Large-size workpiece weld holder

A technology for large workpieces and welding racks, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. It can solve the problems of difficult work, laborious and time-consuming adjustment process, and low work efficiency, so as to achieve fast positioning and operation. Efficiency, easy positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

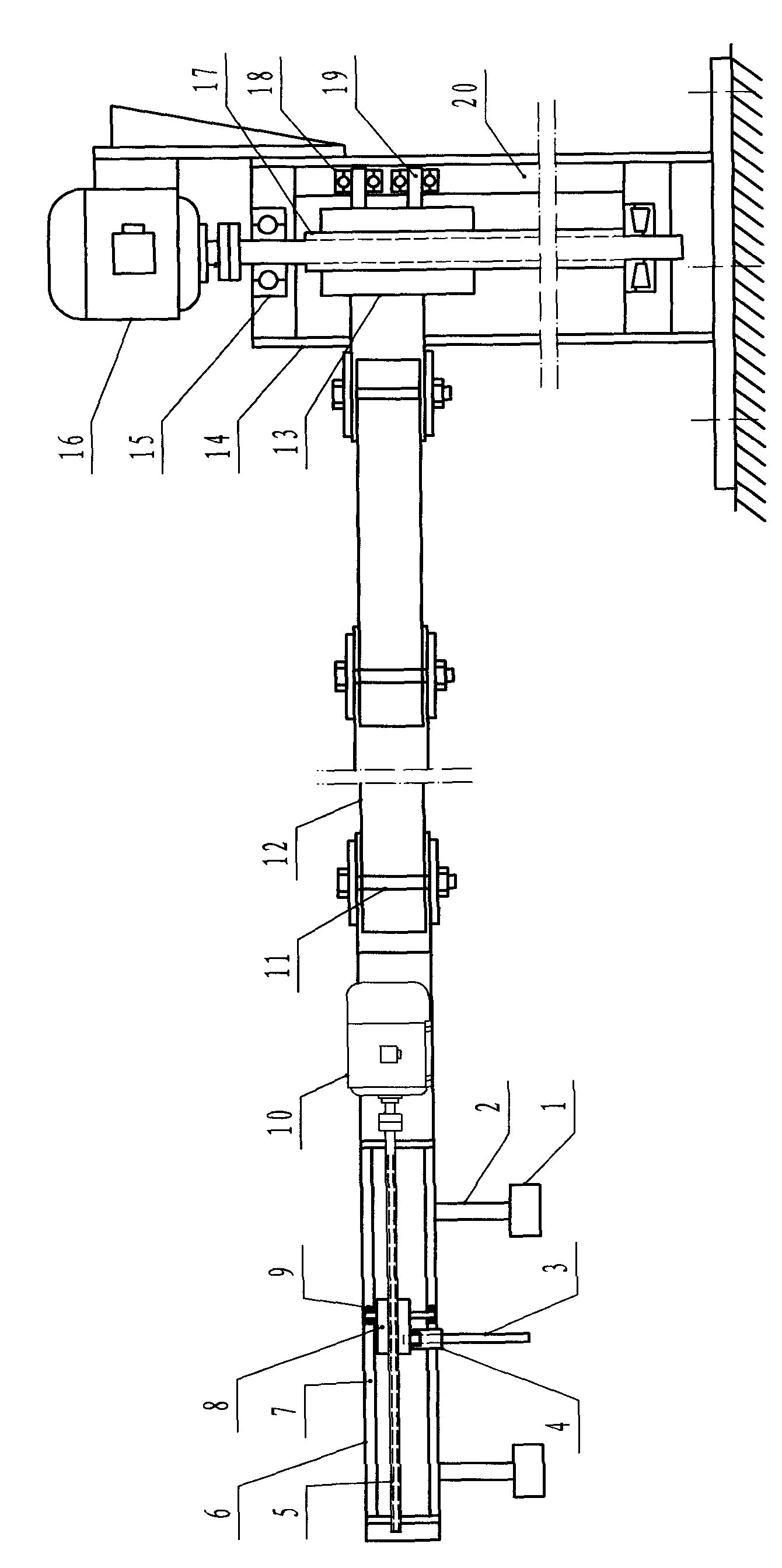

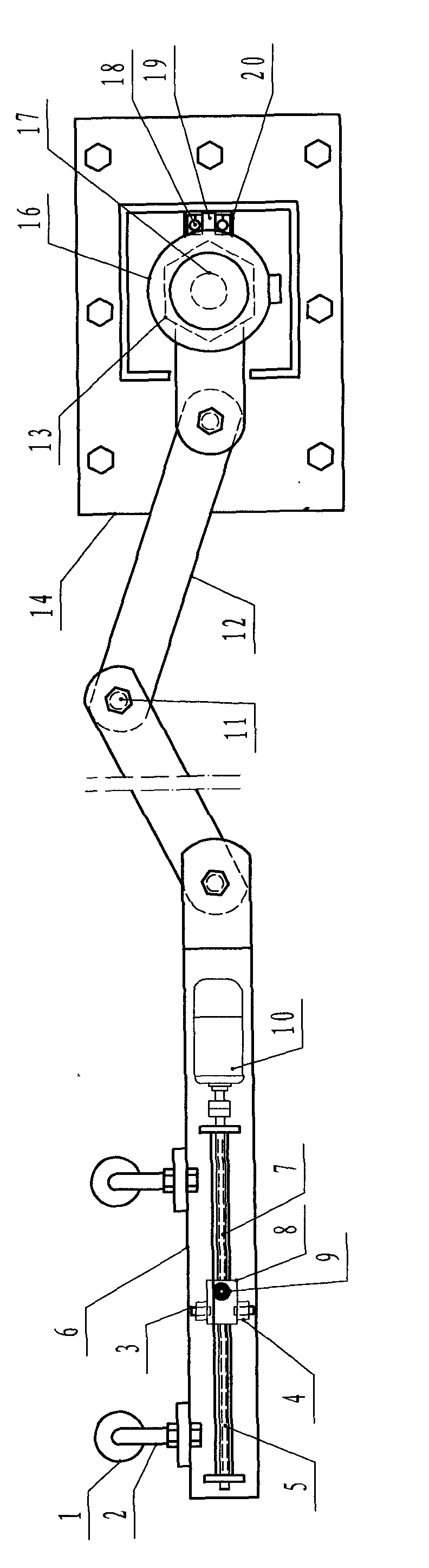

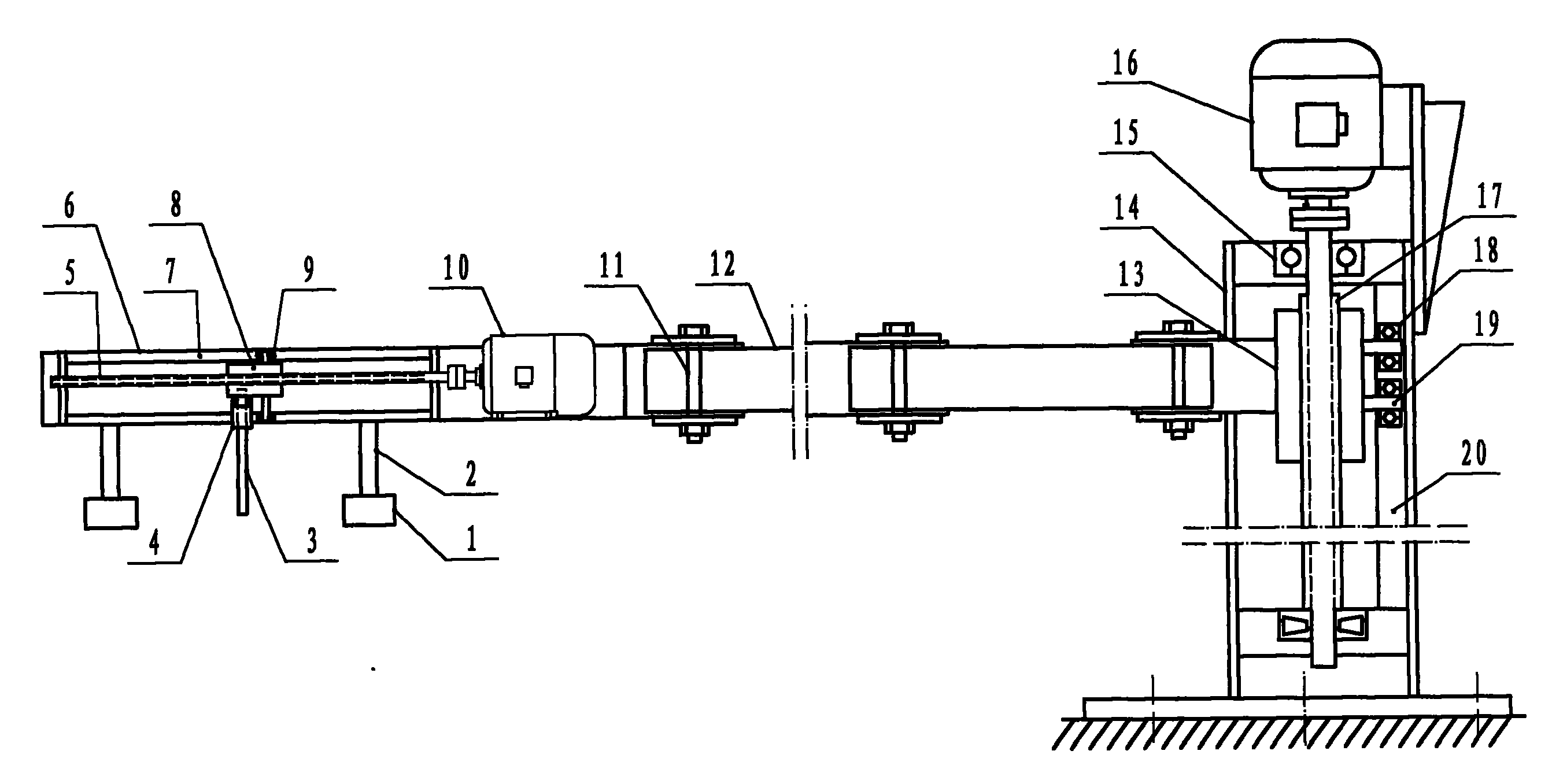

[0009] Example: such as figure 1 and figure 2 As shown in the large-scale workpiece welding frame, its welding torch 3 is installed on the support arm, and the support arm is installed on the frame 14. The support arm is composed of the welding arm 6 and the hinge arm 12. The hinge arm 12 has many joints, and the hinge arm 12 Connect with the rotating shaft 11, the welding arm 6 is fixedly installed on the front end of the hinge arm 12, the welding torch moving motor 10 is installed on the welding arm 6, the welding torch moving screw rod 5 is installed on the rotating shaft of the welding torch moving motor 10, and the welding torch moving screw rod 5 is set Welding torch moving nut 8 is arranged, and welding torch moving nut 8 is positioned by welding torch bearing 9, and welding torch bearing 9 is close on the positioning plate 7 of welding torch, and welding torch frame 4 is installed below welding torch moving nut 8, both sides of welding torch frame 4 Each welding gun ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com