Forging and pressing punch head overload protection device and forging and pressing device with same

An overload protection and protection device technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problems of reduced utilization rate, low punch, large volume, etc., to achieve The effect of reducing mold cost, improving mass production, and reducing tolerance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

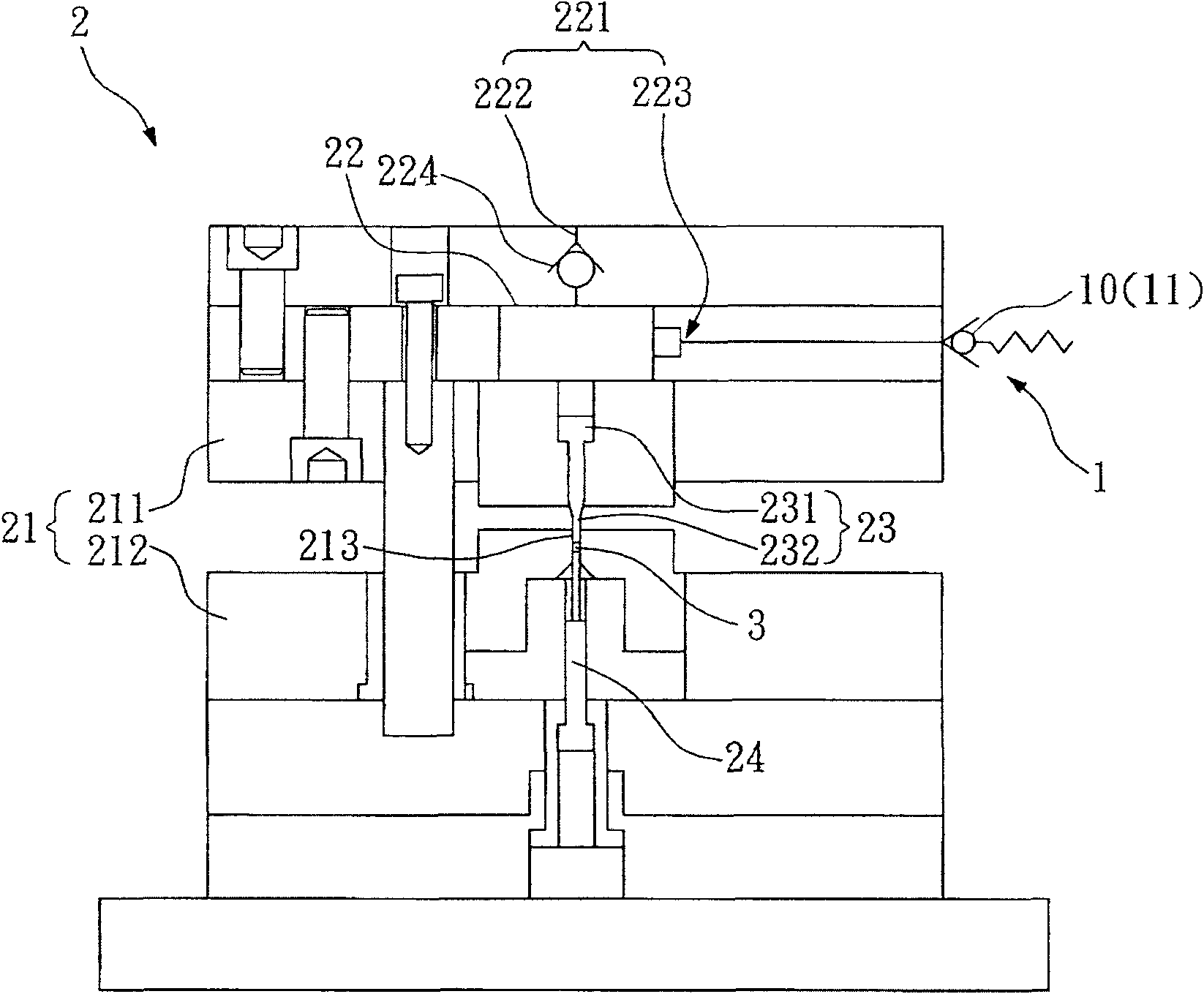

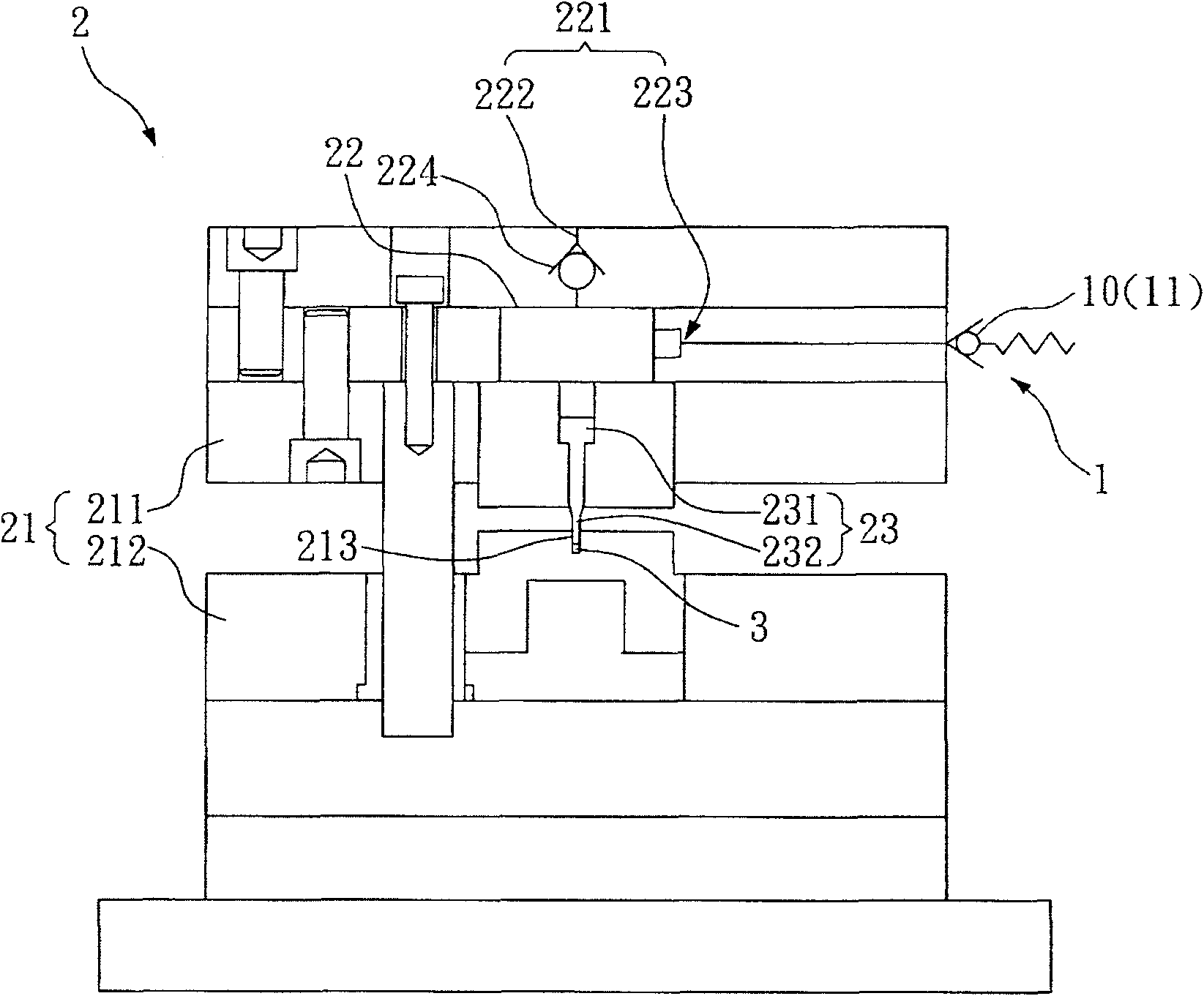

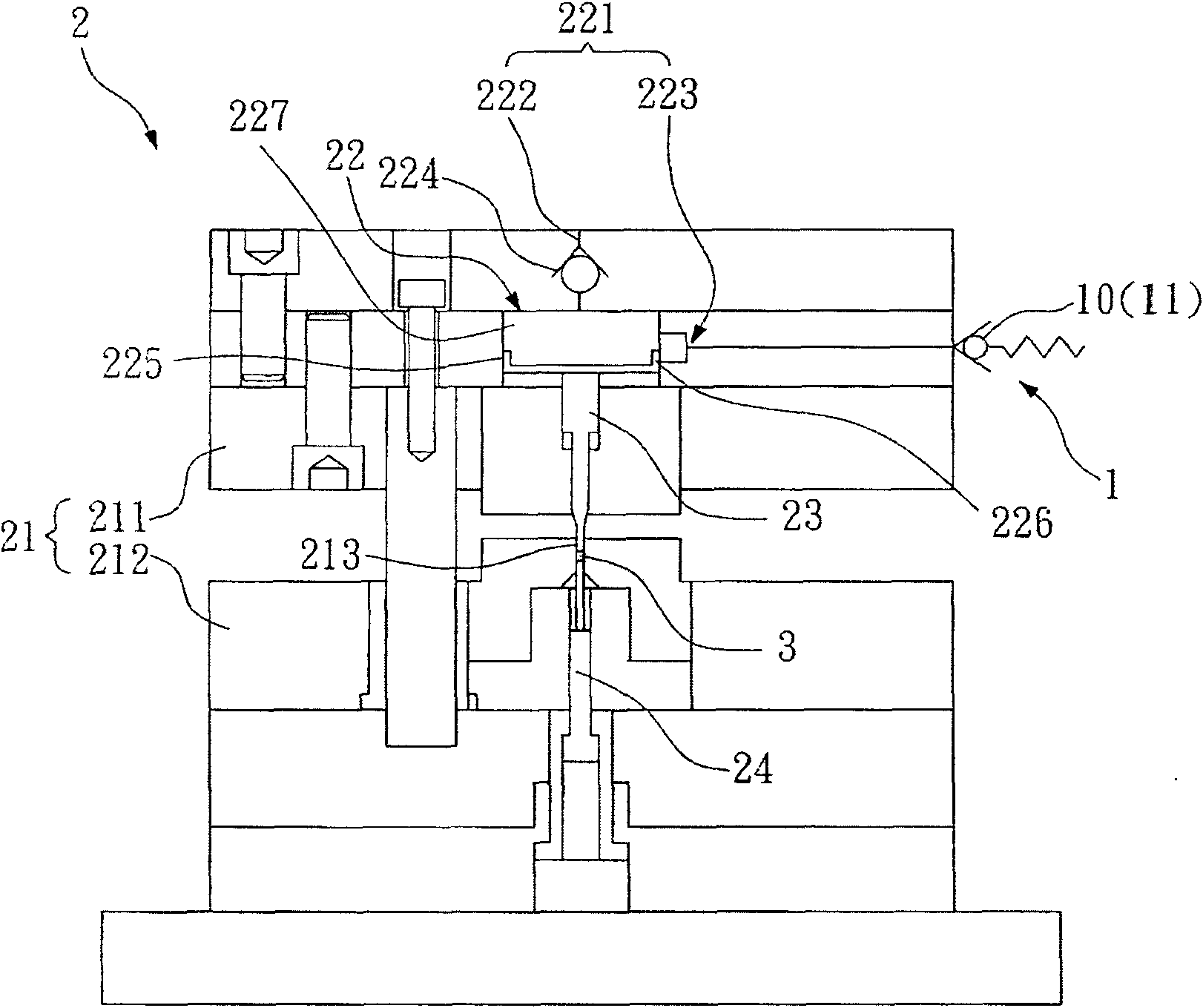

[0060] refer to figure 1 , which shows a schematic diagram of the forging punch overload protection device according to the first embodiment of the present invention. The forging punch overload protection device 1 can be applied to a die or a forging die, and can also be applied to a fine forging process or a micro-closed forging process for the manufacture of fine components (eg, micro gears with a size of 1-3 mm). The forging punch overload protection device 1 is connected with a forging device 2 , and the forging device 2 includes a mold 21 , a fluid pressure cavity 22 and a punch 23 .

[0061]In this embodiment, the mold 21 has an upper mold 211 and a lower mold 212, the fluid pressure cavity 22 is set on the upper mold 211,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com