On-site measuring apparatus for local mechanical properties of materials

An on-site measurement and mechanical technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of heavy equipment, large geometric measurement errors, inconvenient installation, etc., and achieve the effect of reducing contact friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

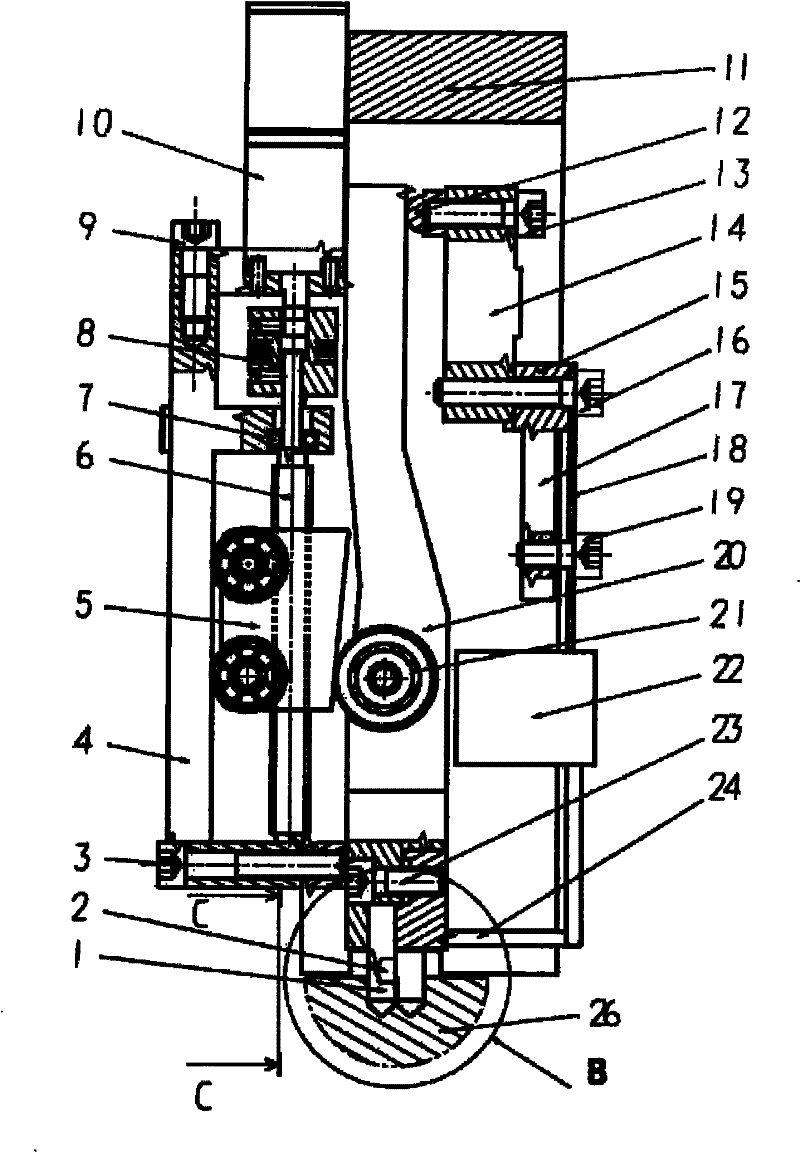

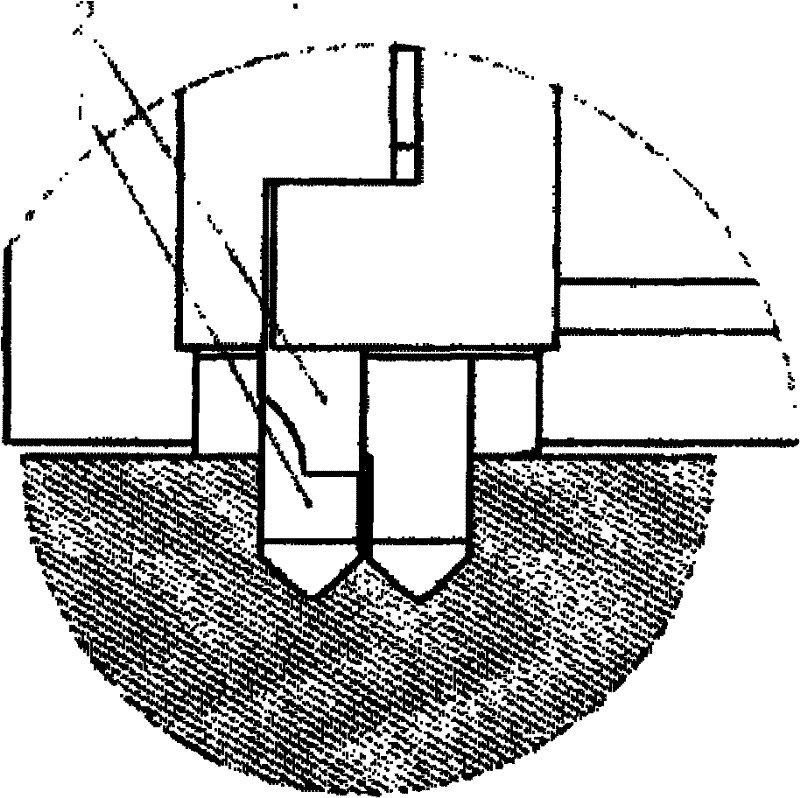

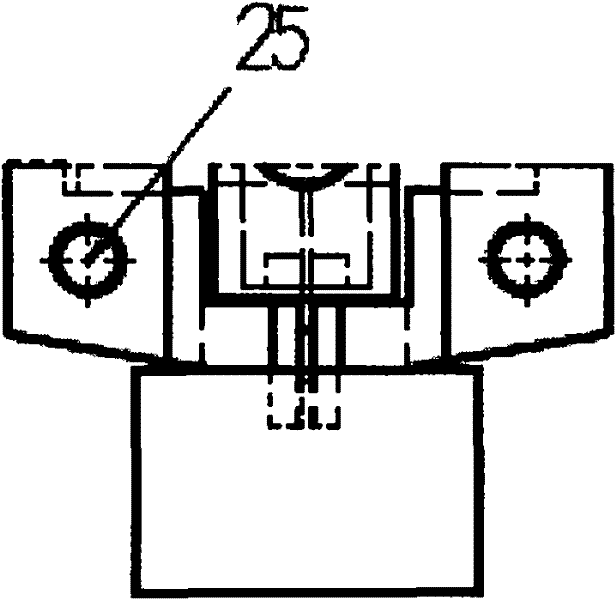

[0012] like figure 1 , figure 2 , image 3 As shown, the device of the present invention is composed of a driving loading shear unit, a device fixing unit, a displacement detection unit, and a load detection unit. The driving loading shear unit, the device fixing unit, the displacement detection unit and the load detection unit are all installed on a U-shaped On the groove 11, the screw rod 6 in the driving loading and shearing unit is installed on the bracket 4 through the first bearings 7 at both ends, and the DC motor 10 is fixed on the bracket 4 through two M6 inner hexagon bolts 9, and is connected by a coupling 8 is connected with the screw mandrel 6, the slider 5 with rollers is installed on the screw mandrel 6, the swing rod 20 can swing in the U-shaped groove 11, and the second bearing 21 in the middle is in contact with the slope of the slider 5 with rollers, The indenter 2 is made of hard alloy with a thickness of 1±0.1mm. It is fastened to one end of the swing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com