Novel scouring-resistant thermal shock-resistant impact brick and preparation method thereof, and current stabilizer

A heat-resistant shock-resistant and scouring-resistant technology, used in manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of low overall strength of aluminum-magnesium-carbon bricks, multiple openings of impact bricks, and perforation of impact bricks. Achieve the effect of improving continuous flushing time, ensuring safe production and preventing perforation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

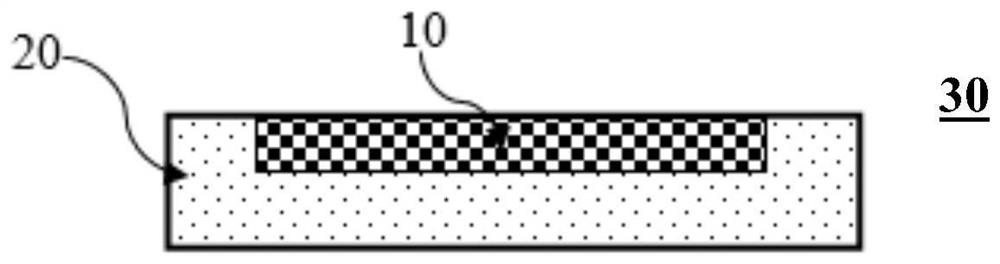

[0058] The preparation method of impact brick 30 comprises the steps:

[0059] S1: Mix 6 parts by mass of silicon metal powder, 2 parts by mass of aluminum metal powder, 8 parts by mass of silicon carbide, 50 parts by mass of dense corundum, and 20 parts by mass of aluminum-magnesium spinel, then add 5% phenolic resin, and mill at 500rpm for 20min Uniform, integrally stamped and formed on a 1200-ton press to obtain a stamped and formed plate with a size of 50cm*50cm*7cm; baked to 350°C and cooled for later use.

[0060] Among them, the median particle size of metal silicon powder is 30μm, the particle size of metal aluminum powder is 60-100 mesh; the particle size of silicon carbide fine powder is <0.074mm; the particle size of spinel is 150-250 mesh; -1mm.

[0061] S2: 40 parts by mass of waste corundum with a specification of 5-8mm, 10 parts by mass of waste corundum with a specification of 3-5mm, 10 parts by mass of waste corundum with a specification of 1-3mm, 10 parts by m...

preparation Embodiment 2

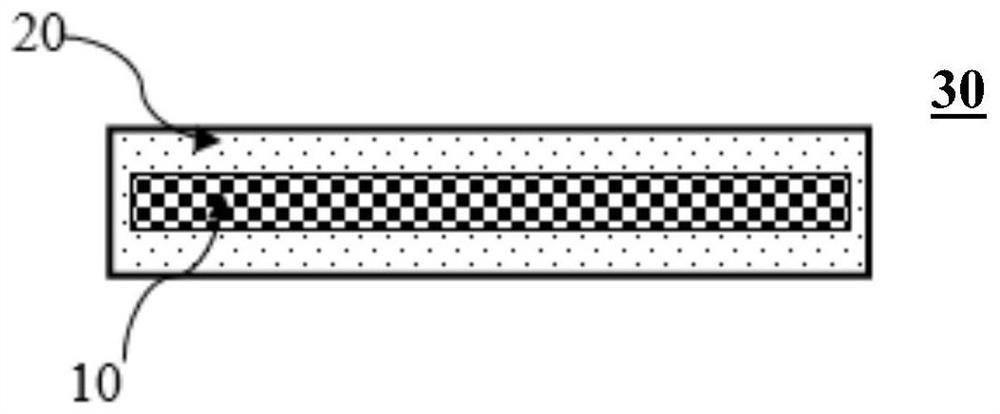

[0066] The preparation method of impact brick 30 comprises the steps:

[0067] S1: Mix 5 parts by mass of silicon metal powder, 3 parts by mass of aluminum metal powder, 10 parts by mass of silicon carbide, 60 parts by mass of dense corundum, and 25 parts by mass of aluminum-magnesium spinel, then add 6% phenolic resin, and mill at 500 rpm for 25 minutes Uniform, integrally stamped and formed on a 1200-ton press to obtain a stamped and formed plate with a size of 50cm*50cm*7cm; baked to 350°C and cooled for later use.

[0068] Among them, the median particle size of metal silicon powder is 40μm, the particle size of metal aluminum powder is 60-100 mesh; the particle size of silicon carbide fine powder is <0.074mm; the particle size of spinel is 150-250 mesh; -1mm.

[0069] S2: 45 parts by mass of waste corundum with a specification of 5-8mm, 12 parts by mass of waste corundum with a specification of 3-5mm, 12 parts by mass of waste corundum with a specification of 1-3mm, 8 pa...

preparation Embodiment 3

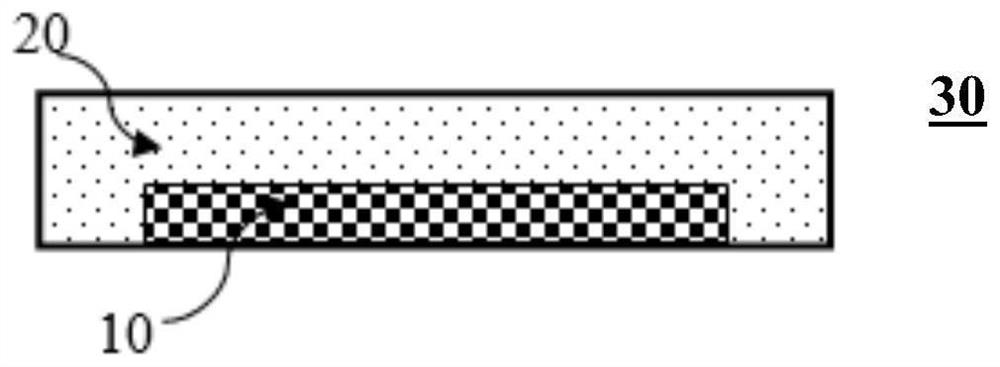

[0073] The preparation method of impact brick 30 comprises the steps:

[0074] S1: Mix 5 parts by mass of silicon metal powder, 1.5 parts by mass of aluminum metal powder, 10 parts by mass of silicon carbide, 47 parts by mass of dense corundum, and 25 parts by mass of aluminum-magnesium spinel, then add 5% phenolic resin, and ball mill at 500rpm for 25min Uniform, integrally stamped and formed on a 1200-ton press to obtain a stamped and formed plate with a size of 50cm*50cm*7cm; baked to 350°C and cooled for later use.

[0075] The processing conditions of steps S2-S5 are the same as those of the preparation and implementation two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com