Thick-film resistor layout design device

A thick film resistor, layout design technology, applied in the direction of calculation, electrical digital data processing, special data processing applications, etc., can solve the problem of lack of design specifications, to eliminate the influence of resistance end effect, solve design deviation, design technology level improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

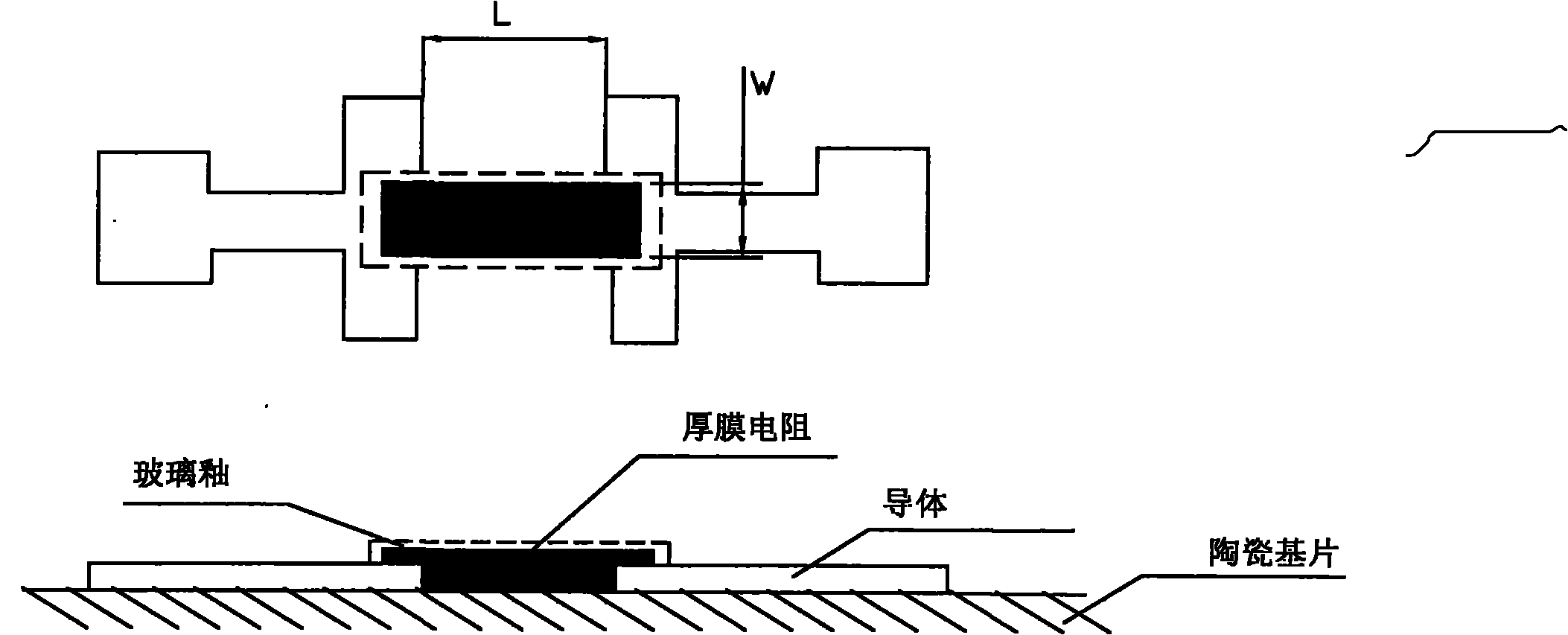

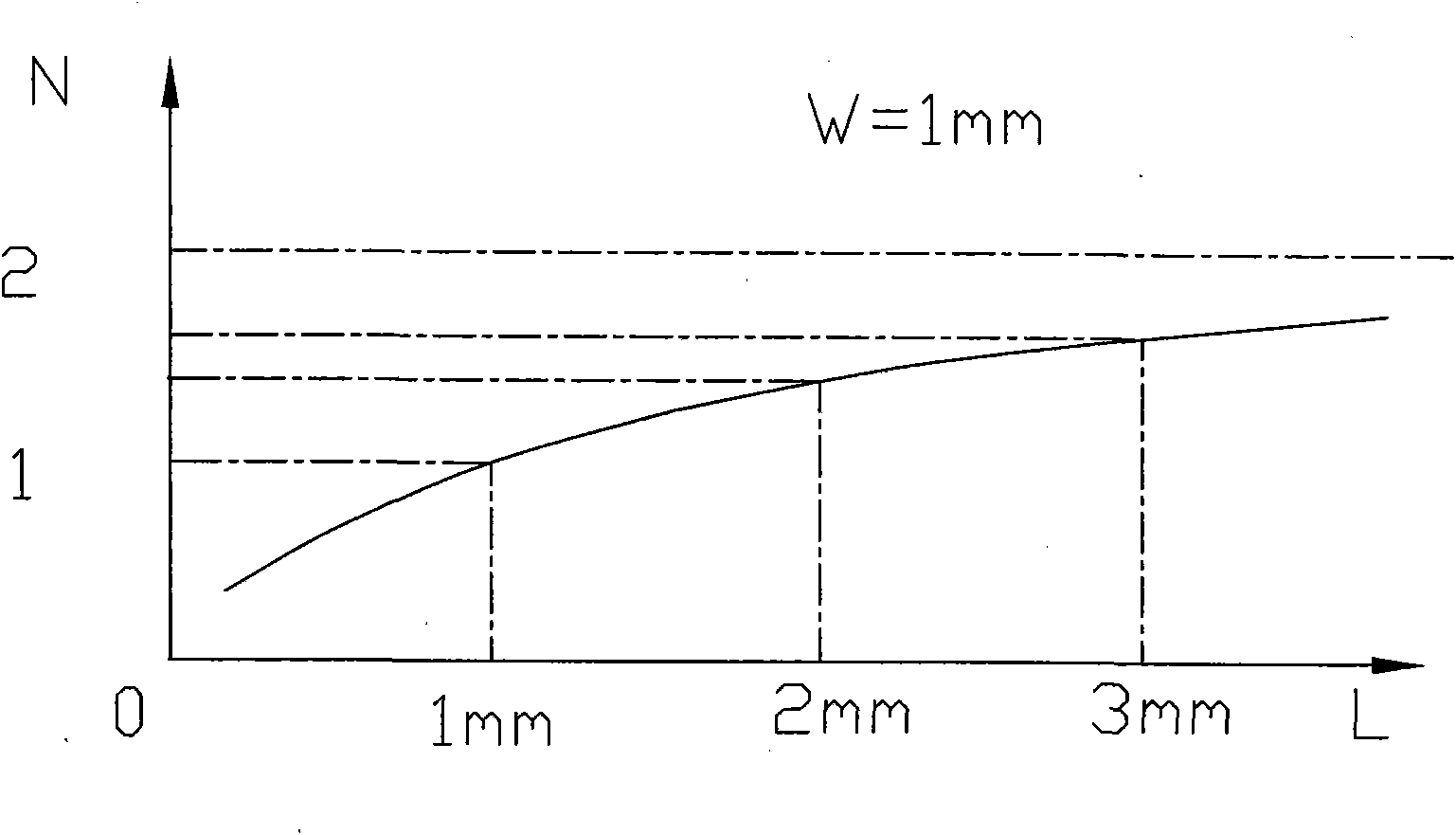

[0029] 1. Determine the end effect curve of thick film resistors

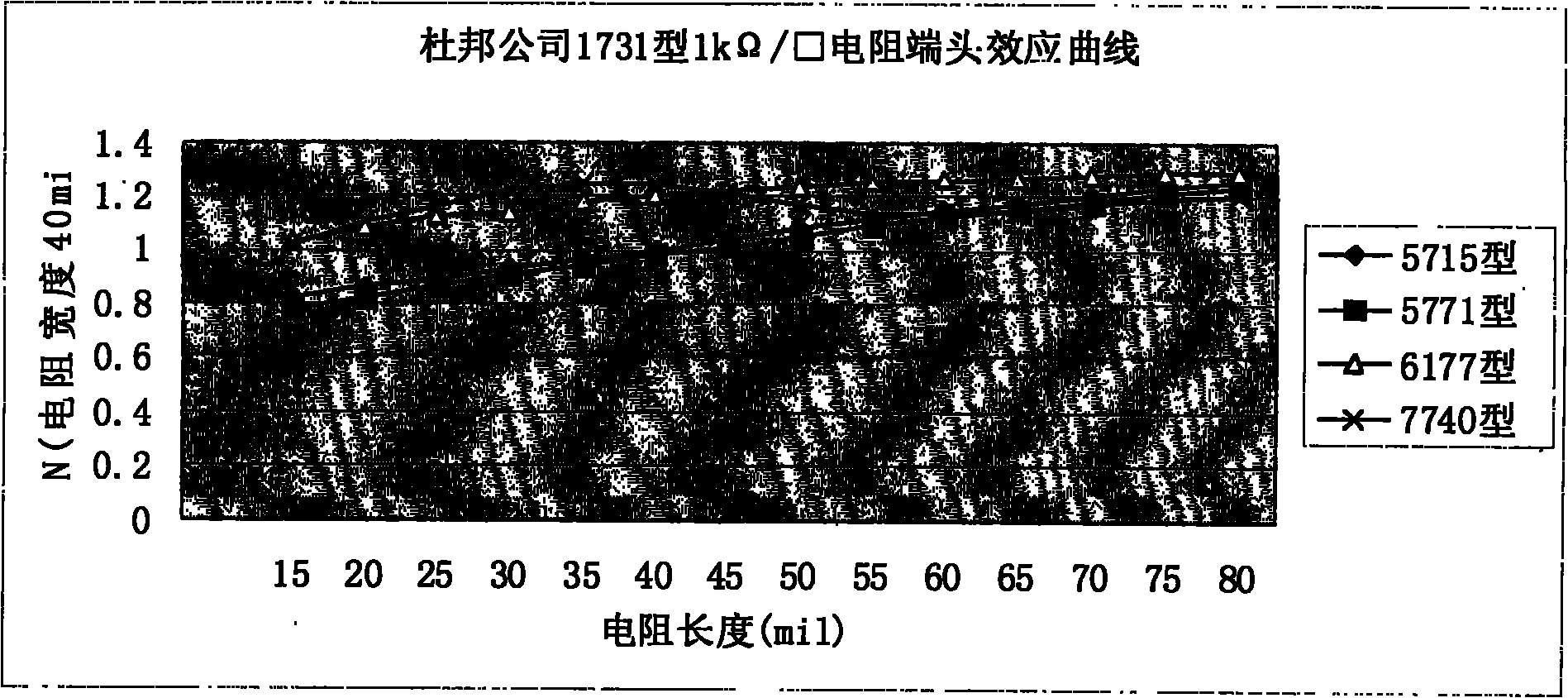

[0030] Necessary conditions for establishing a layout design device for thick-film resistors: According to experiments, the end-effect curves of thick-film resistors (design curves for thick-film resistors at various conductor ends) are obtained. as attached image 3 , Figure 4 It is the tip effect curve of DuPont 1731 type resistor paste.

[0031] 2. Establish a thick film resistor layout design database file

[0032] It is known from the end effect curve of thick film resistors: conductor terminal paste, thick film resistor paste, thick film resistor width, and the one-to-one correspondence between the abscissa L and the ordinate N, we use these information to establish the thick film Resistor layout database files. See the attached block diagram for the specific thick film resistor layout design database structure Figure 5 : Thick Film Resistor Layout Design Database.

[0033] Thick film resistor lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com