Magnetic drive high speed turbocharger

A technology of turbocharger and magnetic transmission, which is applied in the direction of machines/engines, electromechanical transmissions, liquid fuel engines, etc. It can solve the problems of difficult sealing and gas transportation, and achieve the effect of eliminating gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention is not limited to the scope described in the embodiments.

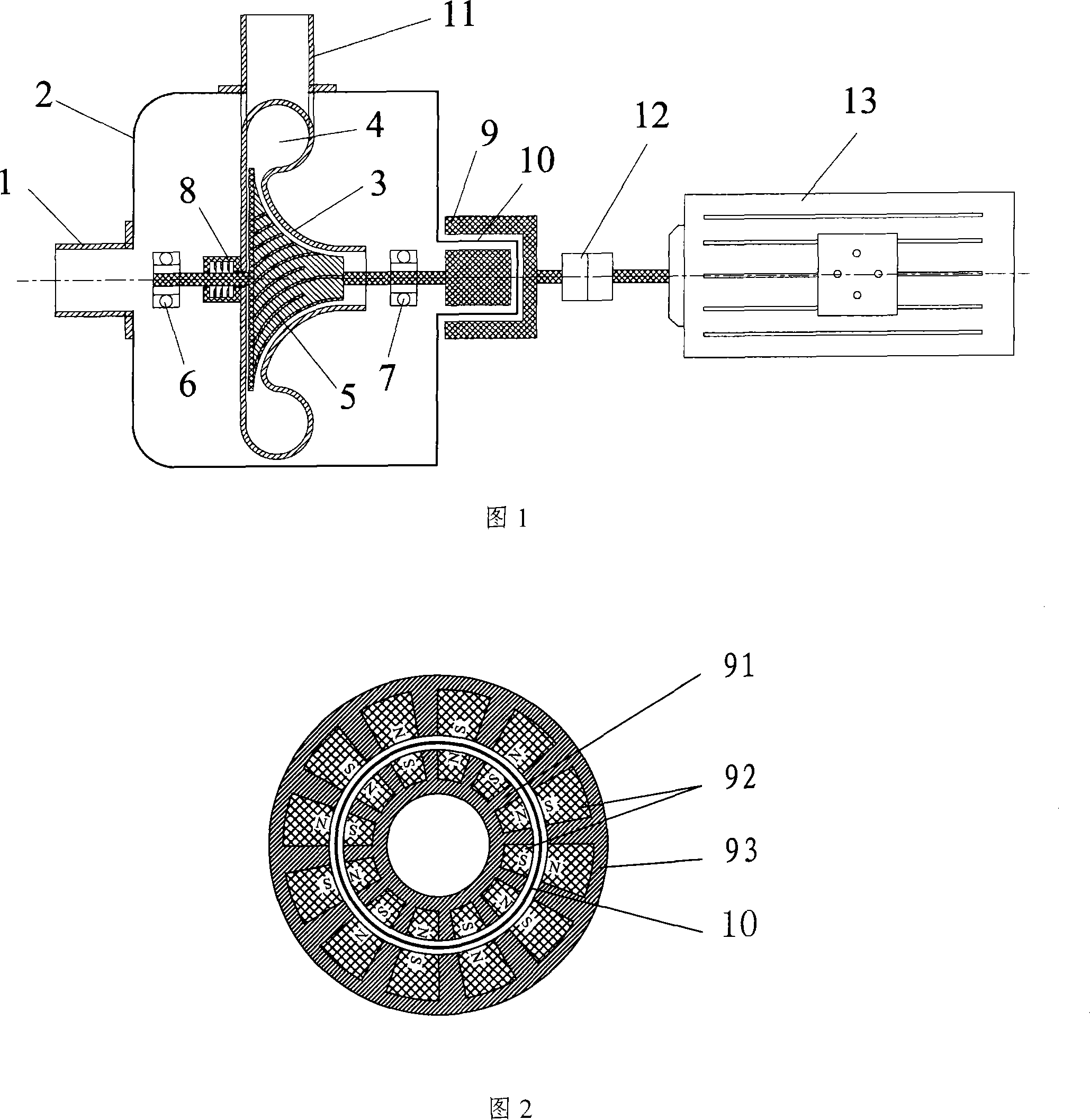

[0020] As shown in Figure 1, a magnetic drive high-speed turbocharger includes a volute 3, a turbine rotor 5, a diffuser tank 4, a housing 2, an air outlet 11, a high-speed motor 13 and a magnetic coupling 9, and the turbine rotor 5 is located at The center of the volute 3, the outer side of the turbine rotor 5 in the volute 3 is a diffuser groove 4, the diffuser groove 4 communicates with the air outlet 11, the volute 3, the turbine rotor 5, and the diffuser groove 4 are arranged in the housing 1, and the housing The body 2 is provided with an air inlet 1 and an air outlet 11. The magnetic coupling 9 is composed of an outer rotor assembly and an inner rotor assembly. The outer rotor assembly and the inner rotor assembly are separated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com