Efficient residual pumping light attenuation method

A pumping light and pumping technology, which is applied in the coupling of lasers, laser components, and optical waveguides, can solve the problems of easily damaged absorbing materials and long absorption lengths, and achieve the effect of meeting blocking requirements and short attenuation lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

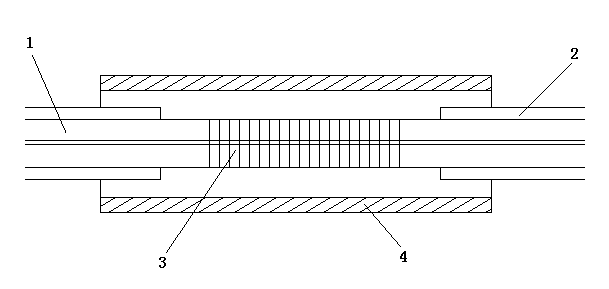

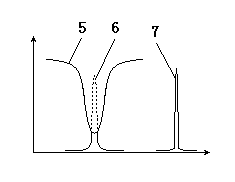

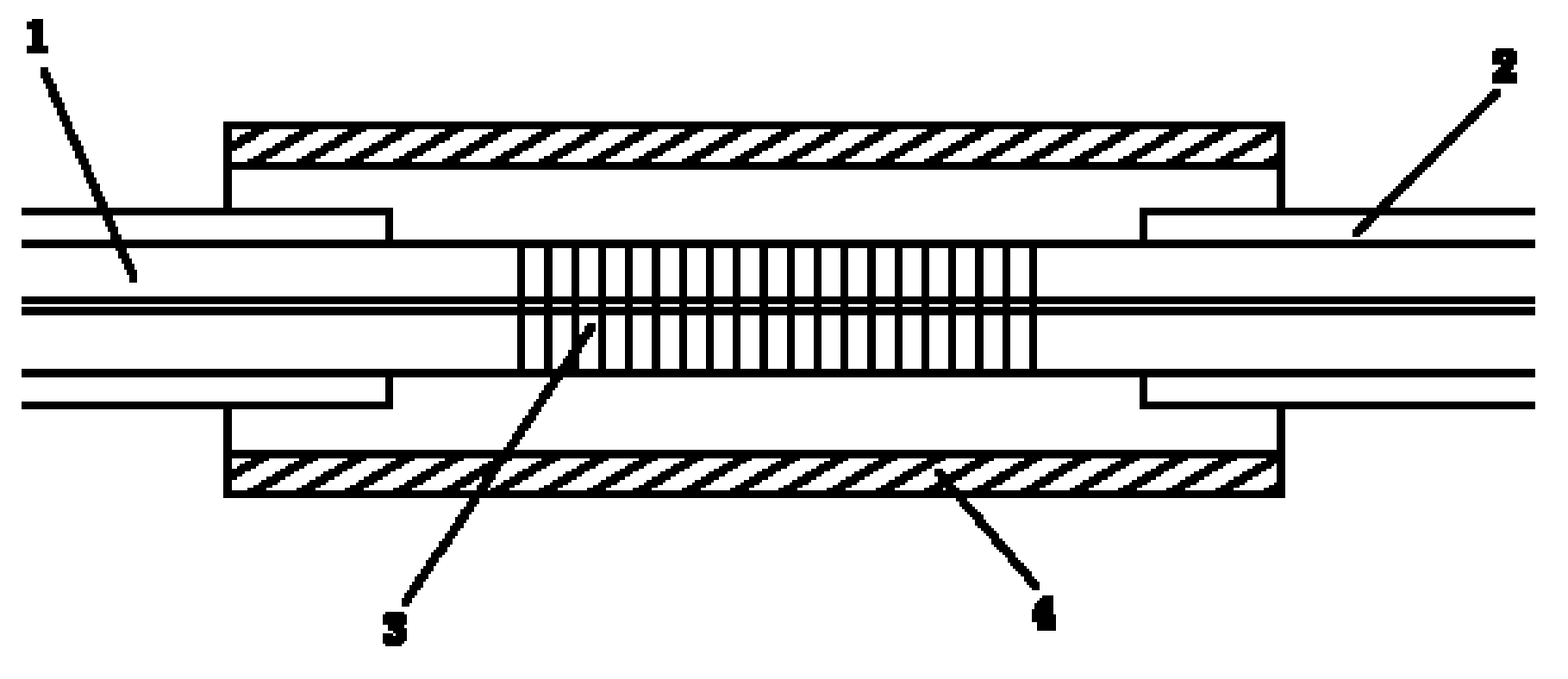

[0011] Remove the outer cladding 2 with a length L of 5 mm to 50 mm at the pump end of the double-clad fiber 1 where the remaining pumping needs to be leaked, and fabricate a long-period fiber grating 3 with a length L1 in the middle of the fiber section from which the outer cladding is removed. The value should be such that the distance between the two ends of the grating 3 and the outer cladding 2 is not less than 2mm, and at the same time, the attenuation value of the grating 3 meets the requirements of the remaining pump leakage, and its value is between 5dB~30dB. 5 Matches the pump spectrum curve 6 and does not attenuate the signal light 7 of the fiber laser. In order to prevent the leaked remaining pump light from damaging other components, the outer cladding fiber section is removed, and the surface with light absorption and heat dissipation is blackened. The metal sleeve 4 shields the leakage of the remaining pump light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com