Rolling device and method for conditioning a roll surface

A technology of rolling equipment and rolls, applied in the direction of keeping the rolling equipment in an effective state, turning equipment, turning equipment, etc., can solve problems such as implementation difficulties, unclean objects, etc., to reduce production downtime, avoid pollution, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

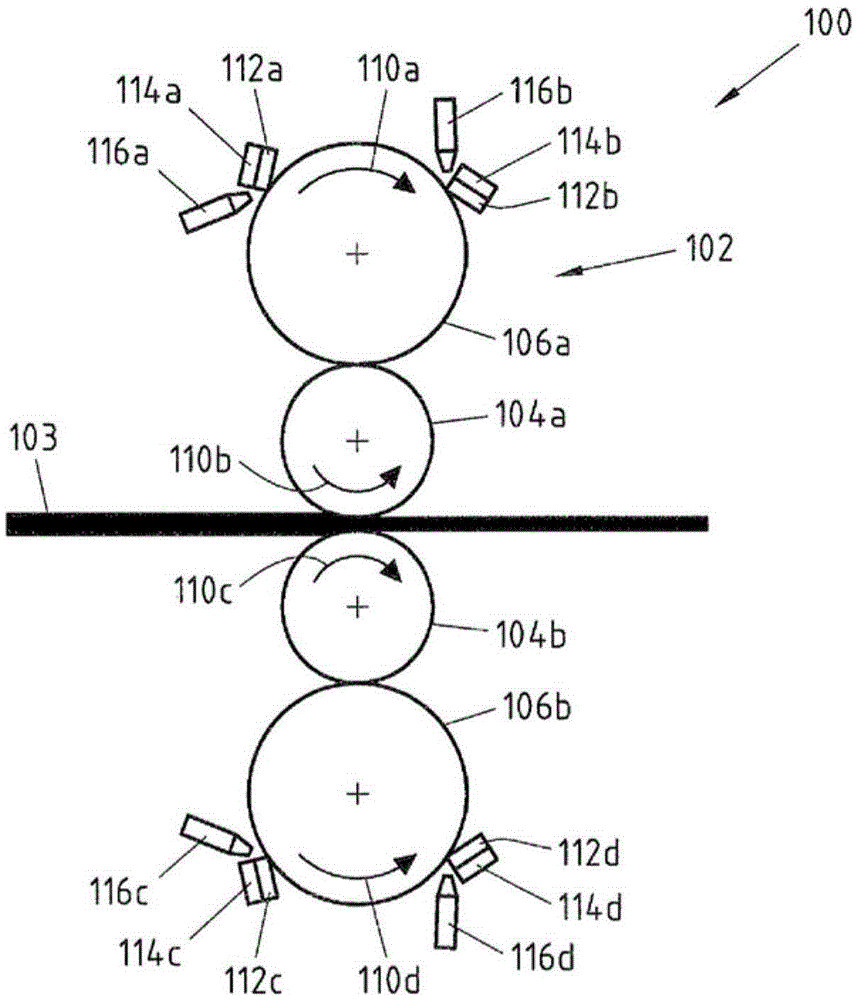

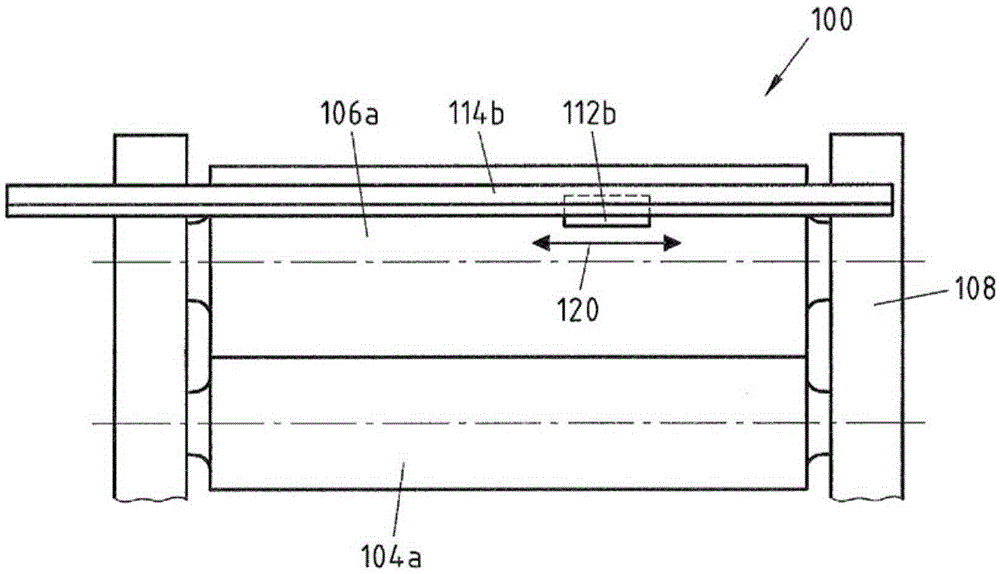

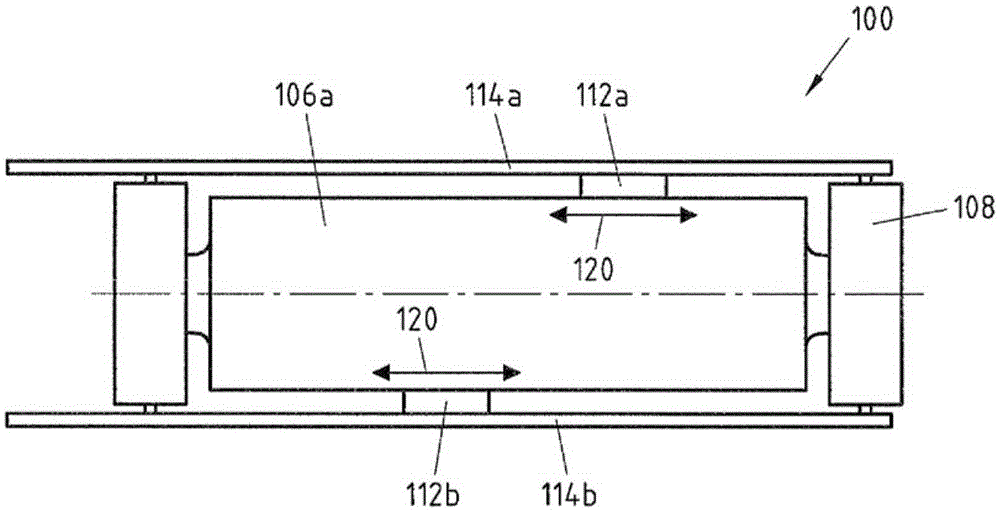

[0074] Figure 1-5 An exemplary embodiment of a rolling installation according to the invention and a method according to the invention is shown. figure 1 A side view of the rolling plant 100 is schematically shown; figure 2 show figure 1 The front view of the upper part of the rolling equipment 100 in ; image 3 shows a top view of the rolling plant 100 at a first point in time during the implementation of the method; Figure 4 shows a top view of the rolling plant 100 at a second point in time during the implementation of the method; and Figure 5 A detailed view of the upper part of the rolling plant 100 is shown from a side angle.

[0075] The rolling plant comprises a rolling mill stand 102 for rolling aluminum strip 103 or aluminum foil. The rolling mill stand 102 is configured as a four-high stand and has first and second work rolls 104a-b, first and second backup rolls 106a-b and a frame 108 in which the rolls are mounted. 104a-b, 106a-b. The rolling stand 102 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com