Injection moulding method for plastic water separator

An injection molding and water separator technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of complex core pulling process, unfavorable connection of matching parts, easy damage to the roundness of the end face of the main pipe, etc., to improve the strength and The effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

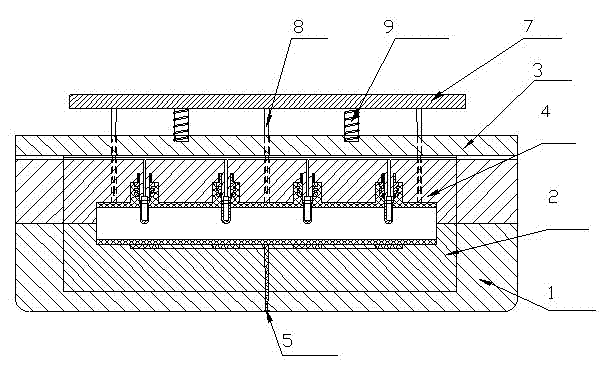

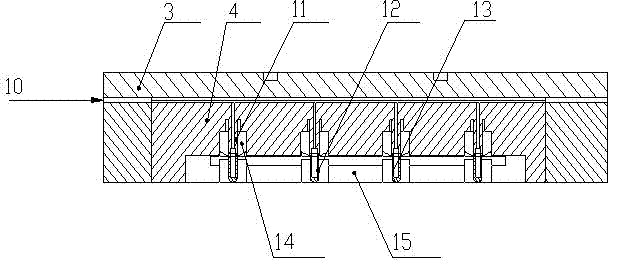

[0027] The working principle of the present invention is as follows: the injection molding method utilizes a main pipe, a metal joint and an injection molding mold to complete, and the injection molding mold includes a front mold, a front mold core, a rear mold, a rear mold core and a feeder, the secondary Injection molding involves the following steps:

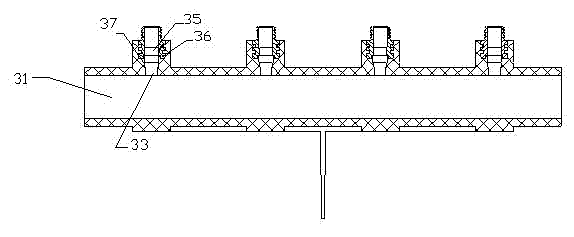

[0028] 1) Firstly, drill the water separator installation hole on the main pipe, and remove the dirt and dust in the installation hole, especially the hole; the water separator installation hole is not less than one;

[0029] 2) Secondly, the outer surface of the insert is covered with rubber, and it is placed on the mandrel of the water outlet of the rear mold core; the insert is a metal joint;

[0030] 3) Then, tighten the thread of the mandrel end of the water diversion port connected to the heating pipe;

[0031] 4) Next, preheat the installation hole of the main pipe to partially dissolve the rubber near the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com