Titanium alloy folding shockproof rivet

A titanium alloy, folding technology, applied in rivets and other directions, can solve problems such as easy corrosion, damage to riveted products, affecting product quality and performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

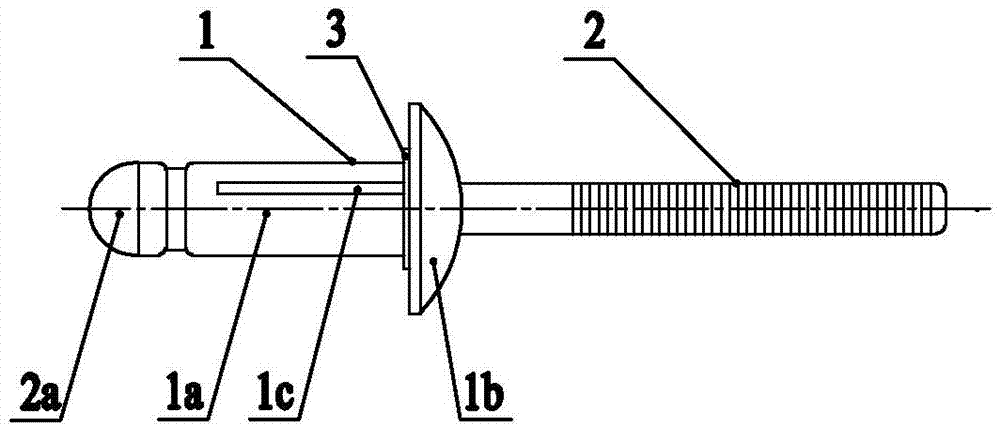

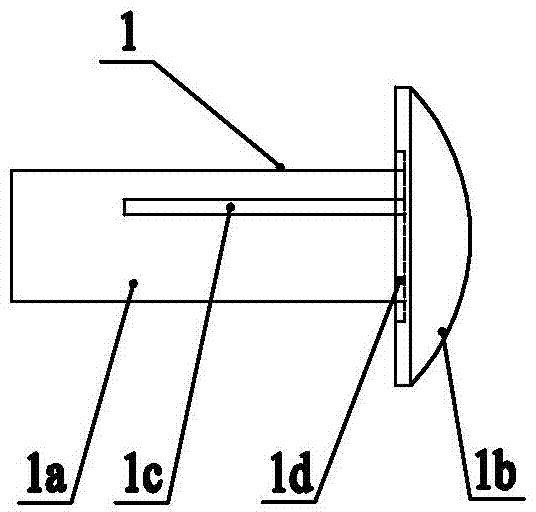

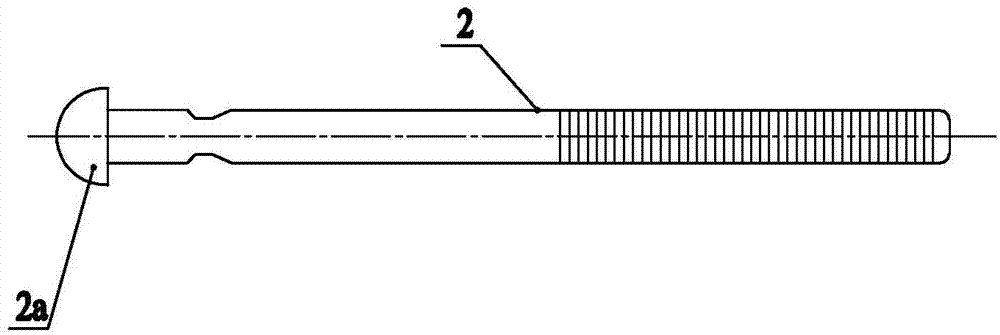

[0020] Such as Figure 1~Figure 3 As shown: the titanium alloy folding anti-vibration rivet in the embodiment is mainly composed of a nail body 1 and a nail core 2; the nail body 1 is a hollow tubular body, and the nail core 2 can be a conventional nail core 2. One end of the core 2 is processed with a nail head 2a, and the other end of the nail core 2 penetrates the nail body 1 from the tail end of the nail body 1 and stretches out from the nail body head 1b; the nail body 1 includes the nail body 1a and Nail body head 1b, the outer diameter of nail body head 1b is greater than the outer diameter of nail body 1a, and the outer wall of nail body 1a is provided with three vertical through grooves 1c uniformly distributed along the circumferential direction, and described longitudinal through groove 1c is formed from nail body 1a. The bottom surface of the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com