Wire-to-board connector

A technology of wire-to-board connectors and wire ends, which is applied in the direction of connection, fixed connection, and parts of the connection device. It can solve the problems of long assembly process, difficulty in improving efficiency, and insufficient convenience and flexibility, and achieve simple riveting operations. Overall volume miniaturization, convenience and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the structural features and advantages of the wire-to-board connector of the present invention more clearly understood, it will be described in detail below with reference to the accompanying drawings.

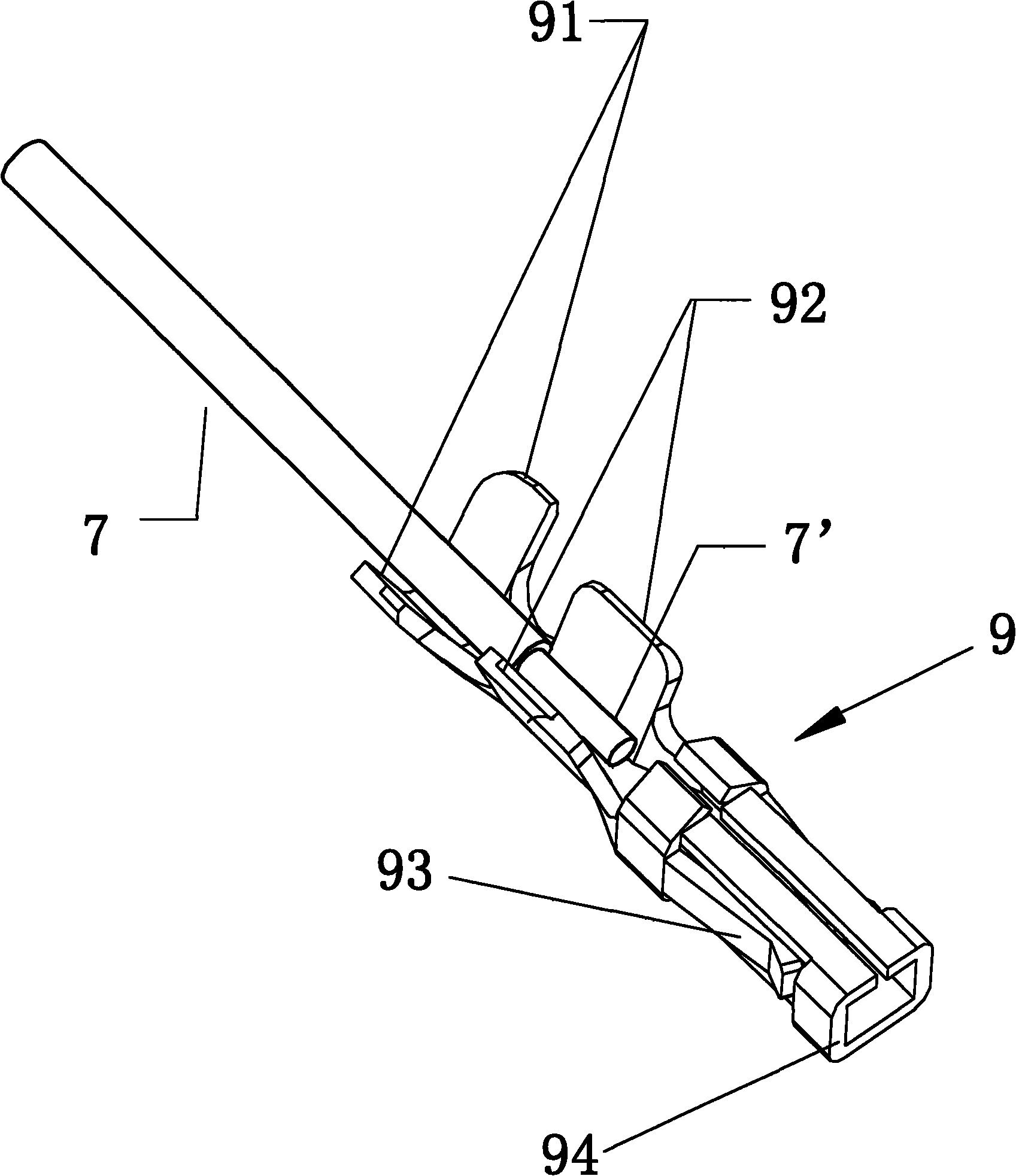

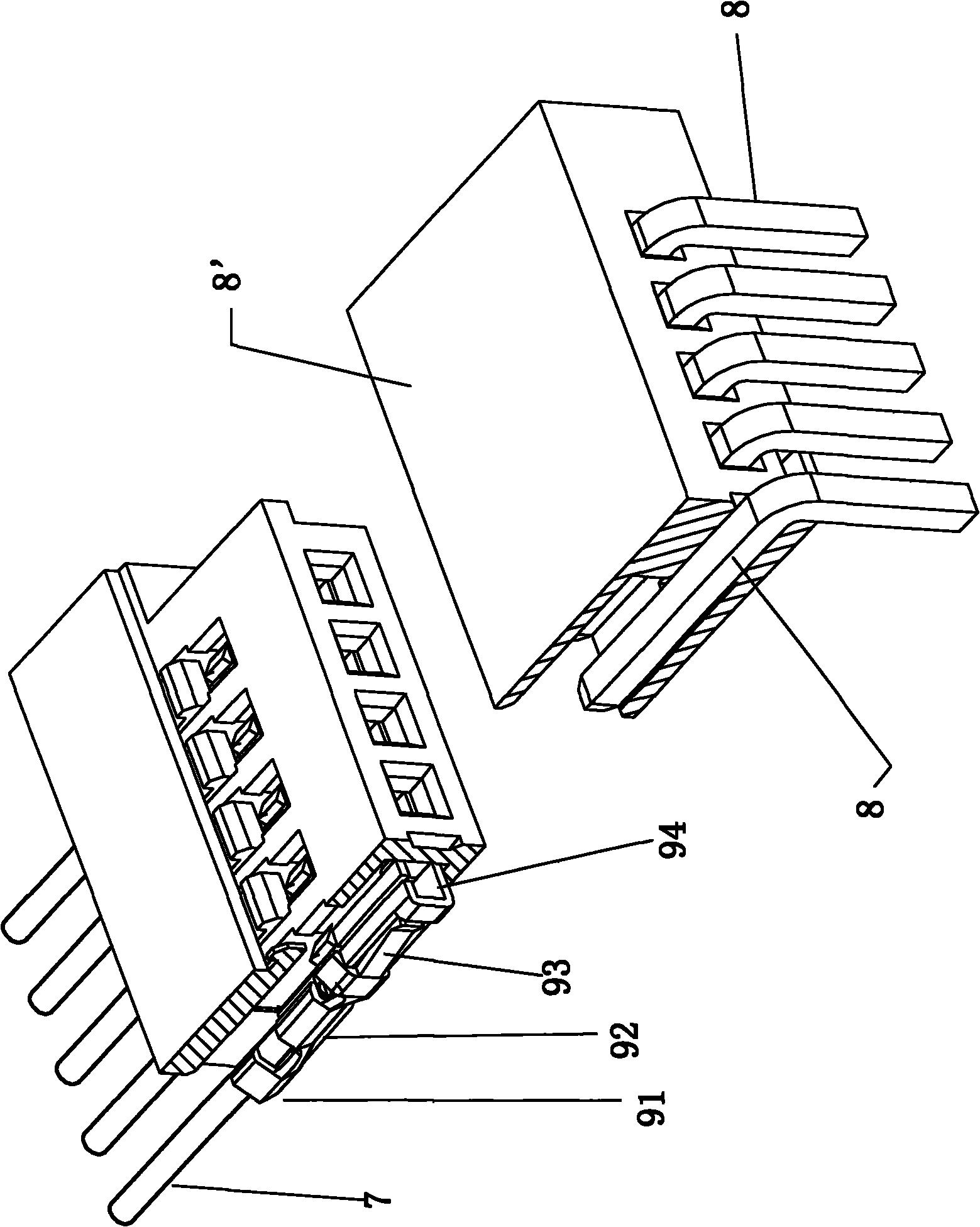

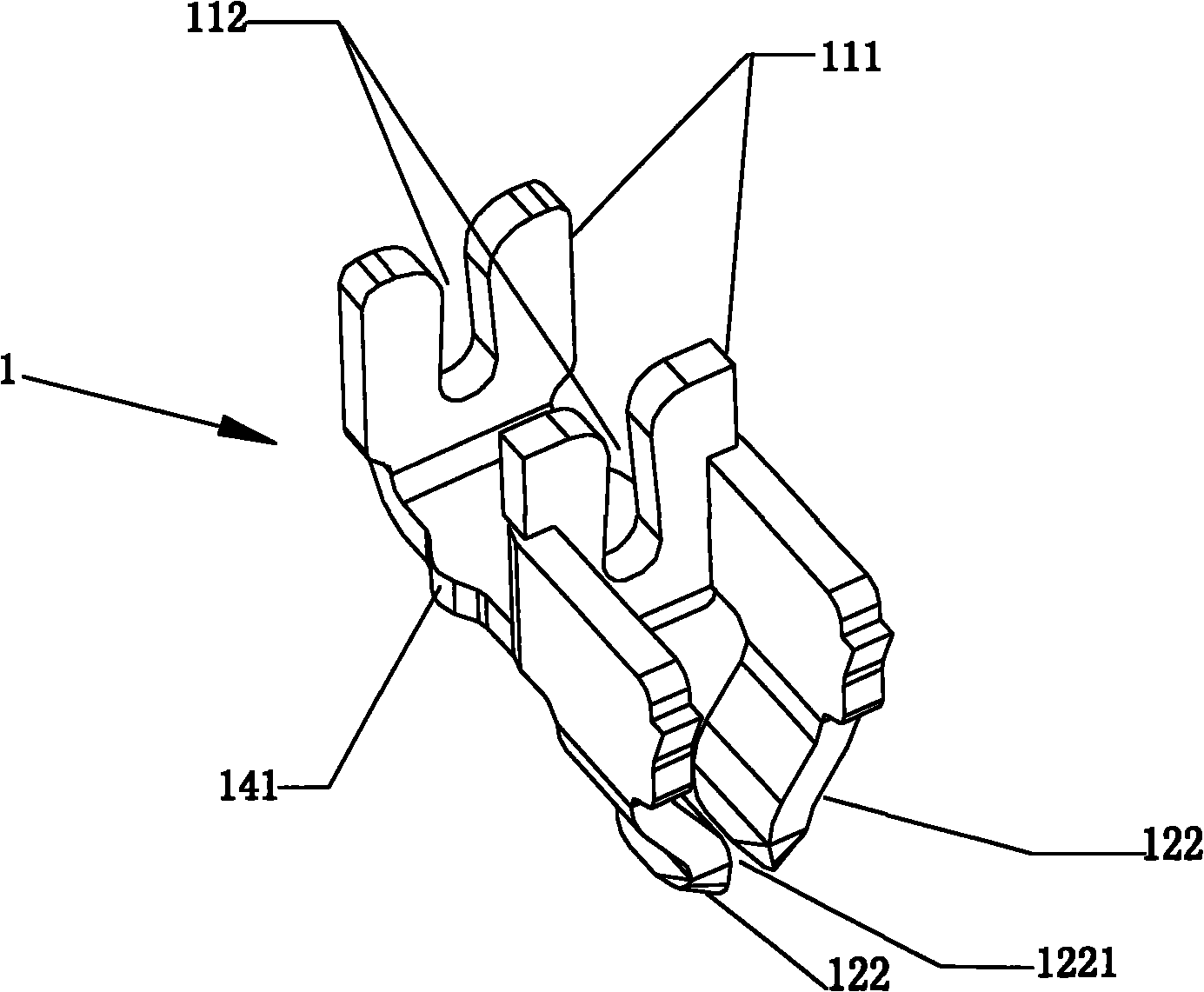

[0030] Such as image 3 As shown, the wire-to-board connector of the present invention includes a wire-end connector 10 composed of several wire-end terminals 1 and a plastic body 2 . Each wire terminal 1 has a terminal, a fixing portion and a contact portion respectively. The connection terminal is the part where the wire end terminal 1 and the wire form a reliable conductive connection. It is counted as a thin wire clamp 111. A slit 112 is formed in the middle of the wire clamp 111. The upper part of the slit 112 is an opening. The metal sheet of the plate 111 is very thin, and the distance between the thin slits 112 is very small. When the wire rod is pressed down from the top of the thin slit 112, the thin slit 112 can easily cut the rubber outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com