Method for manufacturing resistor end effect curves of thick-film integrated circuit

A technology of effect curves and integrated circuits, applied in circuits, electrical components, electrical digital data processing, etc., can solve problems such as design errors of thick film resistors, achieve the effect of improving the design technology level and ensuring the consistency of resistance values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

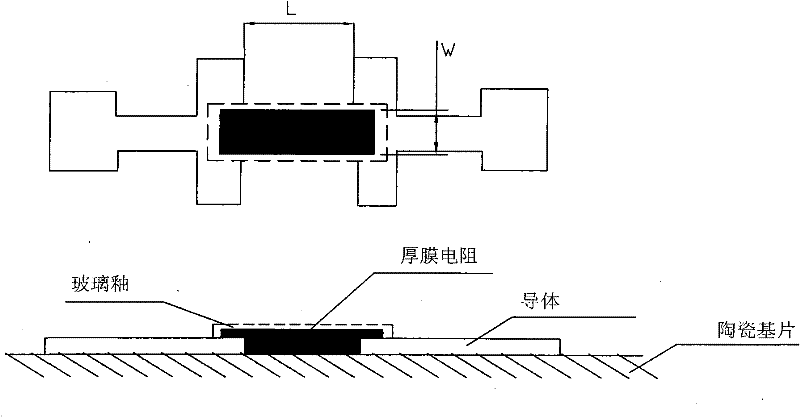

[0027] 1. Layout design

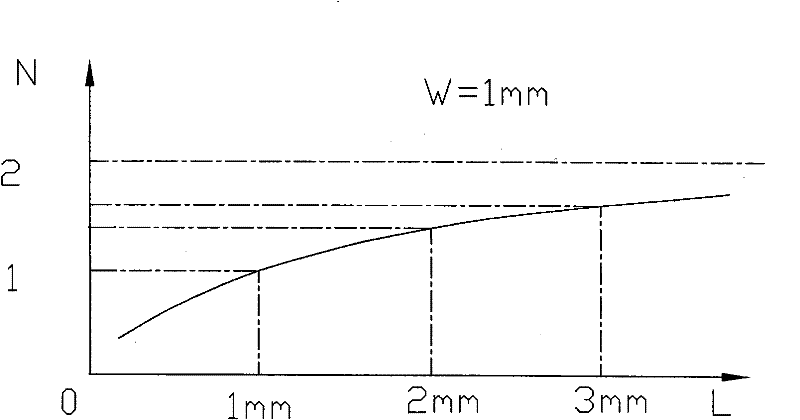

[0028] To draw the design curve of the thick film resistor is to make the change curve of the length of the thick film resistor and the resistance value of the thick film resistor. In order to explore the relationship between the length of the thick film resistor and the resistance value of the thick film resistor, the actual product must be prepared. By measuring the resistance value of the thick film resistor of the actual product, the length of the thick film resistor and the resistance value of the thick film resistor can be obtained. change curve. Therefore, in order to prepare an actual product, it is necessary to design a thick film resistor terminal effect curve to make a layout. The specific layout design method is as follows:

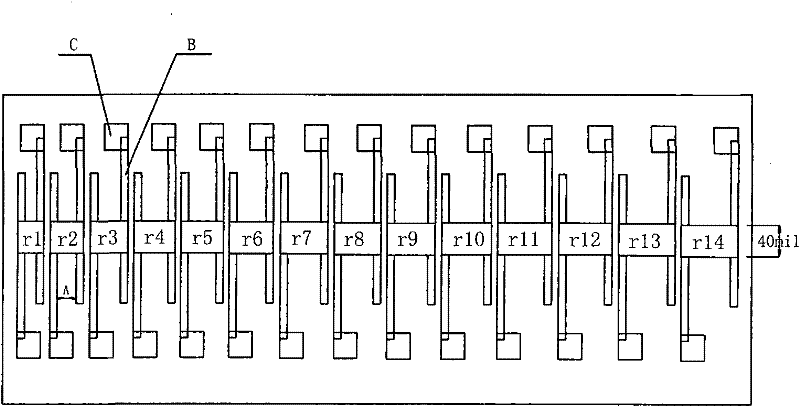

[0029] (1) The layout of the thick film resistor terminal effect curve (resistor width 40mil) is attached. image 3 :

[0030] a. Design conductor layer: used for lap connection of thick film resistor terminals. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com