Fatigue life analyzing method based on Paris formula

A technology of fatigue life analysis and formulas, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

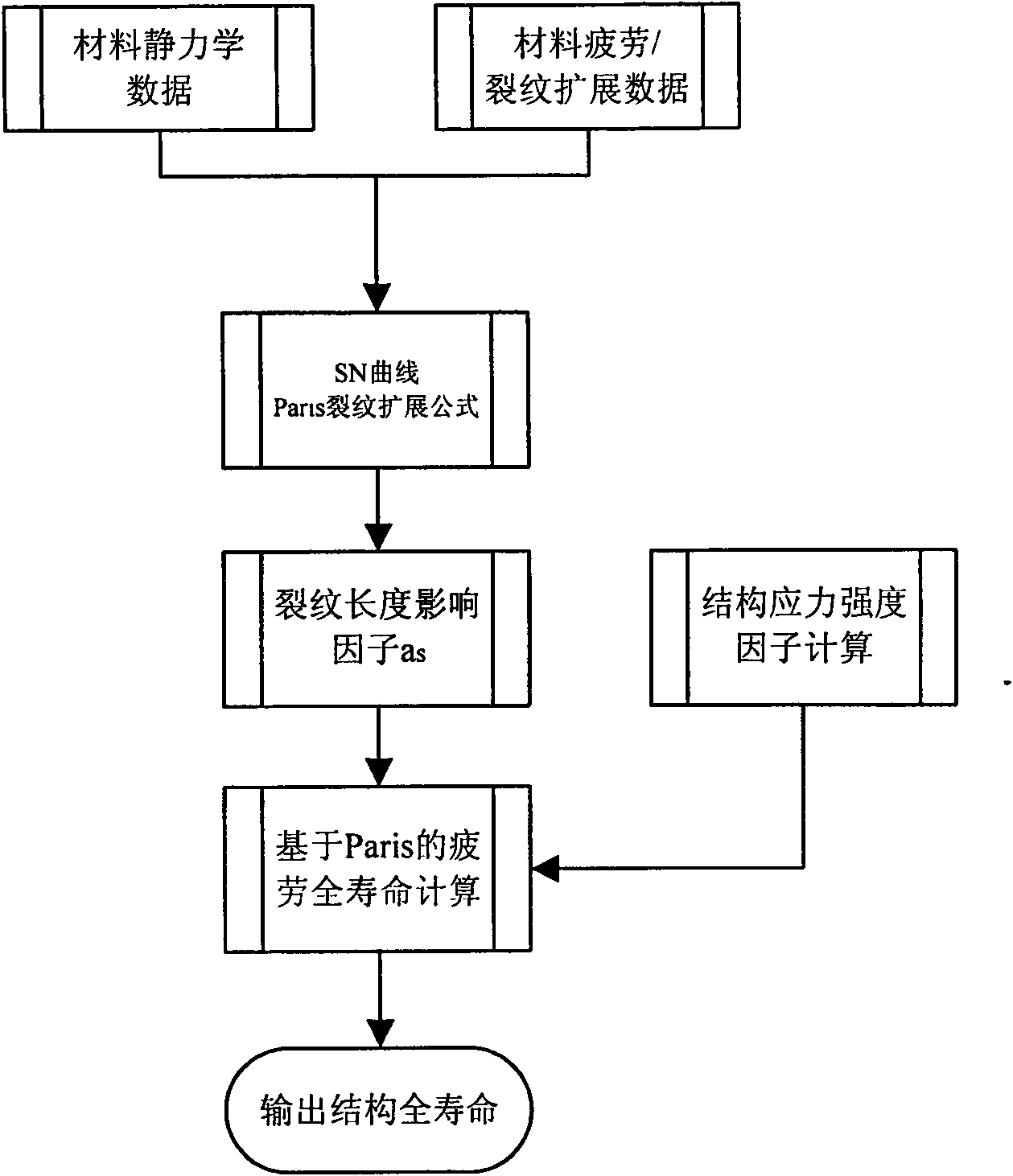

Method used

Image

Examples

Embodiment Construction

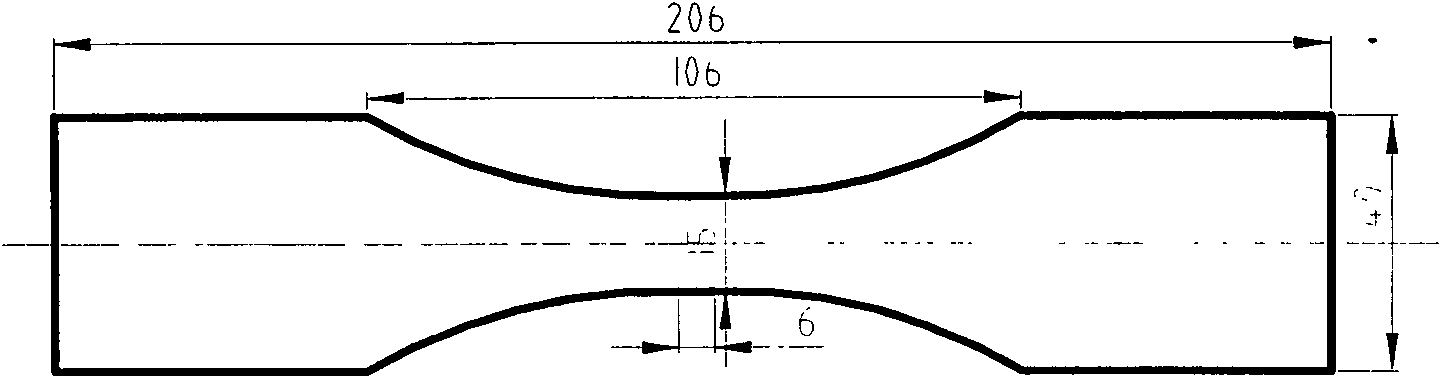

[0055] Method implementation case: take the fatigue life calculation of flat standard fatigue specimen as an example to carry out the whole life calculation.

[0056] The analysis selects the material LY12CZ aluminum alloy thin plate smooth sample to carry out the whole life analysis, the sample is as follows figure 1 As shown, the dimension unit is mm, the thickness is t=2.5mm, and w=15mm.

[0057] Step 1: Refer to the "Handbook of Mechanical Properties of Metal Materials for Aircraft Structures" to obtain the static data of the structure, as shown in Table 1;

[0058] Step 2: Consult the "Handbook of Mechanical Properties of Metal Materials for Aircraft Structures" to obtain the Paris crack growth constant and SN curve data with R=0, the data are shown in Table 2;

[0059] Table 1 Static parameters of LY12CZ material

[0060]

[0061] Table 2 Fatigue and fracture parameters of LY12CZ material

[0062]

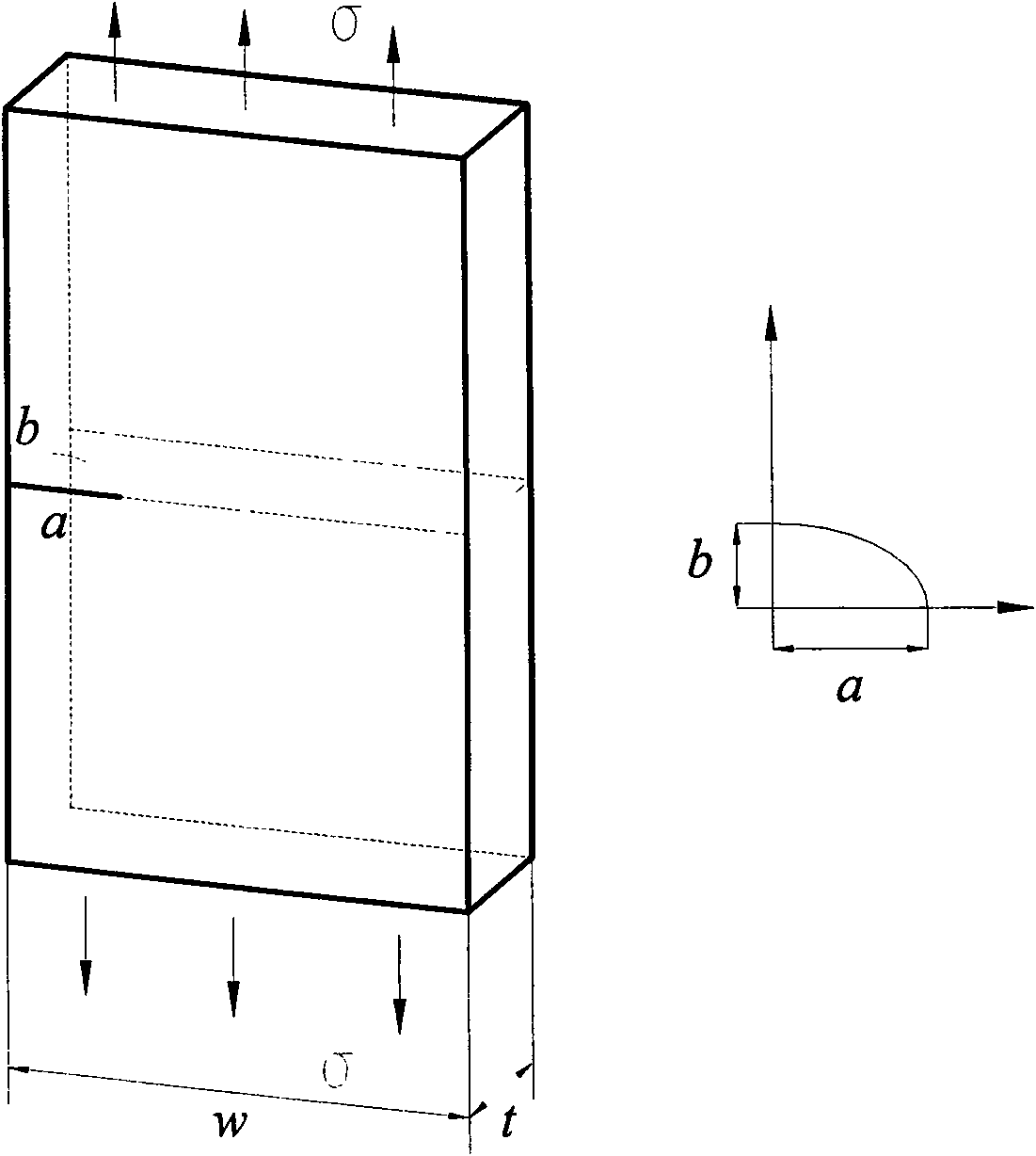

[0063] Step 3: Refer to the "Stress Intensity Factor Handbook" to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com