Thin belt feed-in guide frame

A guide frame and thin material technology, which is applied in the direction of thin material processing, winding, transportation and packaging, etc., can solve the problems of difficulty in feeding and guiding thin material strips, and achieve the effect of reducing frictional resistance and avoiding frictional damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiments of the present invention will be comprehensively described below in conjunction with the drawings.

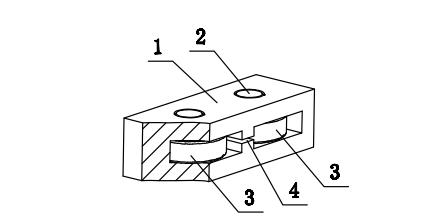

[0010] Such as figure 1 As shown, the guide frame 1 of the present invention is a rectangular parallelepiped block with a hole in the middle. The square holes on the left and right sides are put into the bearings 3, and the pin shaft 2 is positioned with the inner diameter of the inner ring. The distance is equal to the width of the strip 5; a slit 4 is opened between the square holes, and the thickness of the slit 4 is slightly larger than that of the strip 5. The strip material 5 is fed under the restriction of the slit 4, and its two sides are in contact with the outer ring of the bearing 3, which can effectively reduce the friction during travel and avoid friction damage.

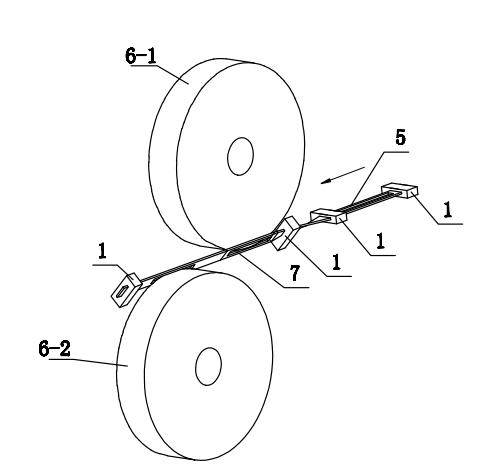

[0011] See figure 2 The polishing operation process working schematic of the polishing operation can better understand the working principle of the present invention. A numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com