High-intensity sealed drum type rivet

A high-strength, drum-shaped technology, applied in the direction of rivets, can solve the problems of insufficient strength, damage to the riveted product, easy loosening and falling off, etc., and achieve the effect of high strength and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings.

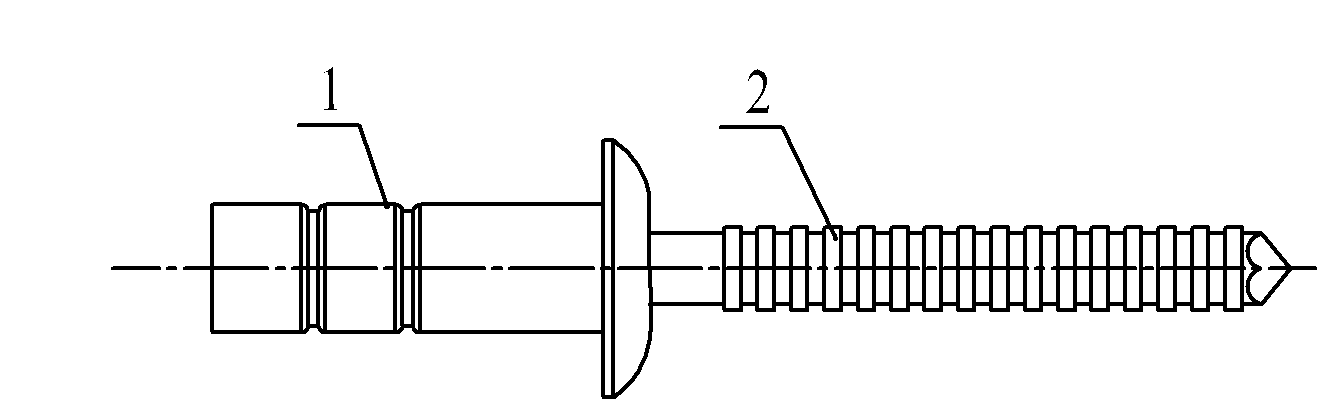

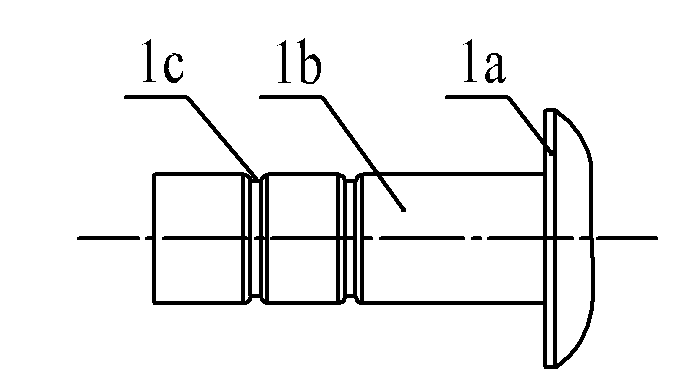

[0021] As shown in the figure, the high-strength closed drum rivet mainly consists of two parts: a nail body 1 and a nail core 2 . The nail body 1 is a hollow tubular body with one end open and the other closed. The nail core 2 is a solid structure, and the nail core 2 penetrates into the nail body 1 from the open end of the nail body 1 and is stuck without slipping. Out; one end of the opening of the nail body 1 is provided with a nail body head 1a, the outer diameter of the nail body head 1a is greater than the outer diameter of the nail body 1b, and the outer wall of the nail body 1b is provided with two parallel annular recesses Slot 1c.

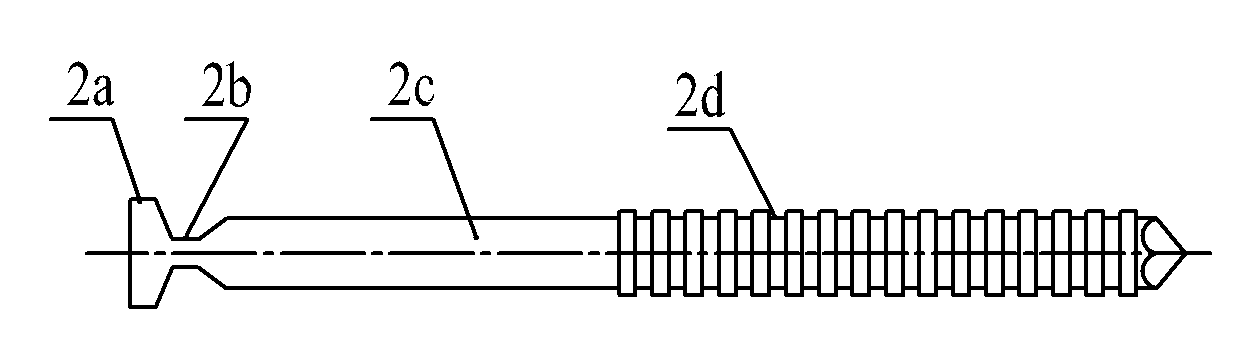

[0022] Such as Figure 4 As shown, in order to prevent the nail core 2 from slipping out in the nail body 1, the end of the nail core 2 is provided with a nail core head 2a, and the nail body 1 is provided with a Part 2a of the card p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com