Building machine climbing device and self-climbing method and guide seat thereof, and distributing rod

A technology of construction machinery and guide seats, which is applied in the field of construction machinery climbing devices, booms, and guide seats of climbing devices, and can solve the problems of cumbersome lifting process, inability to keep locked guide rails, and low lifting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

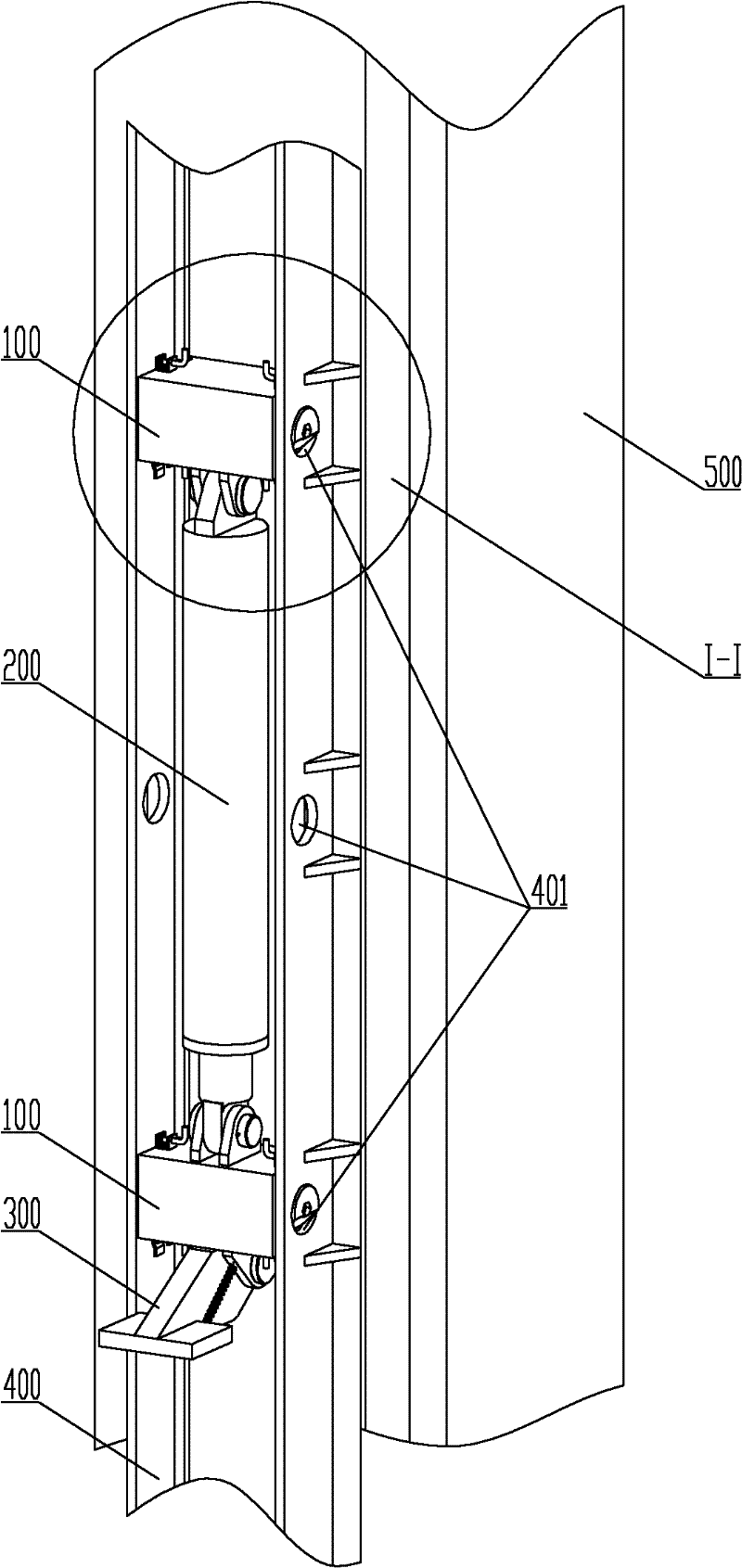

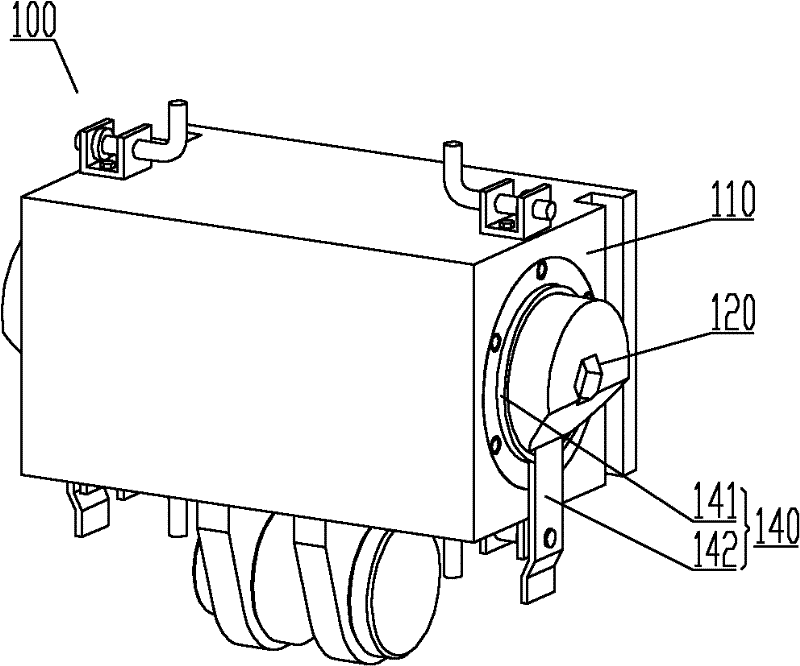

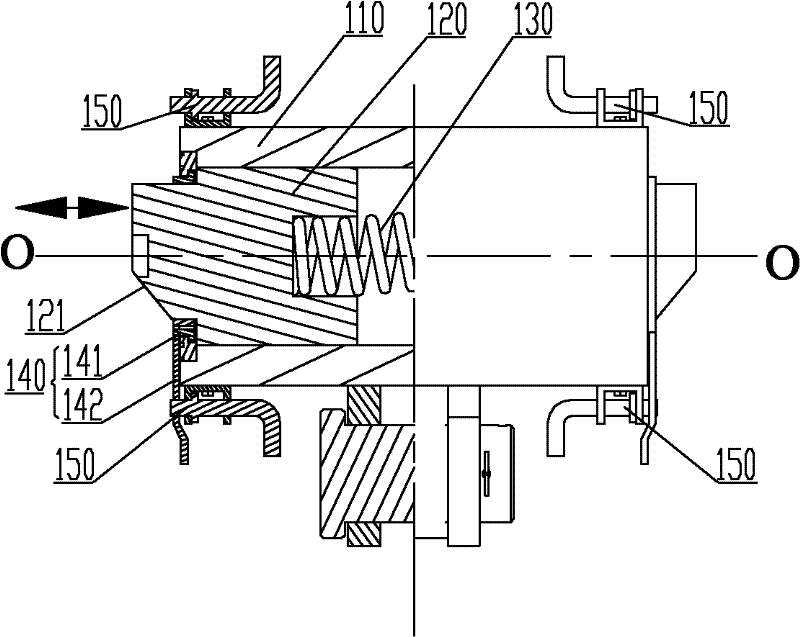

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. For the convenience of description, the following takes the boom as an example to describe the technical solution provided by the present invention; it can be understood that the method and product provided by the present invention can also be applied to other construction machinery, such as climbing tower cranes.

[0047] In the self-climbing method of the driving part of the boom climbing device provided by the present invention, the climbing device includes a guide rail and a driving part, and the driving part includes a jacking drive part and two guide seats, and the jacking drive part can be a jacking The oil cylinder, the two guide seats are an upper guide seat and a lower guide seat, and the upper guide seat and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com