Collocation method of bicycle center shafting loss resistance

A configuration method and wear-resistant technology, which is applied to vehicle components, vehicle gearboxes, chain/belt transmissions, etc., to achieve the effect of easy modification, convenient disassembly, and simple configuration structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

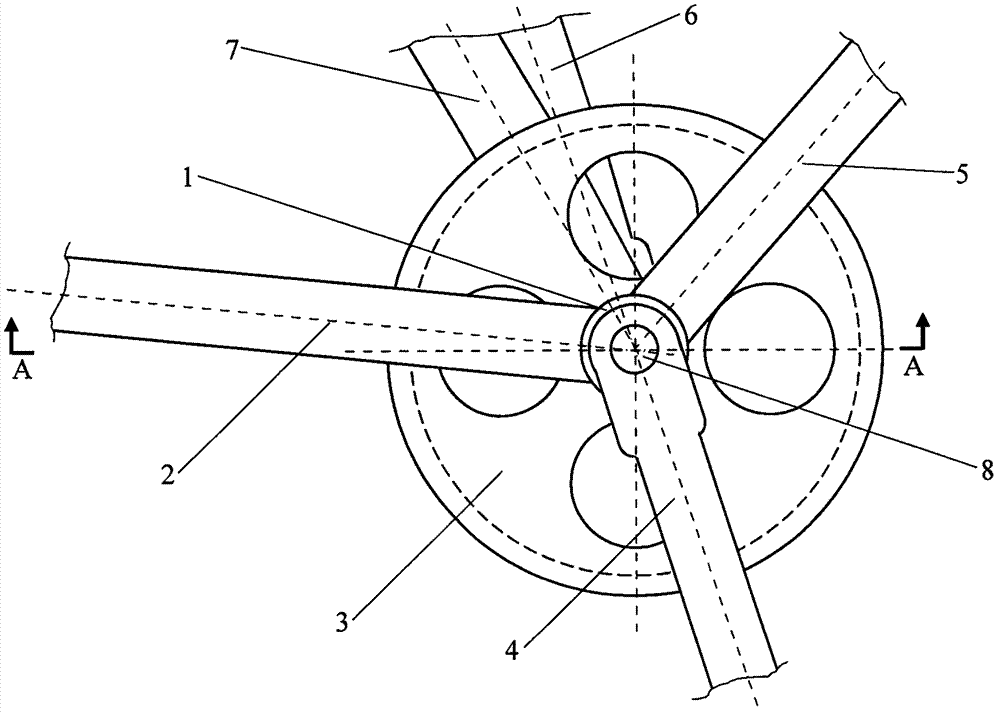

[0017] in the attached figure 1 , 2 In the shown structural view of the embodiment of the present invention: the cylindrical right bearing sleeve 1 is connected with the right end of the front fork of the rear fork beam 2 made into an "H" shape, and the right end of the lower fork of the front inclined beam 5 is connected as One body; the chain plate 3 is located between the right bearing housing 1 and the left bearing housing 9, and is a tight fit structure with the central shaft 8; the right crank 4 and the right end of the central shaft 8 are pin tight fit; the left crank 6 and the central shaft 8 The left end of the pin is a tight fit; the left end of the front fork of the "H" shaped rear fork beam 2, the left end of the lower fork of the front slant beam 5 and the lower end of the rear slant beam 7 are connected with the cylindrical left bearing seat sleeve 9 as one.

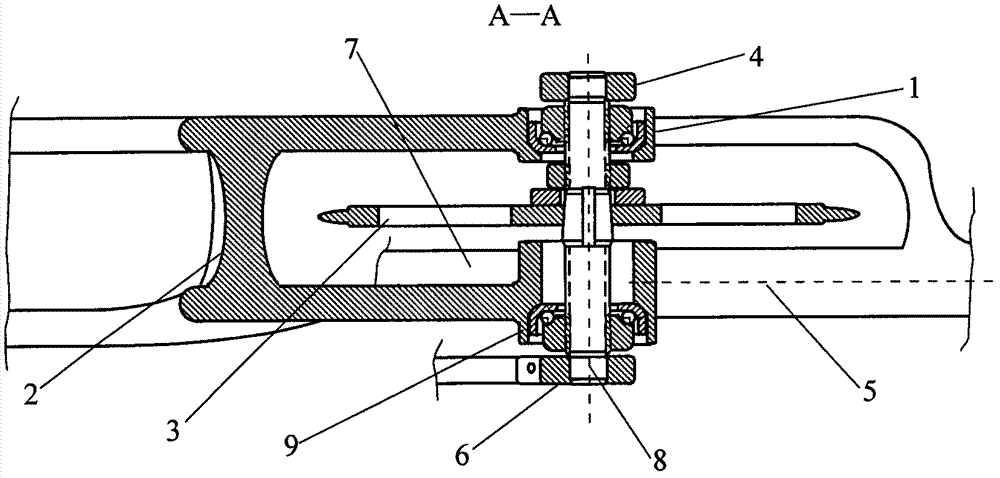

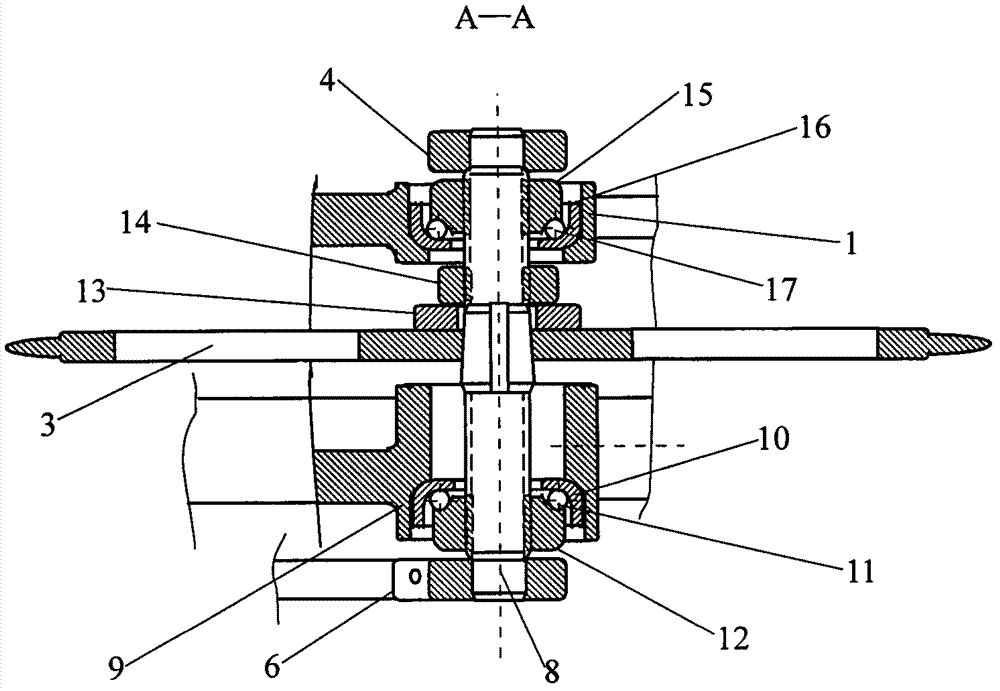

[0018] in the attached figure 2 , 3 In the shown cross-sectional view of the structure of the embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com