Novel heat pipe heating system and heat conduction method

A heat pipe, a new type of technology, applied in the field of new powerful heat dissipation equipment, can solve the problems of poor heat dissipation effect, low energy saving efficiency, high production cost, etc., and achieve the effect of large heat dissipation, high efficiency utilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

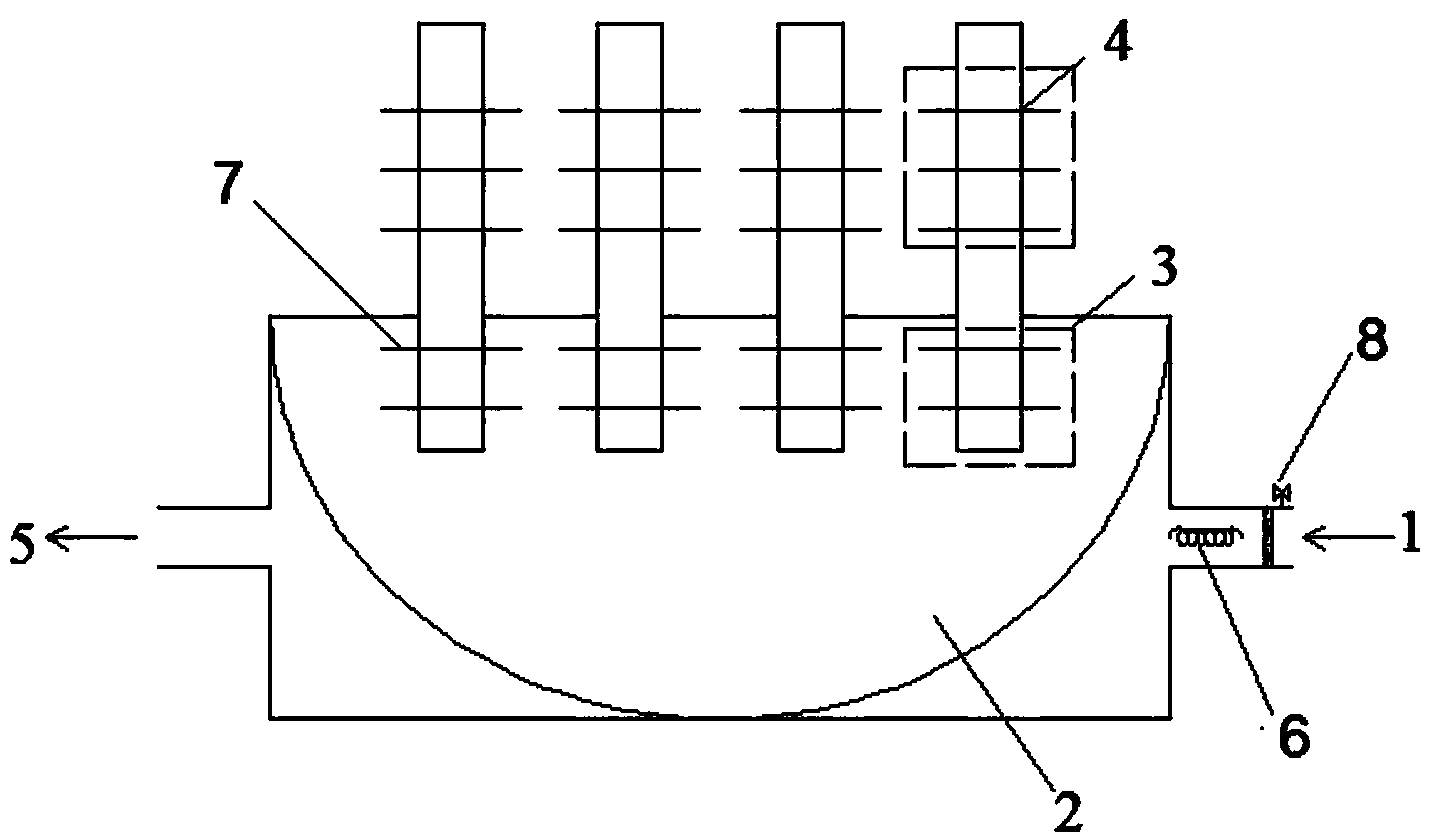

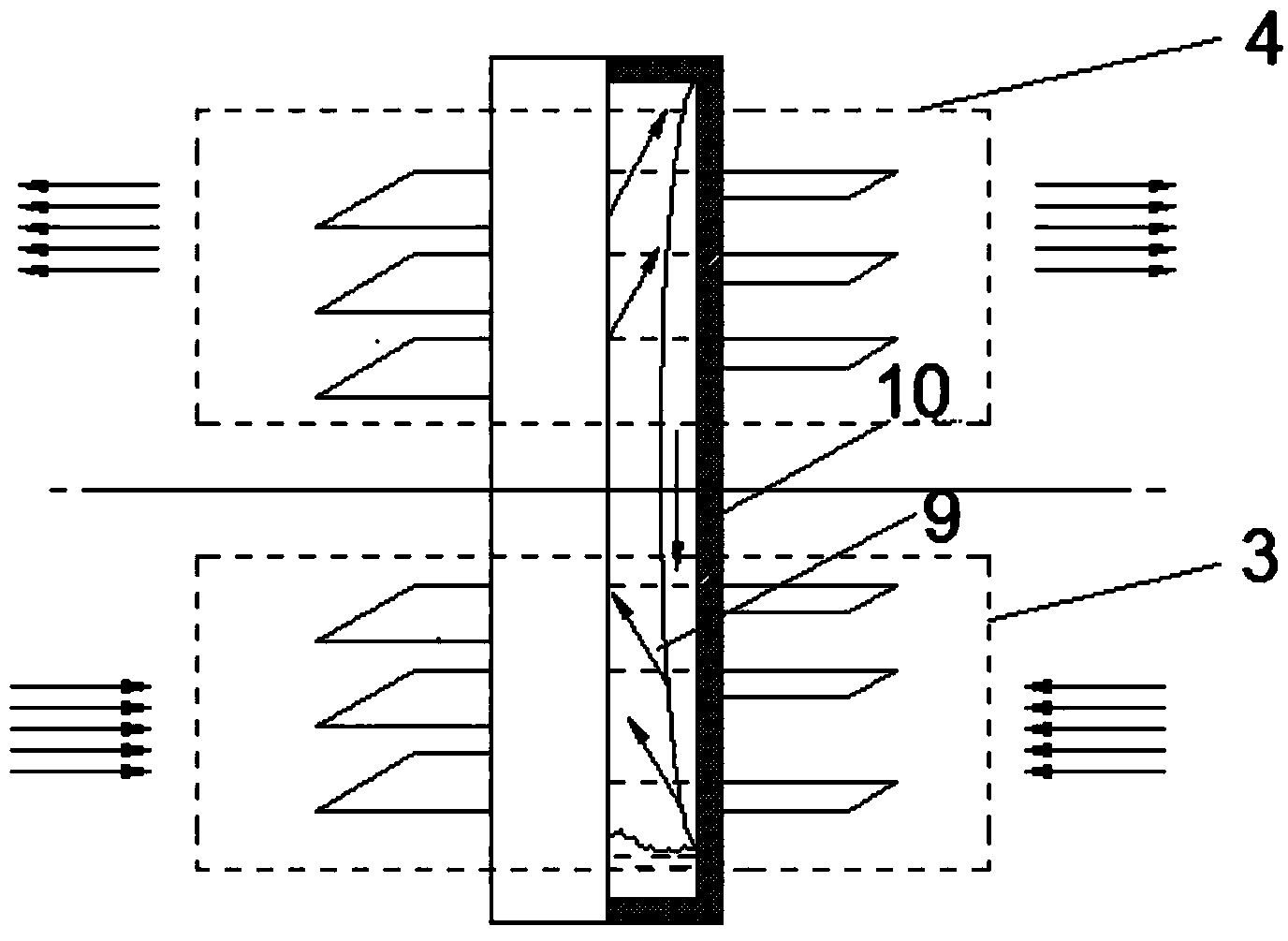

[0017] Such as figure 1 As shown, the new heat pipe heater takes four side-by-side heat pipes as the main components and places them in the hot water reservoir 2. The hot water reservoir 2 uses materials that are easy to conduct heat. Composed, and placed on the lower right side of the reservoir, the hot water outlet pipe 5 is placed on the lower left side of the reservoir, and the water valve 8 is placed above the hot water inlet pipe 1. First, the incoming hot water enters the hot water reservoir 2 through the water inlet pipe 1 (a round pipe with a spiral wire 6 having a smaller cross-sectional area compared to the hot water reservoir 2), and the incoming hot water passes through the water inlet pipe 1 with a certain Speed, and the water inlet pipe has a more suitable cross-sectional area, so that the hot water is in a state of forced convection, and the water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com