Dynamic substitution regulating method for excessive bending of working roll of cold rolling mill

A technology of work roll bending and adjustment method, which is applied in the field of cold-rolled strip steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

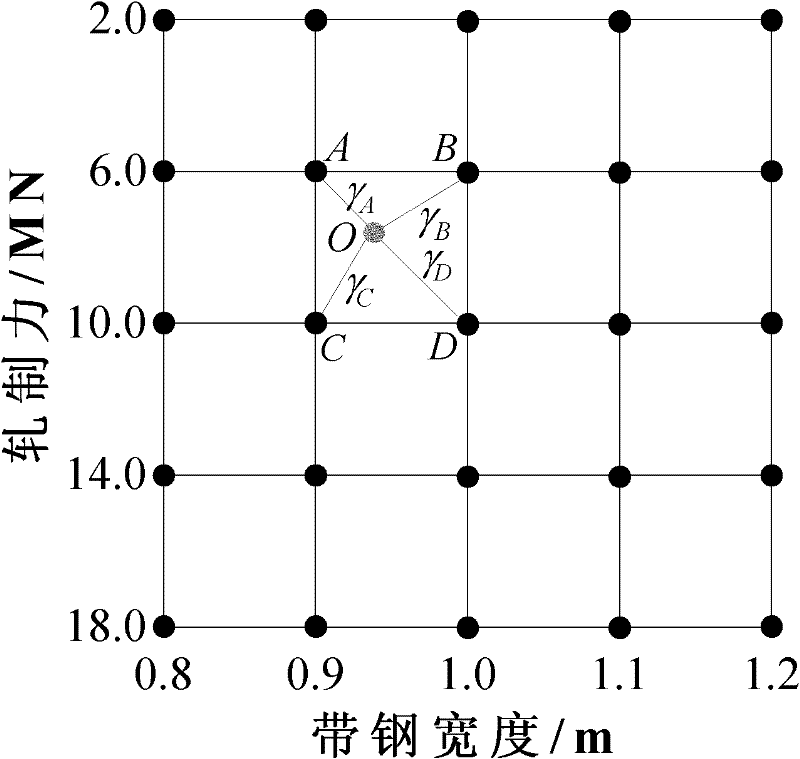

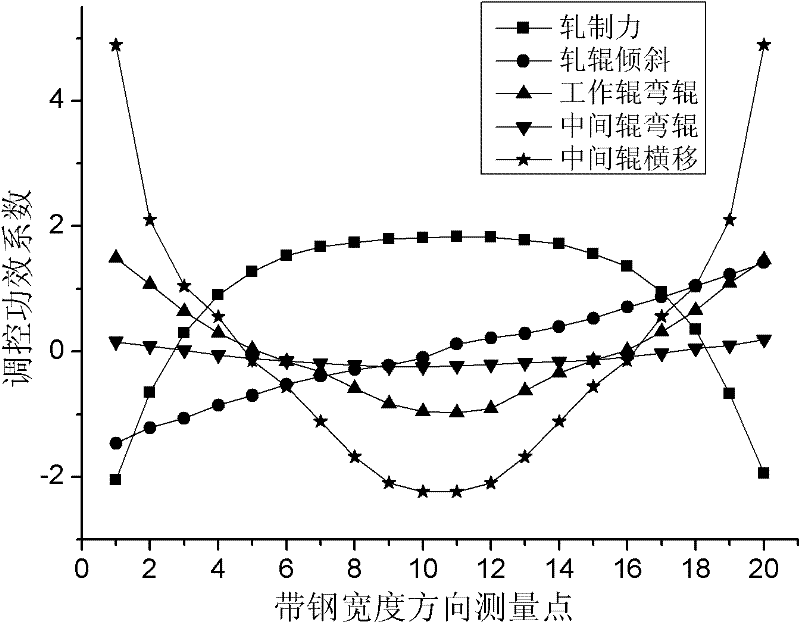

[0097] This embodiment discloses the dynamic adjustment processing process of the work roll bending overrun of a 1250 single-stand six-high reversing cold rolling mill. Taking the adjustment of the work roll positive roll overrun as an example, the replacement actuator is the intermediate roll bender. The control mode is the first one, and the final output of the intermediate roller does not exceed the limit. The shape adjustment mechanism includes roll tilting, positive / negative bending of work rolls, positive bending of intermediate rolls and lateral movement of intermediate rolls. The main control parameters and rolling parameters are shown in the table below.

[0098] Table 1 main parameters

[0099]

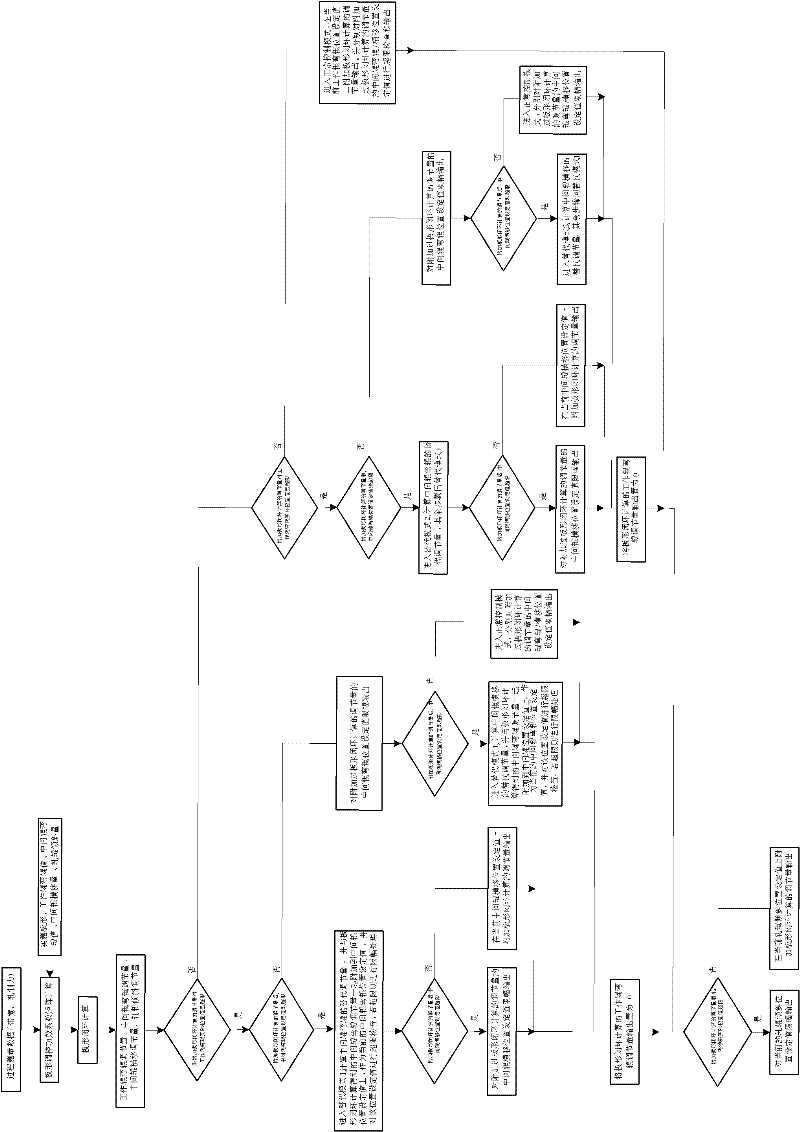

[0100] A dynamic alternative adjustment method for work roll bending overrun in a cold rolling mill, comprising the following steps: figure 2 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap