Low return difference structure for vertical rotor gas solenoid valve

A gas solenoid valve, rotor type technology, applied in the valve operation/release device, valve details, valve device and other directions, can solve the problems of large backlash, large action displacement backlash, etc., to achieve low gas regulation, eliminate gas leakage The effect of reducing the hysteresis difference between gas and movement displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is described in further detail by the following examples.

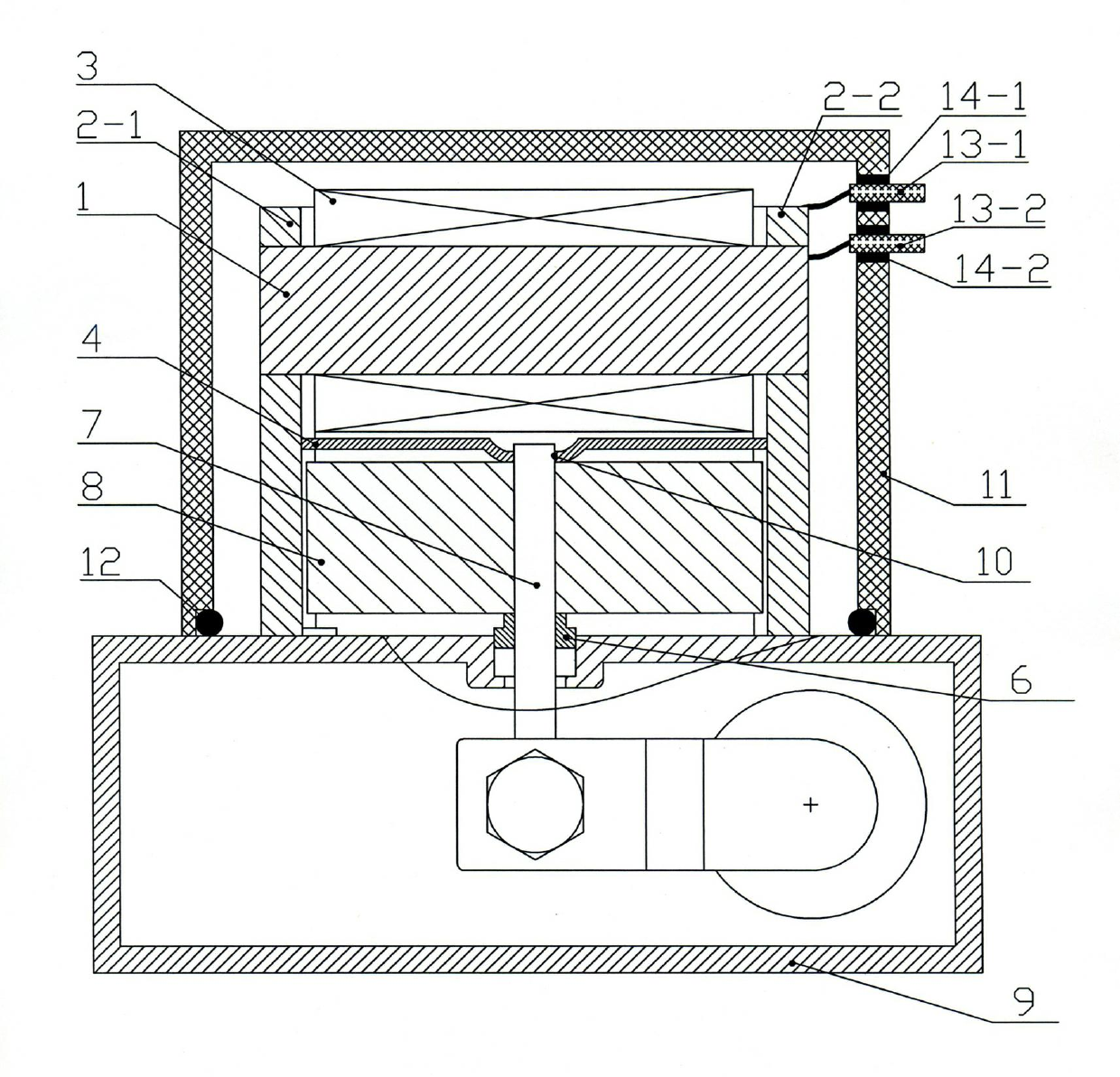

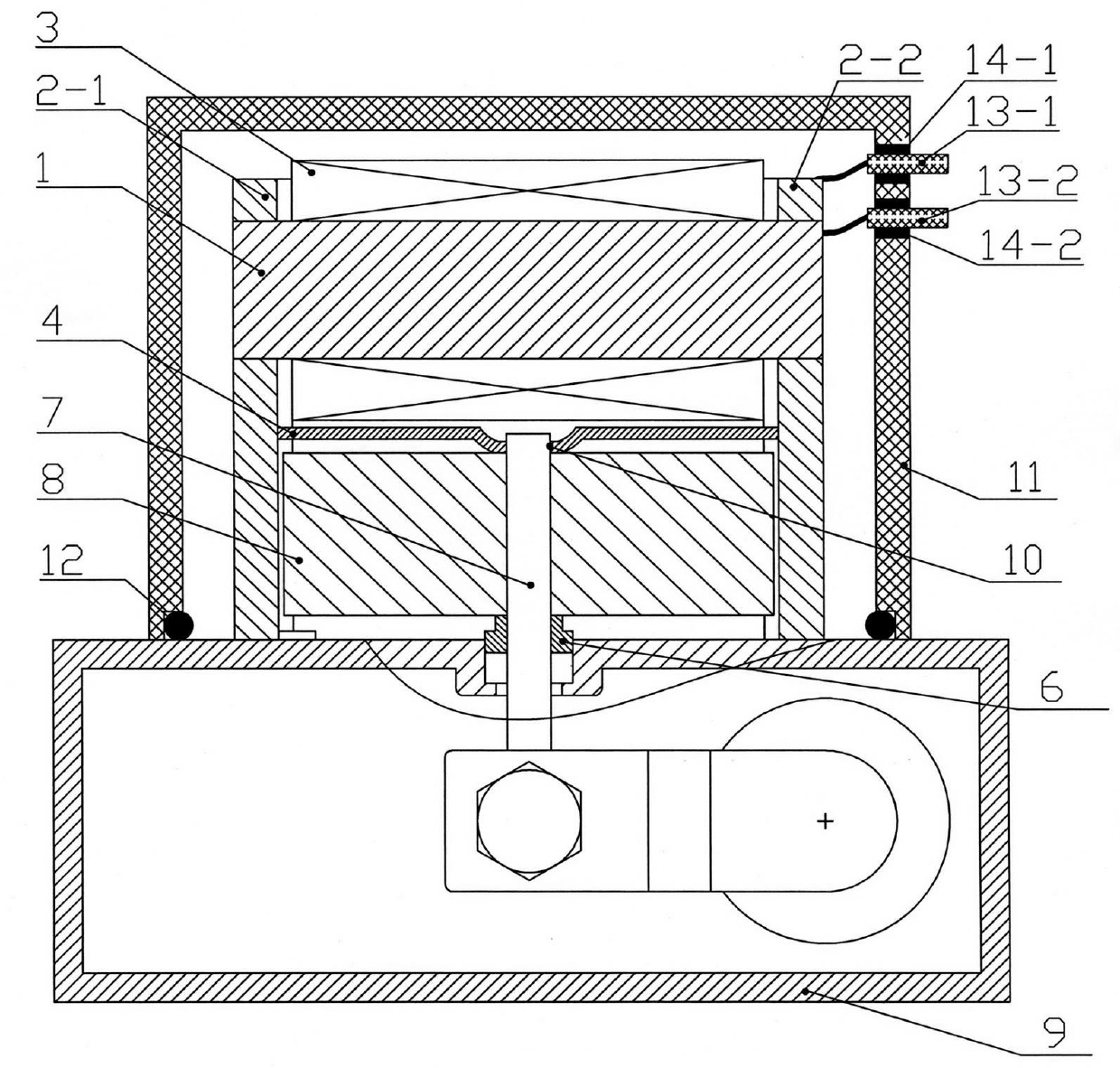

[0010] refer to figure 1 As shown, a vertical rotor solenoid valve with low hysteresis structure consists of stator core 1, stator coil winding 3, stator side pieces 2-1, 2-2, upper rotor fixed piece 4, rotor shaft 7, and rotor 8 The vertical rotor electromagnet composed of the rotor adjustment mechanism is located outside the valve casing 9, the valve casing 9 is provided with an air inlet, an air outlet and a valve port, the rotor shaft 7 is movably connected with the valve casing 9 through the bearing 6, and the rotor shaft 7 The upper end is movably connected with the shaft hole 10 of the upper rotor fixed piece 4, there is no leak-proof cover 11 between the periphery of the vertical rotor electromagnet and the valve housing 9, and a rubber seal is installed between the leak-proof cover 11 and the valve housing 9 Ring 12, connecting terminals 13-1, 13-2 are installed on the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com