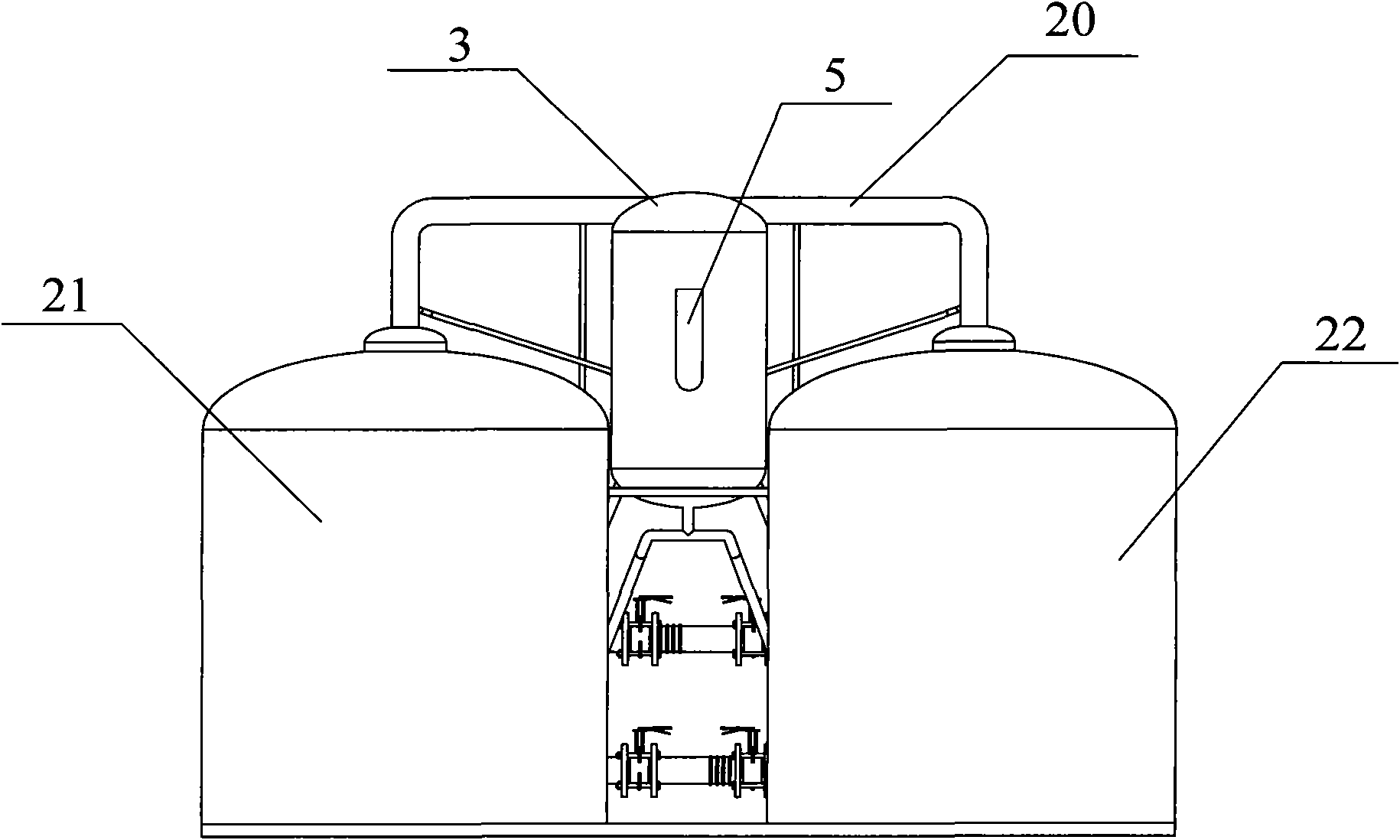

[0022] figure 1 It is a perspective view of the liquid volume metering device of the present invention, see also figure 2 shown in front view, image 3 shown in the back view as well as Figure 4 In the partial sectional view shown, this embodiment takes two oil tanks as an example, of course it is not limited to only two oil tanks for metering, one or more can be provided.

[0023] As shown in the figure, the liquid volume metering device of the present invention specifically includes: an oil inlet 1, a liquid introduction pipe 10, a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com