Laterally adjustable rail fastening system

A technology for fixing mechanisms and rails, which is applied in the direction of rails, fixed rails, roads, etc., and can solve the problems of not improving adjustability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following identical or functionally identical components have the same reference numerals.

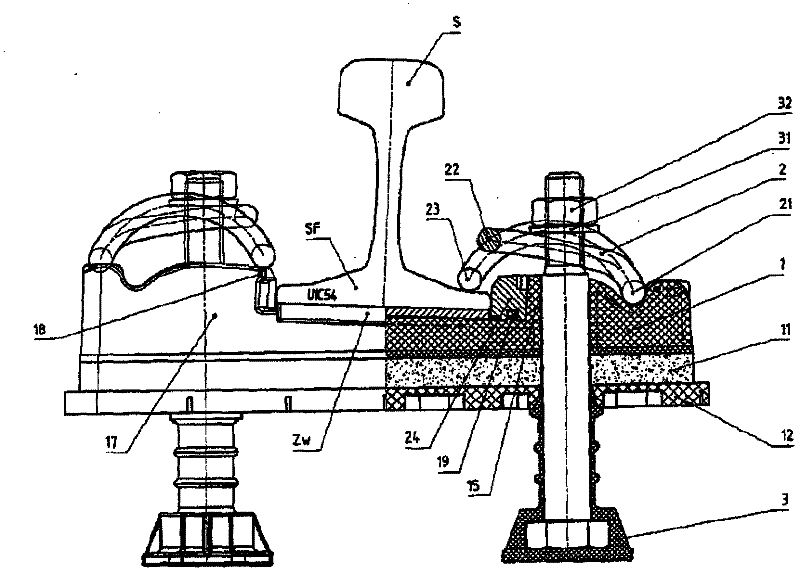

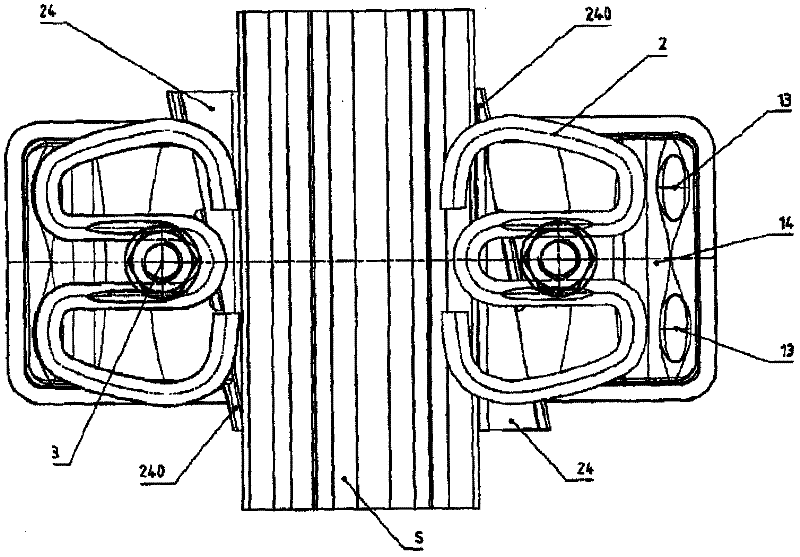

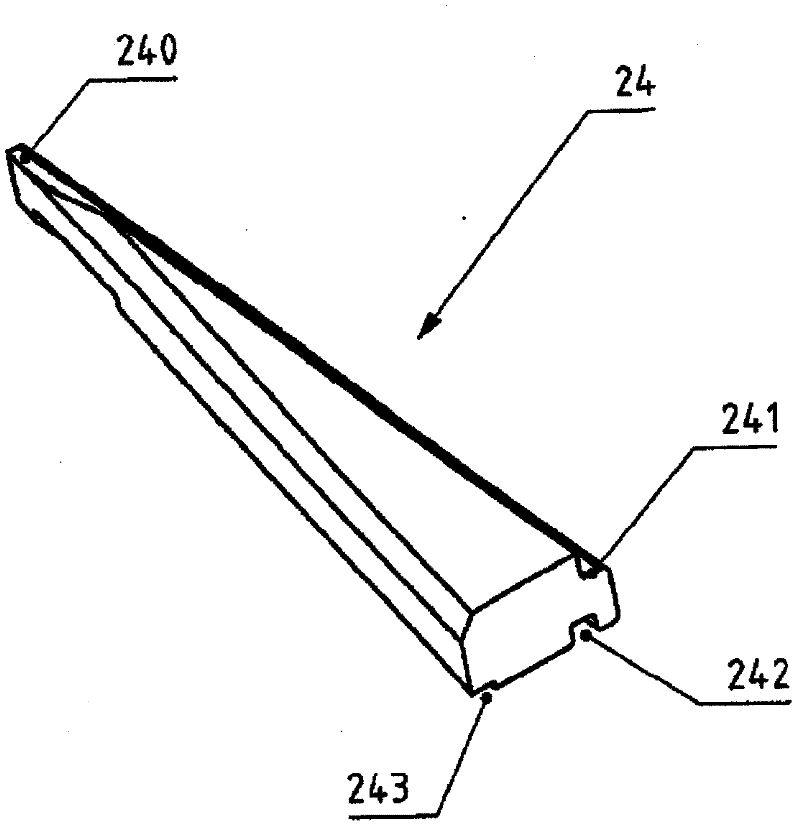

[0030] figure 1 and figure 2 The shown highly elastic support points are known in principle from WO 2005 / 073466 A1; the contents of this patent application publication which are useful for understanding the present embodiment are hereby incorporated by reference. The present embodiment has gauge adjustment in addition. The base plate 1 (possibly with additional elastic or reinforcing plates 11 , 12 ) is fastened to concrete sleepers (not shown) by means of cast-in bushings and integral sleeper bolts 3 . The UIC54-type rail S rests with a rail foot SF with a rail pad ZW in between, on a base plate 1 which, in principle cross-section, is configured like a rib plate with ribs 17, 16, In this case, however, it is not forged or rolled from steel, but injection-molded from plastic. Between the rail base SF and the ribs 17, 16 there is a wedge 24 ( Figure 3a , 3b ).

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com