Corrugated cardboard printing machine and multipoint scraper-adjusting and ink-distributing device thereof

A corrugated cardboard and printing machine technology, applied in printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of affecting ink distribution and uneven lamination, so as to avoid the increase of errors in straightness, Improve the accuracy adjustability and improve the effect of ink distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

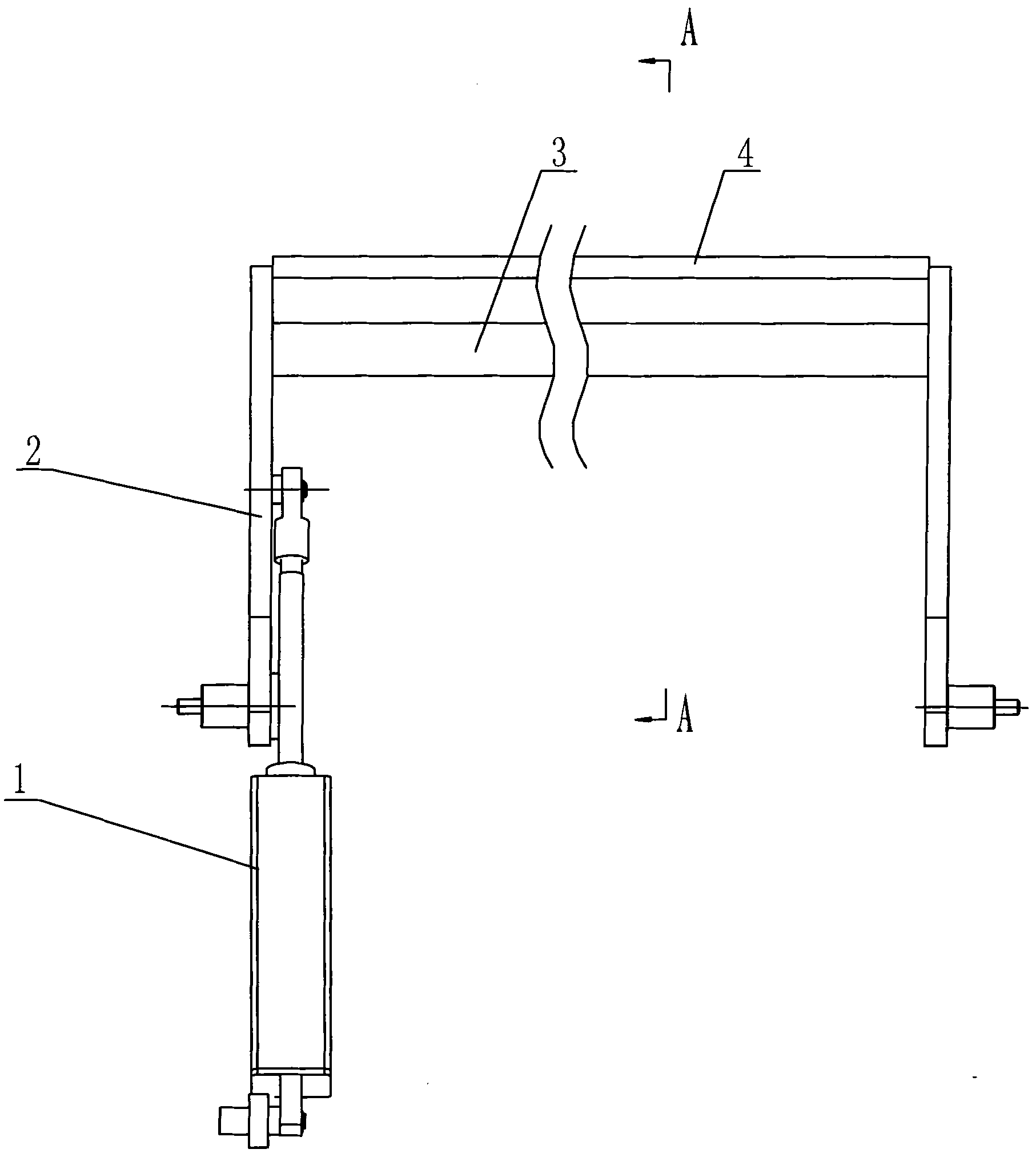

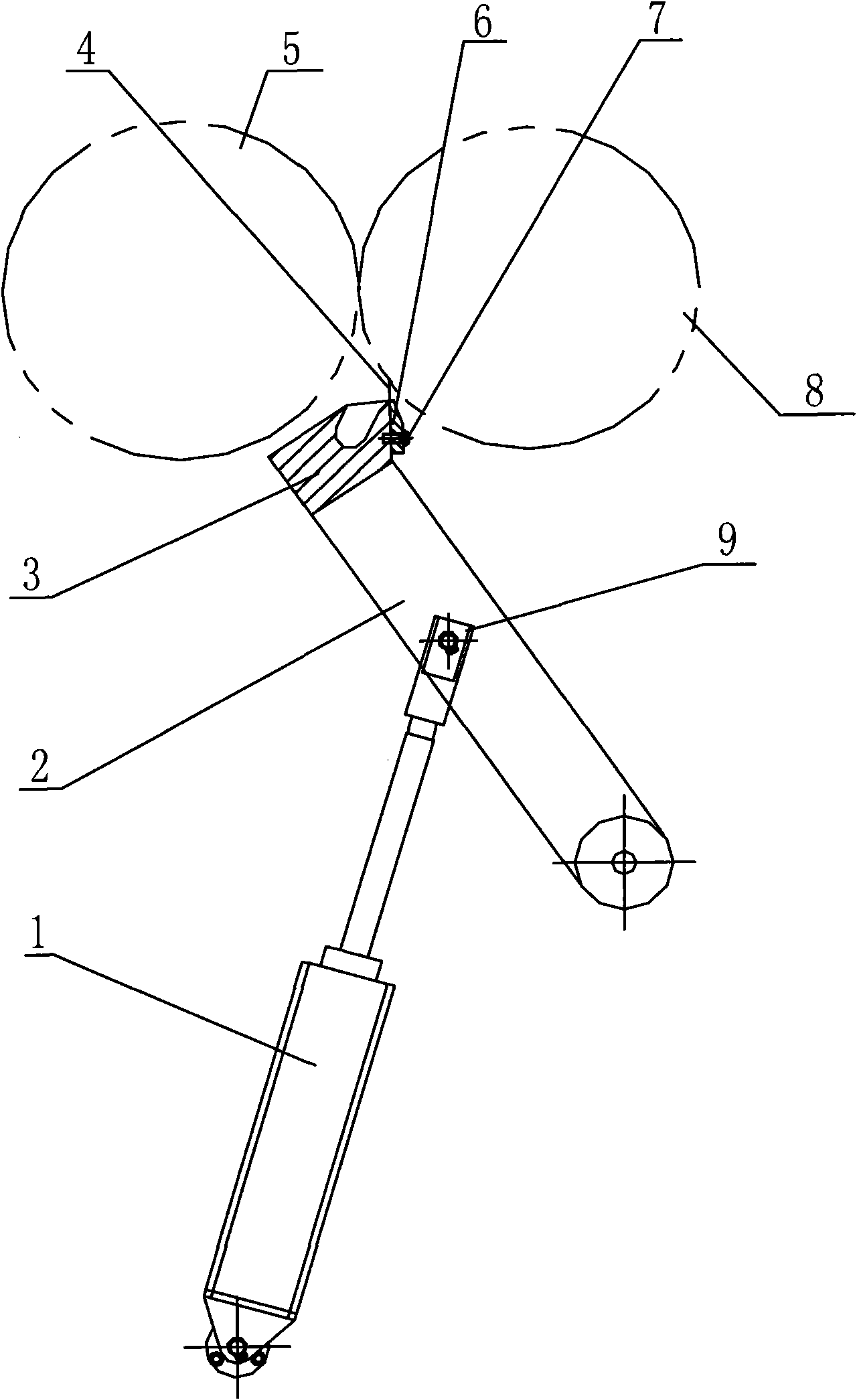

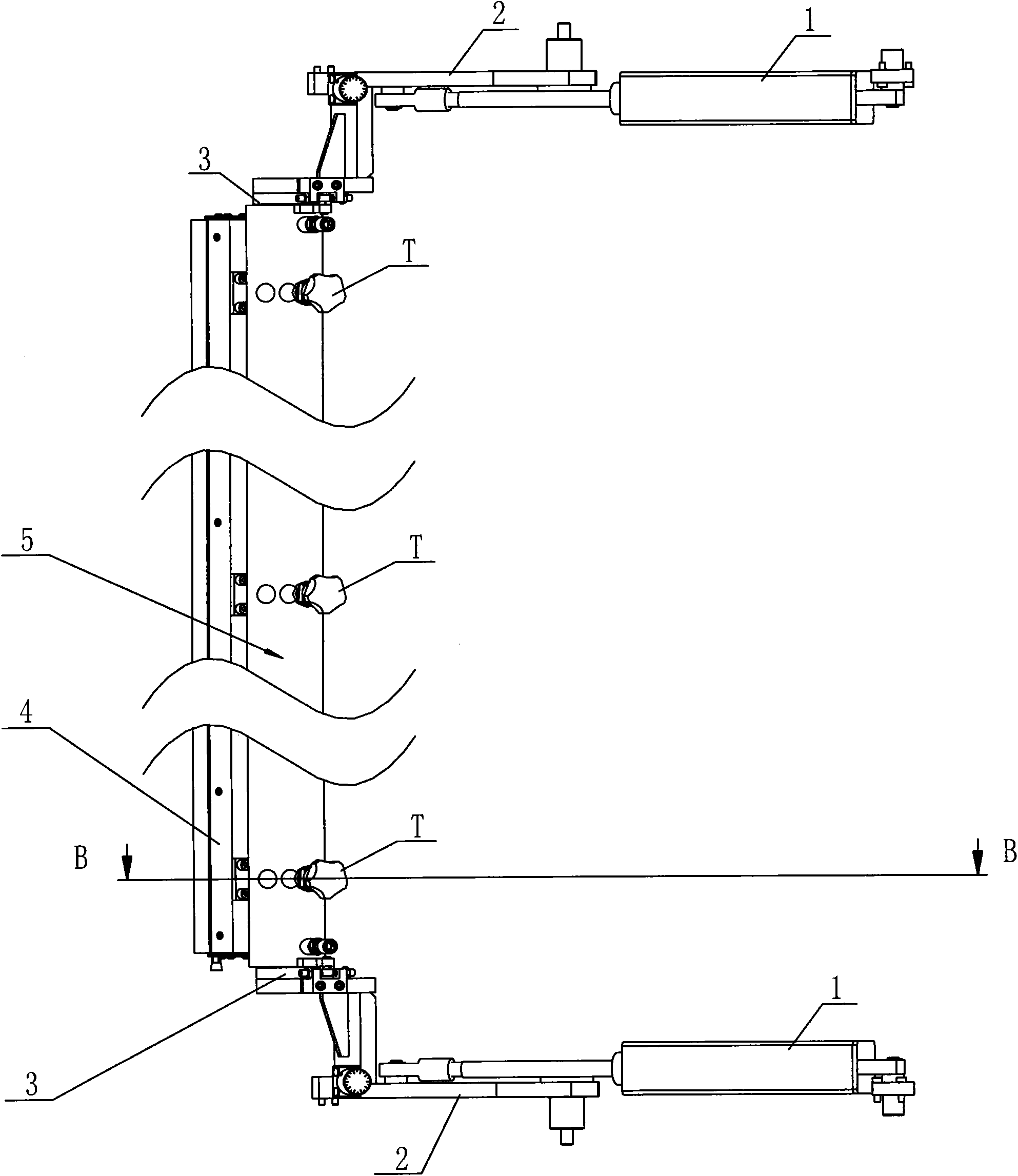

[0029] see figure 2 , diagram 2-1 , Figure 2-2 and Figure 2-3 , the length of the scraper holder 4 exceeds 1.5 meters, and the scraper blade 10 is very thin, with a thickness of about 0.15mm. In order to improve the uniformity of contact between the doctor blade 10 and the anilox roller 12 over the entire length, the concept of the present invention is: the cylinder shaft of the cylinder 1 is hinged with the connecting rod mechanism 2, and the connecting rod mechanism 2 is equipped with a rotary sleeve 3, and the rotary sleeve 3. There is a bearing pin 3-1 on the end face, and the bearing pin 3-1 is inserted in the shaft hole of the joint surface of the connecting rod mechanism 2. The supporting frame 5 is set on the rotating sleeve 3 and locked and fixed with the set screw 19 . The support frame 5 is a circular tube body, and the length is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com