Preparation method of high-density graphene thermally conductive film

A graphene, high-density technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of uneven appearance, high pressure, and high cost of graphene production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

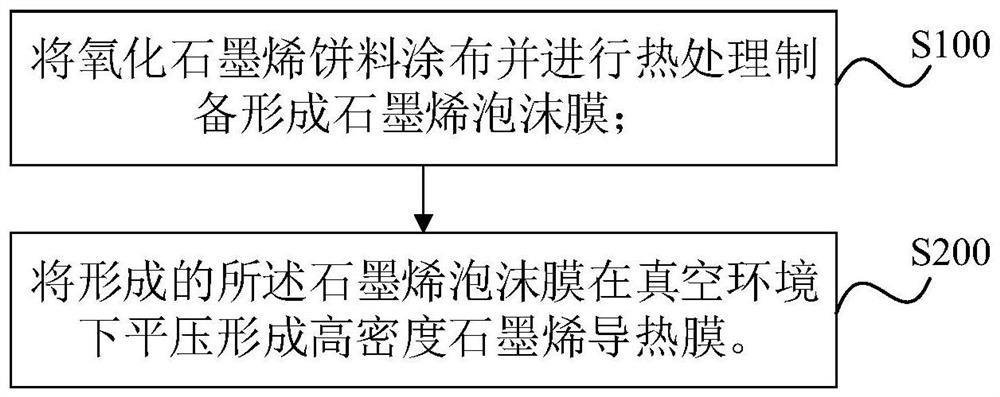

[0020] see in combination figure 1 As shown, according to an embodiment of the present invention, a preparation method of a high-density graphene thermally conductive film is provided, comprising the following steps:

[0021] S100, the graphene oxide cake is coated and heat-treated to prepare a graphene foam film;

[0022] S200, flat pressing the formed graphene foam film in a vacuum environment to form a high-density graphene thermal conductive film.

[0023] The technical solution flattens the graphene foam film in a vacuum environment without excessive pressure, and can flatten multiple graphene foam films at a time to form a graphene thermal conductive film with high density and uniform appearance, which improves the graphene performance. The yield of thermally conductive film and the mass production of graphene thermally conductive film are improved.

[0024] Specifically, the density of the formed graphene foam film should be guaranteed to be 0.05g / cm 3 ~1.4g / cm 3 , ...

Embodiment 1

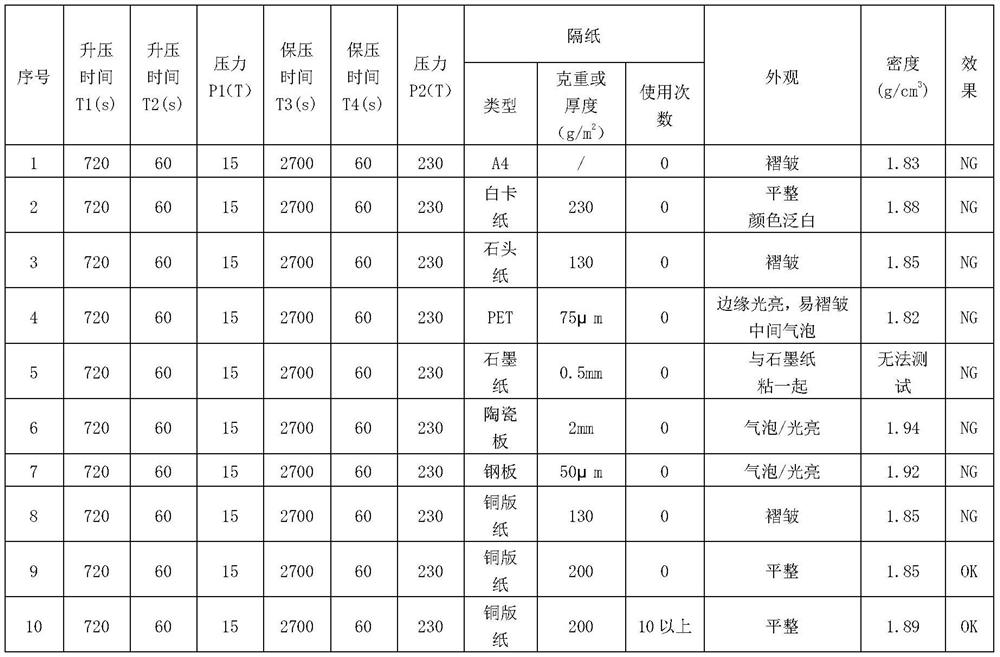

[0031] Thickness 300~400 microns, density 0.18g / cm 3 Graphene foam film, the size is 240*240mm, a piece of paper and a piece of film, stack 10 groups and put them in a 250*250mm iron mold for lamination, under the conditions of vacuum less than 500pa and the same lamination, Observe the appearance and test the density, the specific results are as follows:

[0032]

[0033] From the above results, it can be seen that the thin A4 paper, stone paper and PET are easy to wrinkle, and the white cardboard has good flatness, but the surface color of the prepared thermal conductive film is white and polluted; the graphite paper and the product are stuck together and cannot be used; the steel plate And the PET surface is smooth and the exhaust is not good enough, 200g / m 2 The coated paper is better in terms of air release and appearance uniformity as a paper separator. That is, the separator is one of coated paper and metal plate.

Embodiment 2

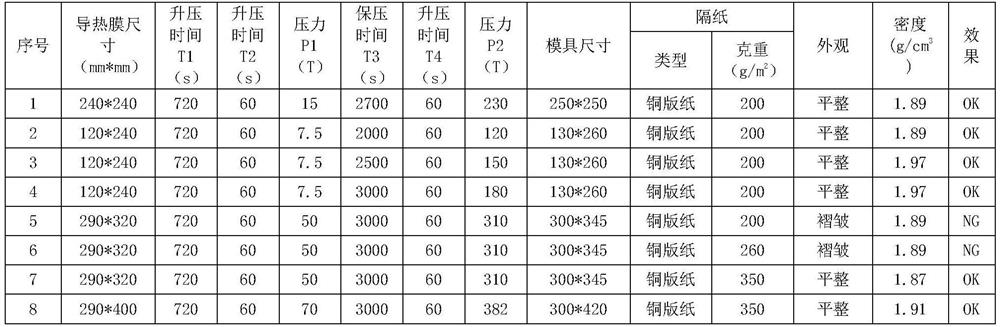

[0035] Thickness 500~600 microns, density 0.18g / cm 3 Graphene foam film, a piece of coated paper and a piece of film, stack 300 groups and put them into iron molds of different sizes for lamination, lamination under the condition that the vacuum degree is less than 500pa, and take 3 sheets to test the density after lamination, The specific results are as follows:

[0036]

[0037] Pressure increased from 40Mpa to 62Mpa, density increased from 1.89 to 1.97g / cm 3 . It can be seen from the serial numbers 1, 5, 6, 7, and 8 that with the increase of the size of the mold, the coated paper needs to have a larger gram weight to ensure that the thermal conductive film does not wrinkle, that is, the grams of the coated paper and the size of the mold proportional.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com