Automatic grid density generation method applicable to finite element analysis during forging process

A mesh density, automatic generation technology, applied in special data processing applications, instruments, calculations, etc., can solve finite element mesh distortion, difficult to control the number of mesh model elements, difficult to achieve mesh refinement automation and adaptability and other problems to achieve the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the drawings and embodiments.

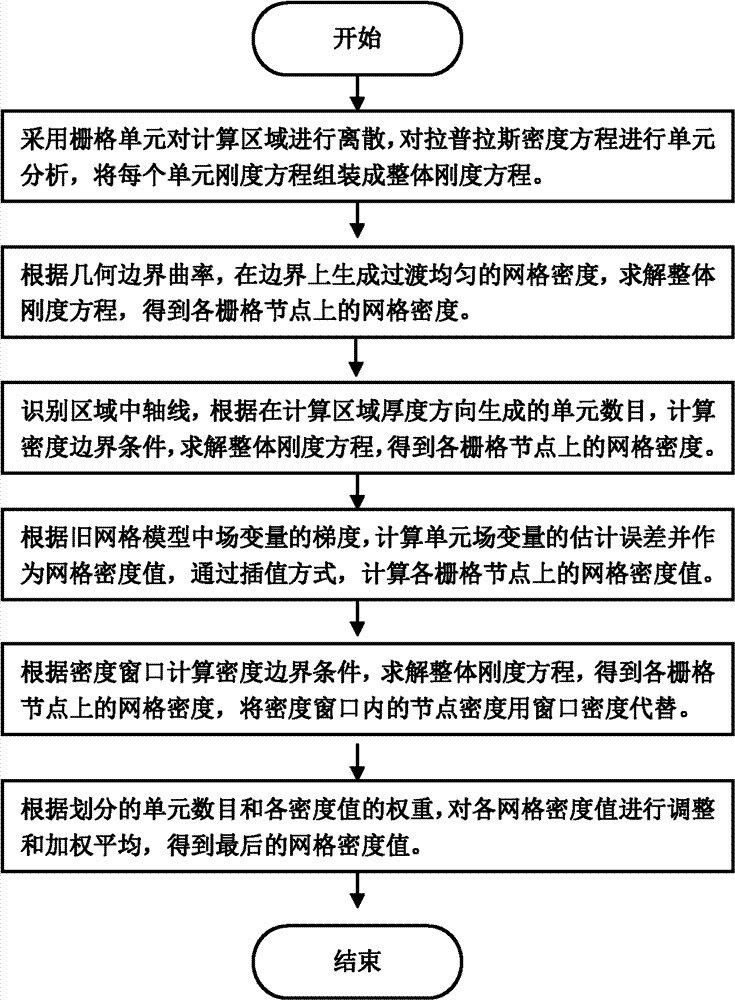

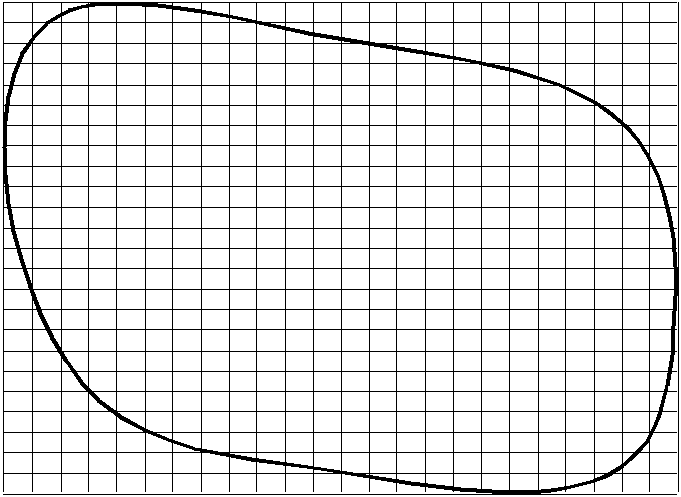

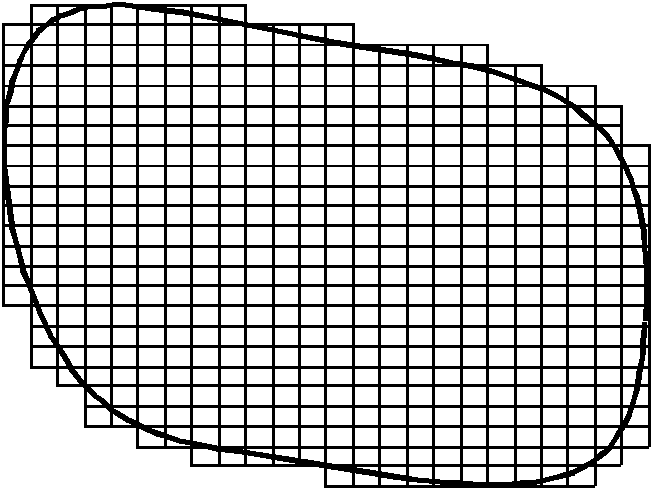

[0051] figure 1 The flow chart is automatically generated for the finite element mesh density of the forging process. according to figure 1 As shown, the automatic generation process of finite element mesh density is as follows: use grid cells to discretize the calculation area, perform grid cell analysis on the Laplace density equation, obtain the grid cell stiffness equation, and assemble the element stiffness equation into a whole Stiffness equation; according to the curvature of the geometric boundary, a uniform mesh density is generated on the boundary, and the boundary mesh density is applied as a boundary condition to the grid boundary nodes, and then the overall stiffness equation is solved to obtain the grid on each grid node Density value; using image processing technology to identify the central axis of the calculation area of the forging, calculate the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com