Double-pressure direct-combustion reheating-type heating power output device

An output device and heat technology, which is applied in the field of high-efficiency recompression, direct-fired, and reheated heat output devices, can solve the problems of difficult maintenance, difficulty in quick and immediate use of heat energy, and large consumption of steel pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

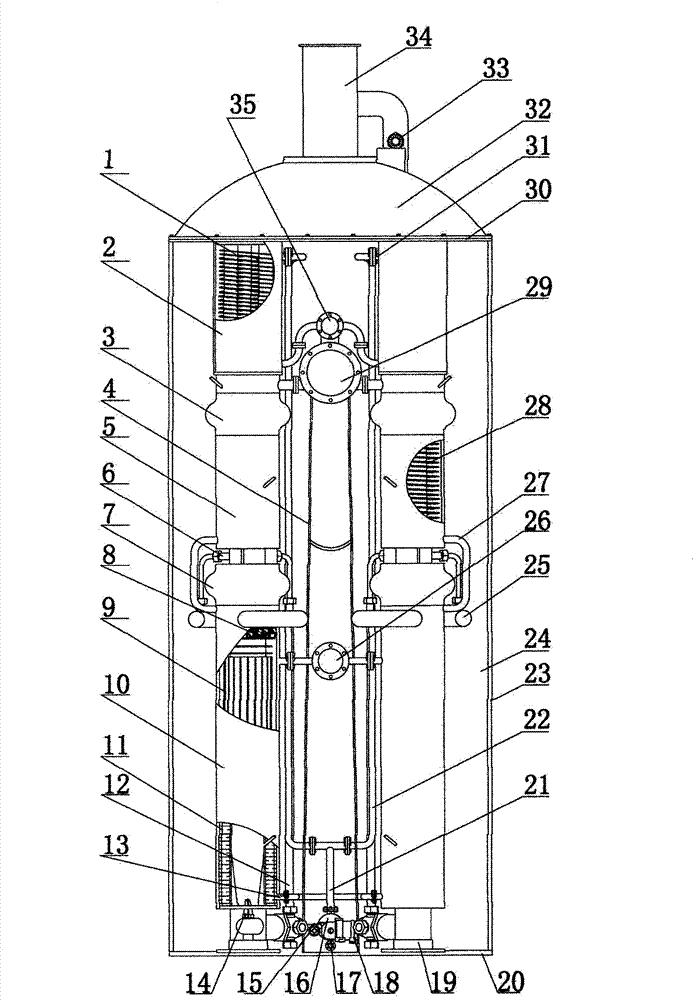

[0023] Such as figure 1 As shown, a recompressed direct-fired reheat heat output device according to an embodiment of the present invention includes a quick-acting energy replenishment linkage component, a boiling prevention steam-water separation component, a target superheating cogeneration component, a tail heat exchange recovery component, and a central intelligent control unit. appliances and accessories.

[0024]Among them, the quick-acting energy replenishment linkage assembly includes: burner A14, fuel main pipe inlet 17, fuel distributor 16, fuel branch pipe 12, waste heat recovery inlet 13, waste heat recovery branch pipe 22, waste heat recovery main pipe 21, high temperature working fluid pipe 26 , working fluid 11, heat exchange tube A9, heat exchange tube outer cylinder Ai0, working fluid pump 18, drain valve 15 and base 19. One end of the fuel main pipe is sealed and connected with the fuel distributor 16, and the other end is connected with the external fuel su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com