Cast aluminium rotor punching

A cast aluminum rotor and punching technology, applied to the magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of different iron core lengths, inconvenient production management, long production cycle, etc., to reduce production Cost, simple structure, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

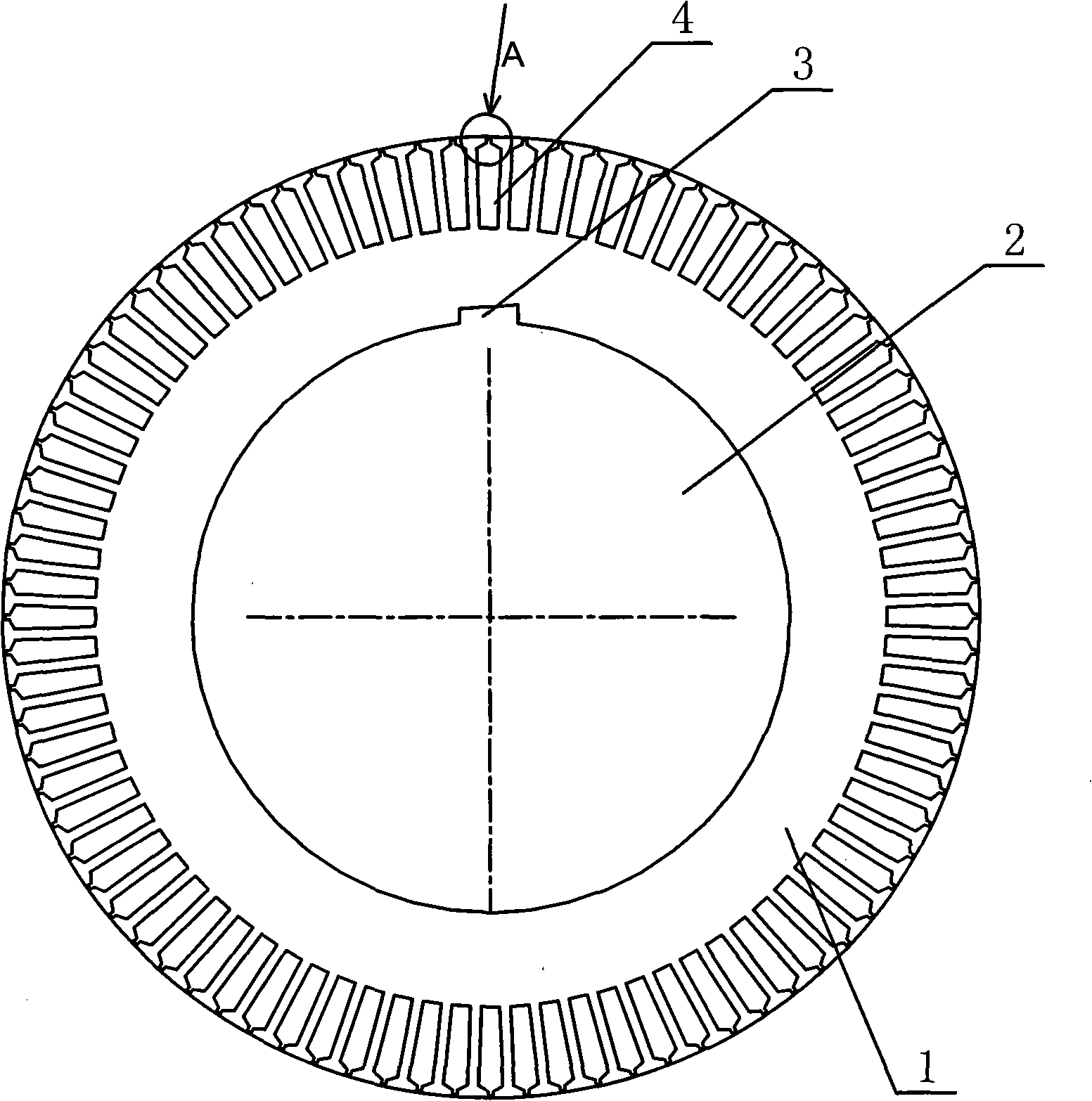

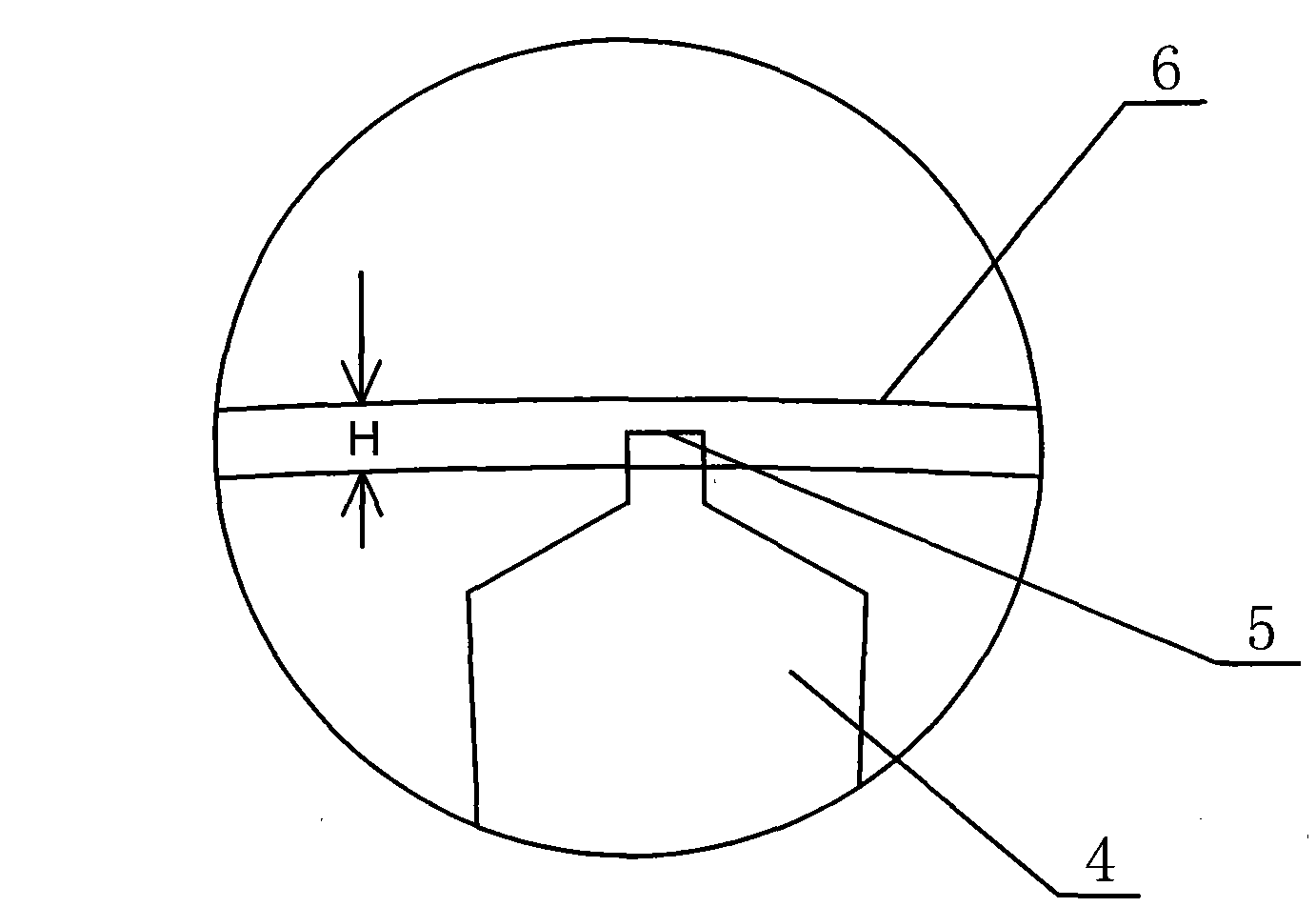

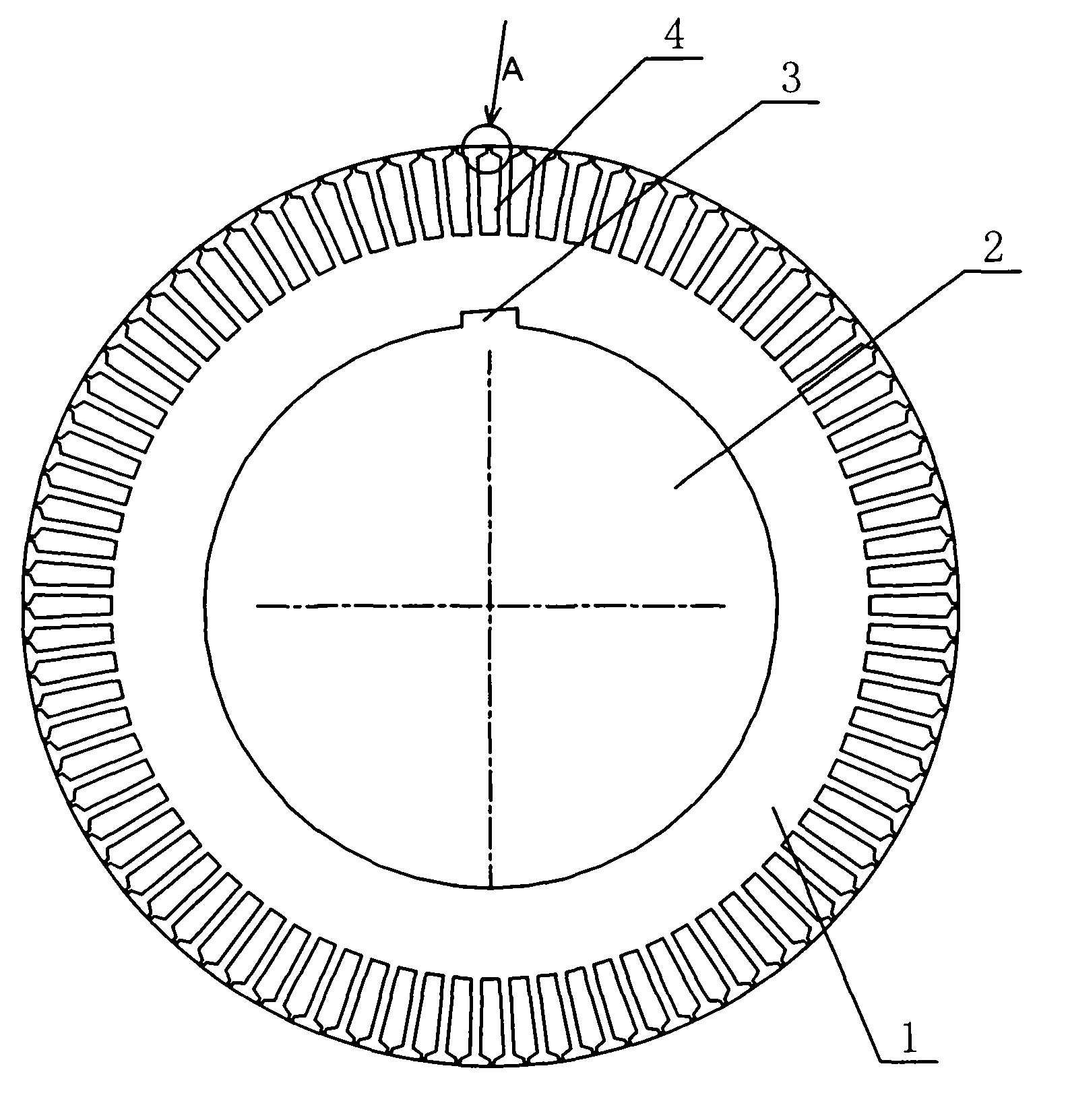

[0014] Please refer to figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of punching a cast aluminum rotor of the present invention; figure 2 for figure 1 Partial enlarged view of A in the center.

[0015] In this embodiment, a cast aluminum rotor punch includes a punch body 1, a shaft hole 2 is opened at the center of the punch body 1, a keyway 3 is opened on the shaft hole 2, and the There are 84 grooves 4 on the radial surface near the periphery of the punching body 1. The grooves 4 adopt a closed groove structure, and the distance between the groove-shaped outer groove 5 and the periphery 6 of the punching body is smaller than the length of the air gap. 0.2mm-0.4mm, the air gap length H is 1.4mm, then the distance between the groove-shaped outer groove 5 and the periphery 6 of the punch body is 1.0mm-1.2mm.

[0016] The groove shape of the above-mentioned cast aluminum rotor punch adopts a closed groove structure. When the rotor is cast a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com