Anti-dry protection device for electromagnetic oven cooker

A protection device, anti-dry-burning technology, applied to household appliances, household stoves/stoves, electric heating fuels, etc., can solve problems such as falling off, hidden dangers, affecting appearance, and achieve fast induction, accurate judgment and protection, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples.

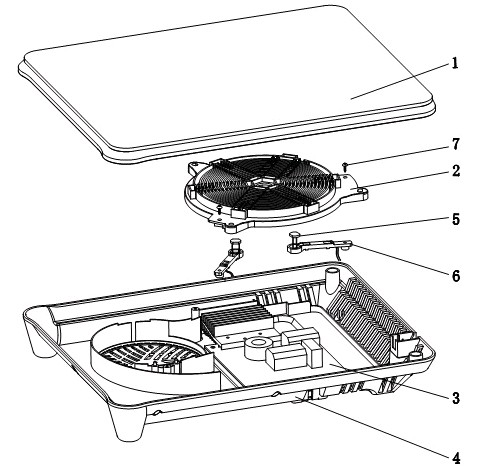

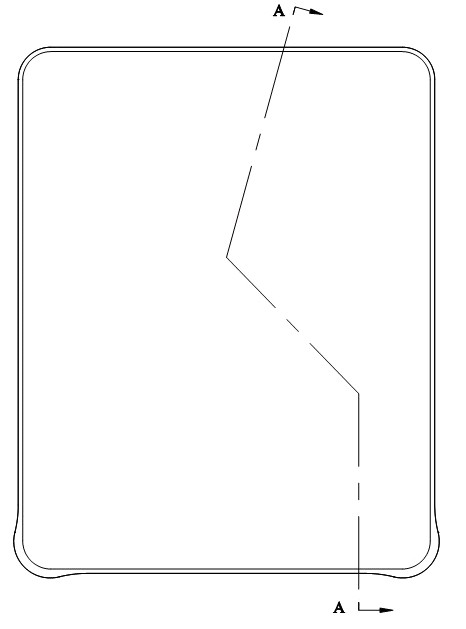

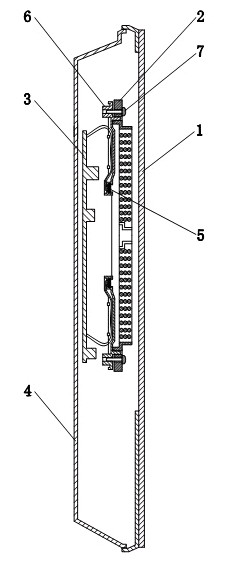

[0022] Such as figure 1 , figure 2 , image 3 As shown, the anti-dry burning protection device for electromagnetic cooker pots of the present invention includes a light-transmitting panel 1, a coil plate 2, a main control board 3, a base 4, and two photosensitive sensors that can induce changes in resistance due to dry-burning of pots and utensils. Component 5 and two photosensitive element brackets 6, wherein the coil disk 2 and the main control board 3 are installed in the base 4, and the two photosensitive element brackets 6 are installed under the coil disk 2, and one end thereof is fixed on the bracket of the coil disk 2 , the other end is located under the heating area of the light-transmitting panel 1, and the photosensitive element 5 is clamped in the other end of the photosensitive element bracket 6, which is just lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com