Swing type pneumatic clamping reaction arm mechanism

A pneumatic clamping and reaction arm technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as trouble, delay of production efficiency, and inability to achieve fast and accurate positioning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

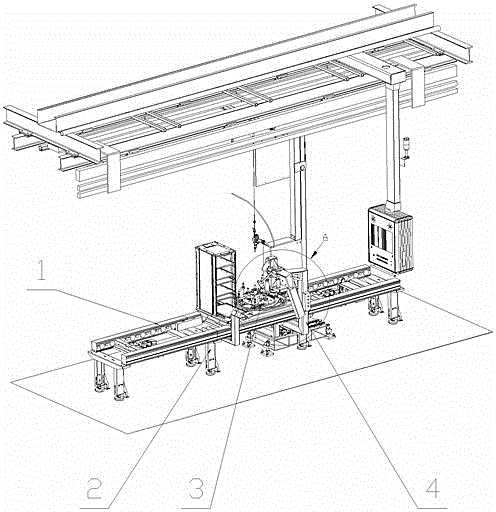

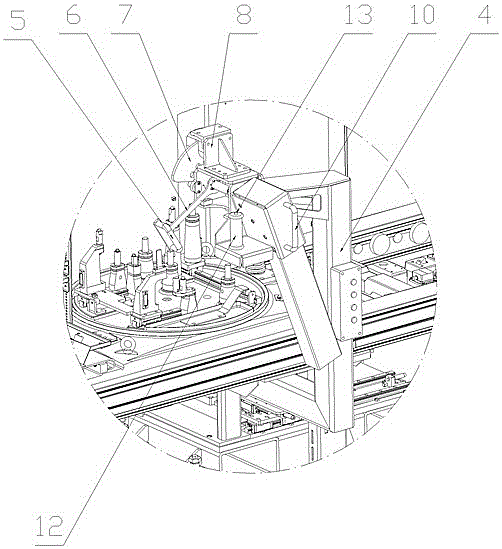

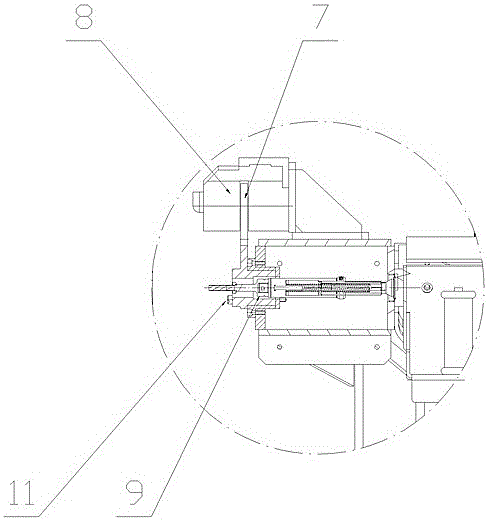

[0010] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 , image 3 Shown: a swing-type pneumatic clamping reaction arm mechanism, including a frame 2 fixed on the foundation ground, a roller table 1 is arranged on the frame 2, and a pallet 3 for transporting workpieces is provided matching the roller table 1 , a support frame 4 is fixedly arranged on the frame 2, and a swingable swing rod 6 is rotatably supported on the support frame 4. The end of the swing rod 6 is provided with a swing handle 5. When the swing rod 6 rotates, it can also drive a fan-shaped The disc 7 and the counter force arm tightening mechanism 9 rotate, and the fan-shaped disc 7 is provided with an air lock device 8, while the counter force arm tightening mechanism 9 is supported on the support frame 4 in an axially movable manner (the sector disc 7 and The reaction arm tightening mechanism 9 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com