Film transfer technology with silica gel protective film as medium

A protective film, silicone technology, applied in layered products, lamination devices, lamination and other directions, can solve the problems of high self-contained film, can not be peeled off in time, etc., to ensure the effect of efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

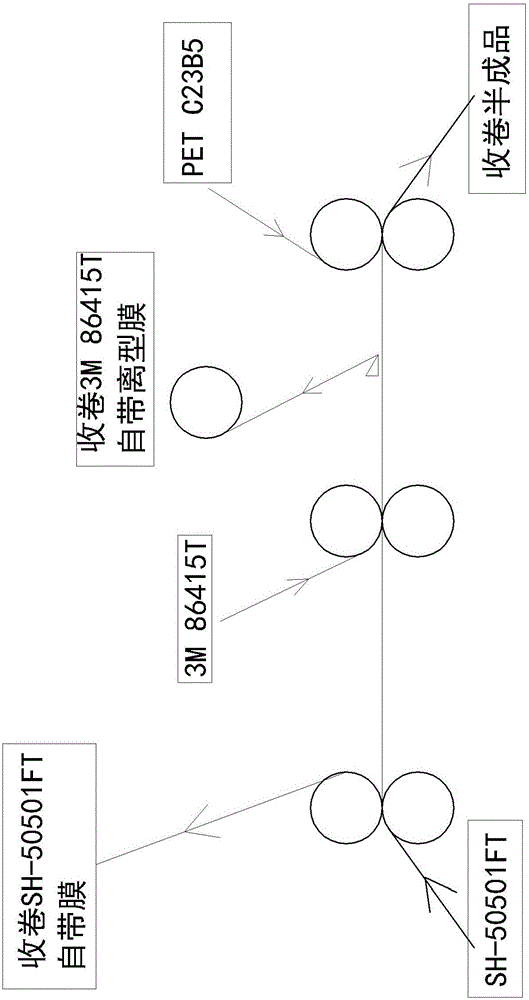

[0021] Specific examples, see Figure 1 ~ Figure 4 : The self-contained winding part of the rewinding silicone protective film SH-50501FT corresponds to the self-contained film, and then the adhesive surface of the silicone protective film SH-50501FT is attached to the adhesive surface of the high-viscosity foam glue 3M86415, and then the self-contained film and high-viscosity foam Adhesive 3M 86415, silicone protective film SH-50501FT forward sequentially, the self-contained film is rewound by the self-contained film winding structure, and the other sticky surface of the high-viscosity foam glue 3M86415 is peeled off, and then the release film pressing roller will release the film PETc23B5 is pressed on the other viscous surface of high-viscosity foam glue 3M 86415, and the semi-finished product is formed by combining PETc23B5 release film, high-viscosity foam glue 3M 86415 and silicone protective film SH-50501FT;

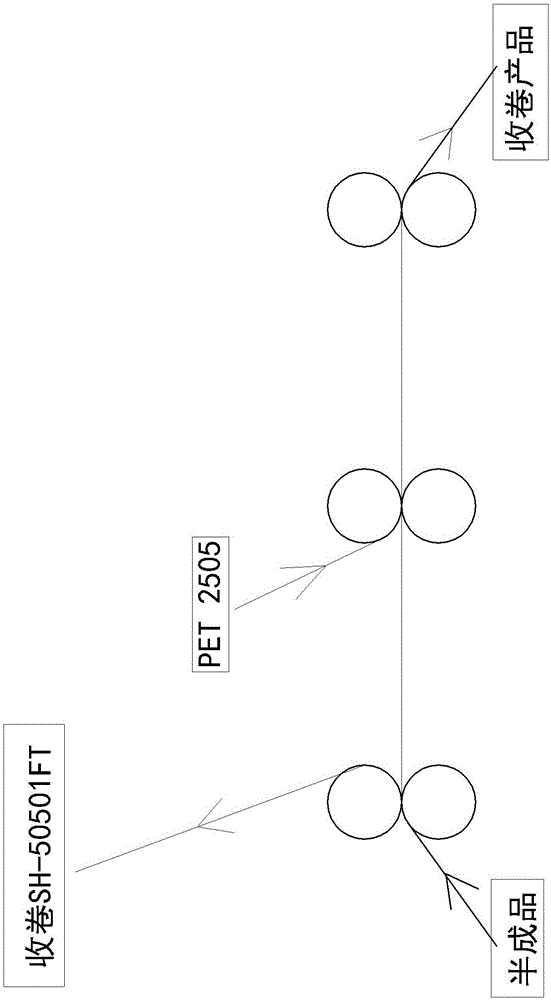

[0022] The product winding line includes a silicone protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com