Fully integrated hydraulic clutch

A technology for clutches and pressure plates, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of high possibility of errors and complicated implementation, and achieve the effects of improving efficiency, avoiding conversion losses, and simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

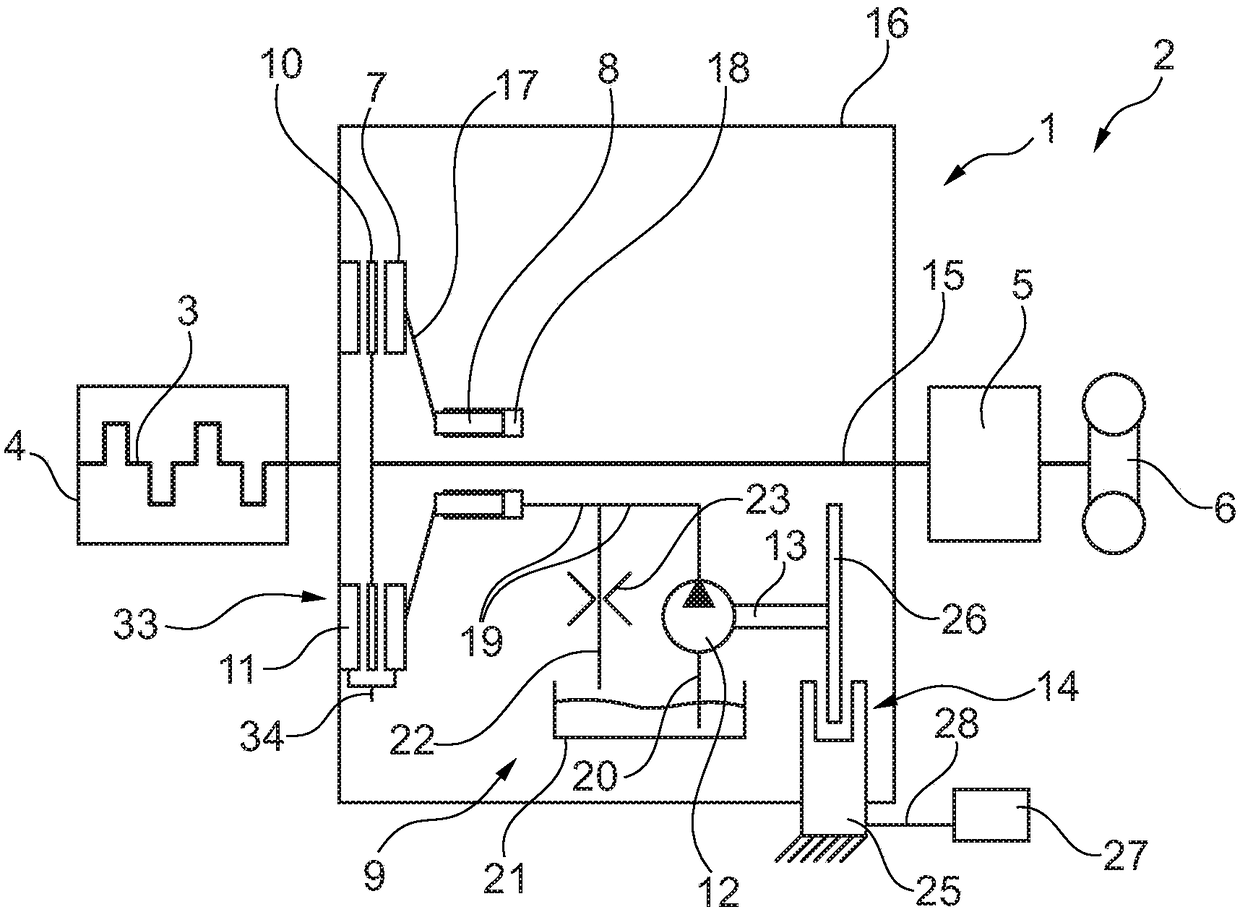

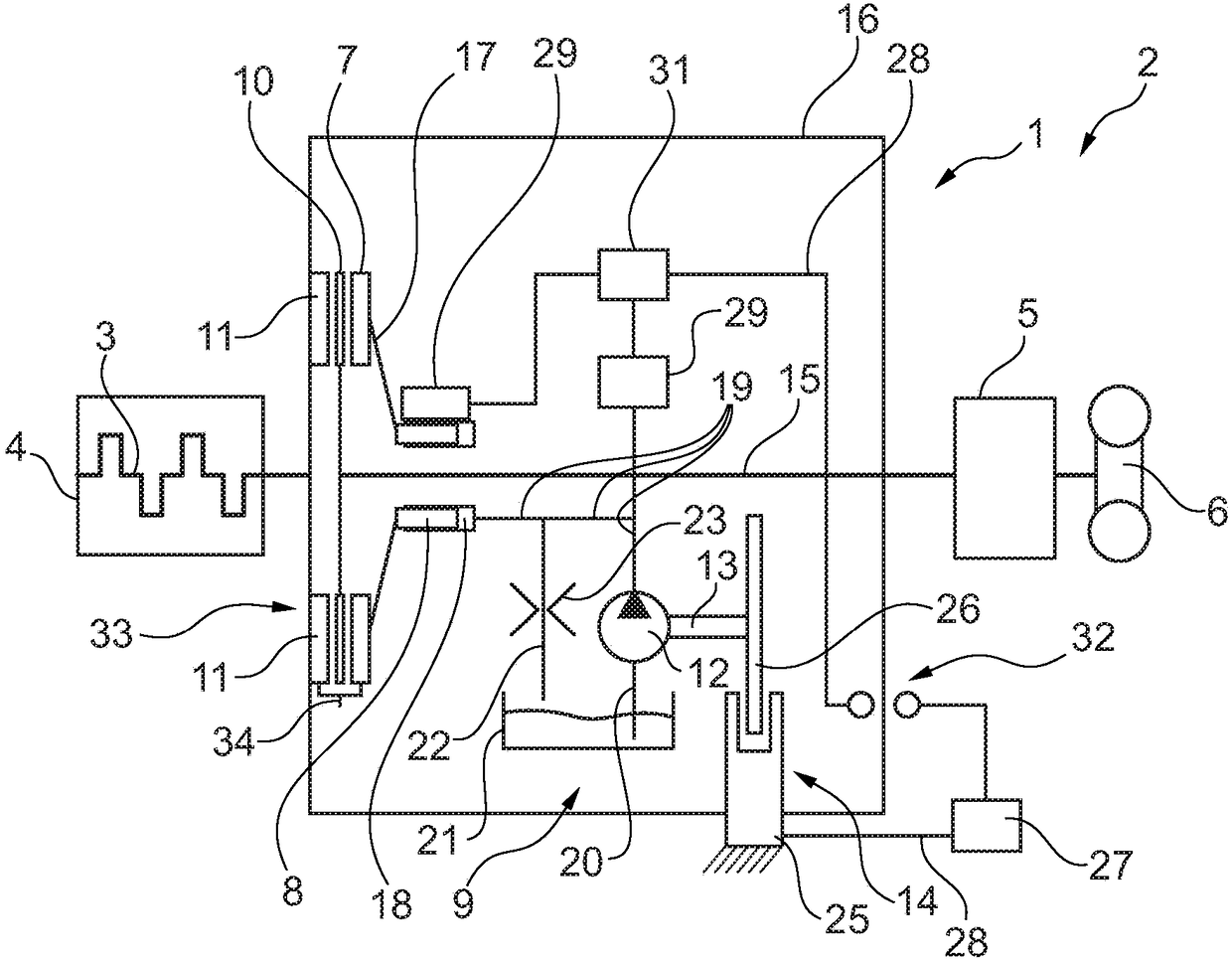

[0026] exist figure 1 with 2 Two embodiments of the clutch device 1 according to the invention are shown in . Each clutch device 1 is provided for incorporation into a drive train 2 of a motor vehicle, such as a passenger car, truck, bus or agricultural truck. The clutch device 1 serves as a detachable coupling element for the selective transmission of torque from a crankshaft 3 of an internal combustion engine 4 (diesel or petrol engine) to a transmission 5 which is connected to a wheel 6 or wheels of a motor vehicle. 6 motion coupling.

[0027] The clutch device 1 has a pressure plate 7 which is movable in the axial direction of the clutch device 1 (the axial direction corresponds to the direction along the clutch axis of rotation / rotation axis of the clutch). The pressure plate 7 here interacts / kinematically couples in the usual manner with the actuating piston 8 of the actuating device 9 . The pressure plate 7 can move back and forth between an actuated position (here ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com