Dynamic reliability prediction method for permanent magnet semi-direct drive cutting transmission system of coal mining machine

A technology of transmission system and prediction method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of aggravating the randomness and mutation of gear stress, reduce the impact of loading sequence, facilitate parameter adjustment, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

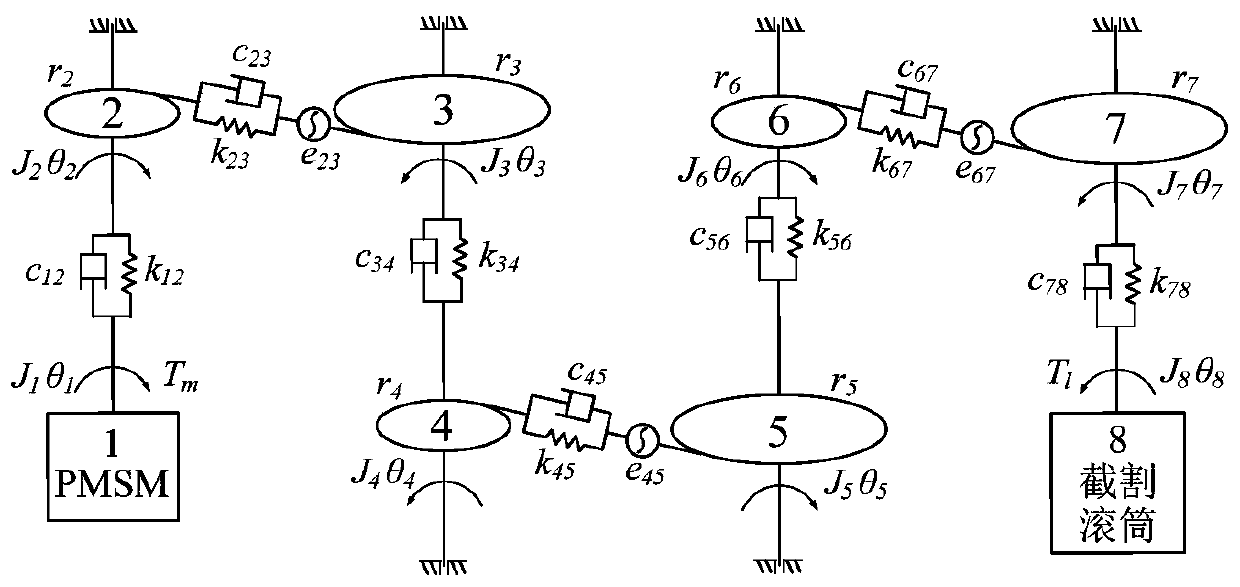

[0040] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described, and the present invention provides a kind of method for predicting the dynamic reliability of shearer permanent magnet semi-direct drive cutting drive system, and its specific steps are as follows:

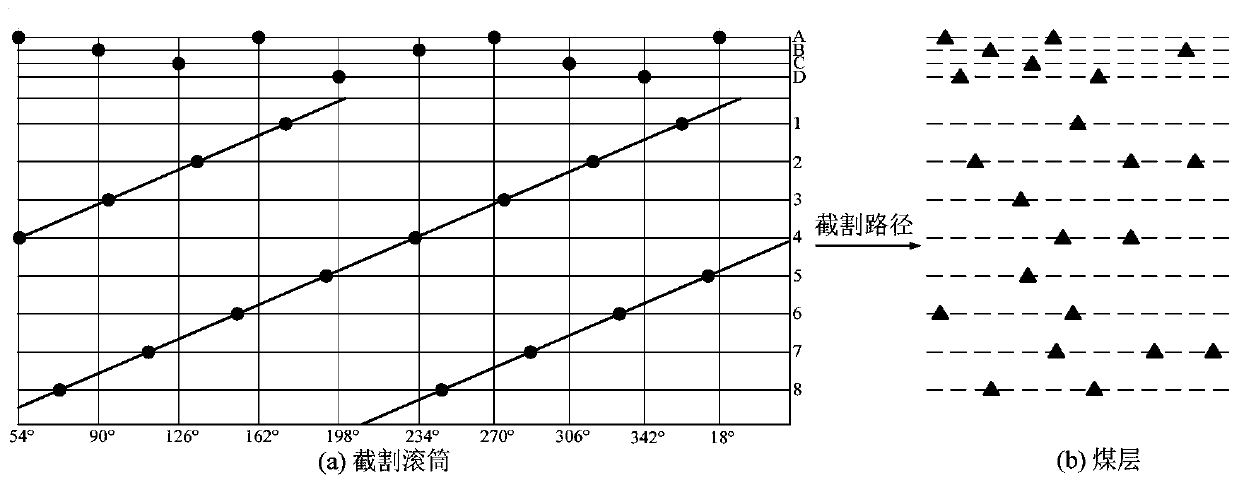

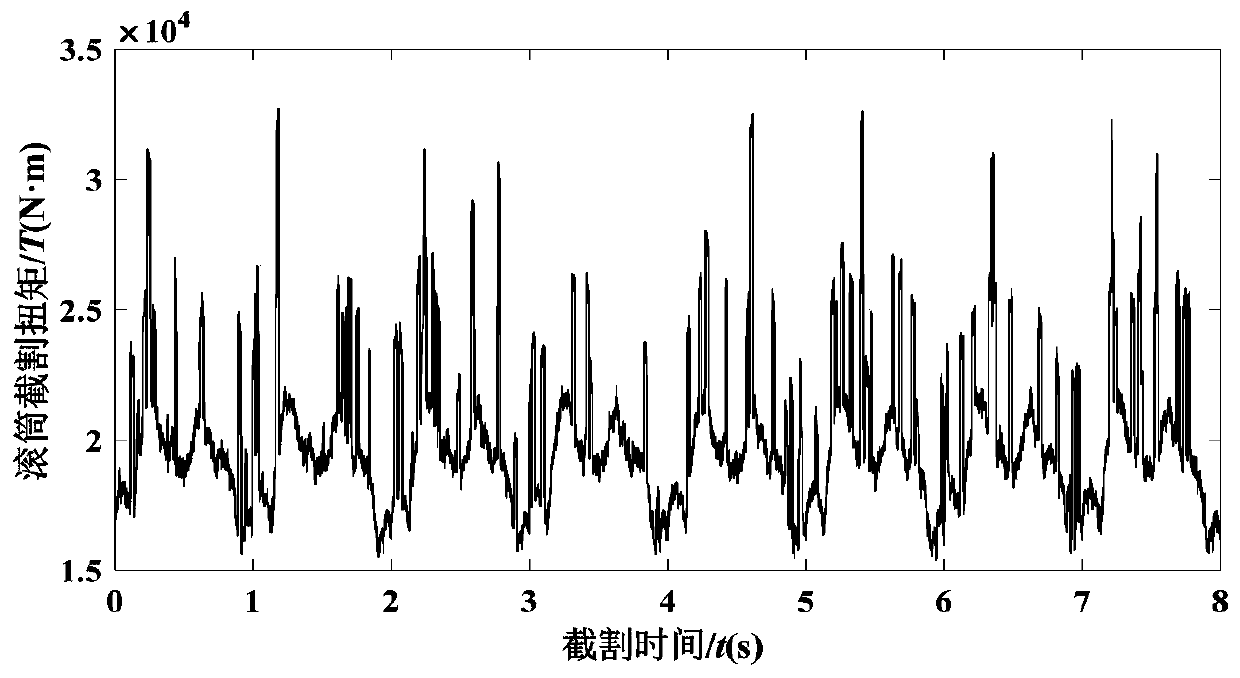

[0041] Step 1), establish cutting drum load model:

[0042] According to the cutting force model of the cutting teeth on the cutting drum, and fully considering the distribution of gangue in the coal seam, the load model of the cutting drum is established as the external load of the transmission system;

[0043] When the pick is mining coal, the instantaneous cutting force Z on a single pick cp for:

[0044] Z cp = Z 0 +100·δ cm ·S a k δ (3)

[0045] where Z 0 is the cutting force when the pick is sharp; 100·δ cm ·S a k δ is the increment of cutting force after the pick is blunted, δ cm is the uniaxial compressive coefficient of the coal-rock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com